In the heart of every grain lies the potential for nourishment, economic growth, and culinary exploration. Rice, often referred to as the staple of life for billions, transcends mere sustenance; it embodies culture, tradition, and innovation. As the global demand for rice continues to rise, so does the need for efficient processing methods that unlock the grain’s full potential. Enter the world of rice processing equipment—a realm where technology meets tradition, transforming raw grains into a myriad of forms, from fluffy bowls of steamed rice to the delicate flour that serves as a foundation for an array of dishes. This essential guide delves into the intricacies of rice processing equipment, exploring the machinery that makes this transformation possible, the innovations driving efficiency in the industry, and the impact of these advancements on quality and sustainability. Join us as we navigate the journey from paddy to plate, revealing the hidden complexities and essential tools that ensure rice remains an enduring staple on tables around the world.

Understanding the Rice Processing Journey from Field to Fork

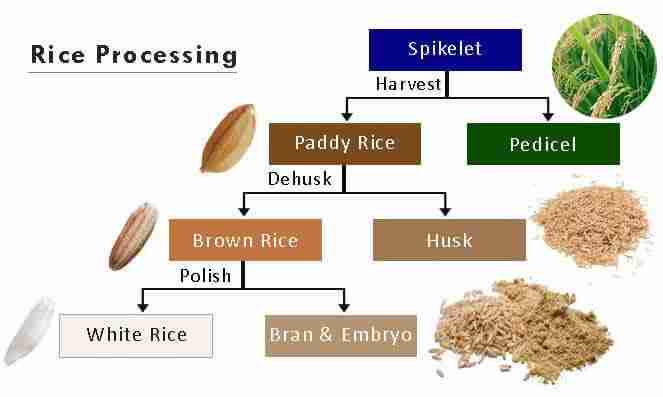

The journey of rice from the fields to dining tables is a captivating process that involves several stages, each requiring specific equipment to ensure that the grains maintain their quality and taste. After rice is harvested, the first step in processing involves drying the grains to reduce their moisture content. This is crucial because excess moisture can lead to spoilage. Equipment such as grain driers and sun driers are vital in this phase to ensure the rice is adequately dried. Following drying, the rice undergoes cleaning, where impurities such as stones, husks, and other foreign materials are removed using cleaning machines that utilize screens and air separators for effective removal, pivotal for maintaining product integrity.

Once cleaned, the rice enters the milling phase, where it is processed into a form suitable for consumption. This stage predominantly involves hulling and polishing. The hulling process removes the outer husk of the rice, while polishing involves refining the grains for better appearance and taste. Machinery like rice huskers and polishing machines play integral roles here. A simplified view of this processing journey can be displayed in the table below, illustrating the key steps and associated equipment:

| Stage | Key Equipment |

|---|---|

| Drying | Grain Drier, Sun Drier |

| Cleaning | Cleaning Machine |

| Milling | Rice Husker, Polishing Machine |

Each of these stages requires precision and efficiency, showcasing the need for advanced technology in the rice processing sector. Adopting innovative machinery not only streamlines the workflow but also enhances the flavor profile and nutritional value of the final product. The evolution of rice processing represents a blend of tradition and technology, transforming simple grains into staples that grace tables worldwide.

Key Equipment for Efficient Rice Milling and Polishing

In the world of rice processing, having the right machinery is crucial for achieving optimal results. Central to this is the rice mill, which serves as the backbone of the operation, transforming raw, unprocessed grains into ready-to-cook rice. The mill typically includes a series of integral components designed to remove husks, separate bran, and ultimately yield polished grains. Some vital equipment involved in this process includes:

- Husker: Efficiently removes the outer husk from the paddy.

- Sheller: Separates rice from empty husks to ensure quality rice output.

- Paddy Separator: Uses density differences to separate whole kernels from broken grains.

- Polisher: Enhances the appearance of rice by polishing the surface and improving marketability.

To achieve consistent and efficient milling, it’s necessary to maintain proper settings and calibrations for each piece of equipment. Additionally, the integration of advanced technologies, such as laser sorting machines, adds a layer of quality control that enhances the final product. Below is a simplified overview of some key aspects that should be considered when selecting equipment for rice processing:

| Equipment | Function | Benefits |

|---|---|---|

| Husker | Removes husk from paddy | Higher output efficiency |

| Polisher | Enhances appearance | Improved market value |

| Laser Sorter | Quality control of grains | Reduced defects in final product |

Innovative Technologies Enhancing Rice Quality and Yield

Advancements in technology have dramatically transformed how rice is cultivated and processed, ultimately enhancing both quality and yield. Modern agricultural techniques such as precision farming utilize drones, GPS-guided tractors, and sensor technology to monitor crop health in real-time. This allows farmers to make informed decisions about irrigation and fertilization, leading to greater efficiency and reduced waste. On the processing side, innovations like high-tech milling systems and automatic sorting machines ensure that rice is not just produced in quantity but also in quality, eliminating broken grains and minimizing contamination.

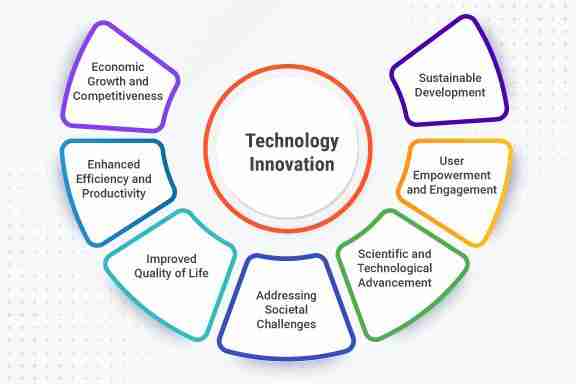

Moreover, biotechnological innovations have unlocked new possibilities for rice varieties that are more resilient to pests and diseases. Techniques like CRISPR gene editing can enhance specific traits in rice plants, resulting in varieties that are not only higher-yielding but also better suited to withstand climate fluctuations. The integration of artificial intelligence in agriculture can also predict harvest outcomes, optimize supply chains, and improve market access. The cumulative effect of these innovative technologies is a robust rice industry poised for sustainability and responsiveness to global demands.

Maintenance and Best Practices for Longevity of Processing Equipment

To ensure the longevity of processing equipment in the rice milling industry, it is essential to implement a proactive maintenance program. Routine checks and timely interventions can dramatically extend the lifespan of these machines. Key practices include:

- Regular Inspections: Schedule monthly checks to monitor wear and tear on moving parts.

- Lubrication: Use high-quality lubricants to reduce friction and prevent overheating.

- Cleaning: Maintain cleanliness by removing rice husks and dust that build up during processing.

- Calibration: Ensure precise alterations as per manufacturer guidelines to optimize performance.

Moreover, fostering a culture of operator training is crucial. Educating staff on the proper use and troubleshooting of equipment helps mitigate the risk of mechanical failures. Establish clear guidelines that emphasize the importance of:

- Safe Operating Procedures: Ensure all operators are well-versed in equipment handling techniques.

- Data Monitoring: Utilize sensors and tools to track performance metrics for early detection of issues.

- Documentation: Maintain an operations manual that includes maintenance logs and operational guidelines.

| Best Practice | Description |

|---|---|

| Routine Maintenance | Perform regular check-ups to anticipate and resolve potential issues. |

| Operator Training | Invest in training programs to enhance operational proficiency. |

| Performance Monitoring | Utilize technology to track and analyze equipment performance. |

Future Outlook

As we wrap up our exploration into the world of rice processing equipment, it’s clear that the journey from grain to nourishment is as intricate as it is vital. The machinery and techniques we’ve discussed not only enhance efficiency but also uphold the quality and sustainability of one of the world’s most cherished staples.

Whether you are a seasoned processor or just stepping into the field, understanding the nuances of these tools can empower you to make informed choices that benefit both your operations and the communities they serve. The future of rice processing is bright, filled with innovation and opportunities that promise to elevate this essential crop to new heights.

As you move forward, remember that each grain transformed is not just a product—it’s a story of culture, resilience, and sustenance. Embrace the technology at your fingertips and let it guide you in your pursuit of excellence in rice processing. Thank you for journeying with us through this essential guide; may your endeavors yield not just grain, but growth and prosperity.