Unlocking Potential: Exploring mini rice mill Plants

Rice, often dubbed the ‘food of the world,’ nourishes billions and serves as a staple in countless cuisines. As we delve deeper into the intricate tapestry of rice production, we find that the journey from paddy to plate is more than just a straightforward process; it’s a complex interplay of technology, tradition, and innovation. One of the unsung heroes in this narrative is the mini rice mill plant—a game-changer that holds the promise of efficiency, accessibility, and sustainability in rice processing.

In this exploration, we will unveil the transformative potential of mini rice mill plants, examining how they empower local farmers, enhance production capabilities, and contribute to rural economies. Beyond mere machinery, these compact facilities symbolize a shift towards localized production and self-sufficiency. Join us as we unlock the potential of mini rice mills and uncover their role in reshaping the future of rice processing and consumption around the globe.

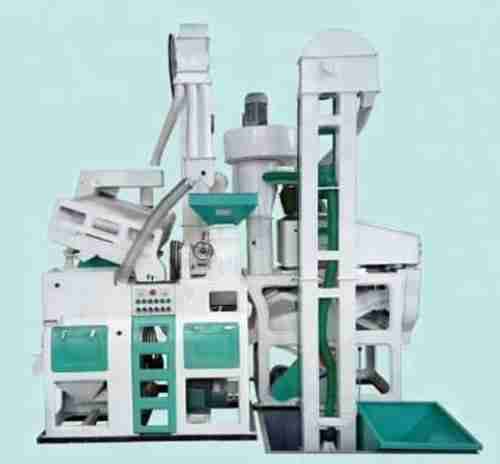

Understanding the Essential Components of mini rice mill Plants

In a mini rice mill plant, understanding the core components is vital for optimizing its operation and ensuring the efficiency of rice processing. Each part plays a strategic role, contributing to the overall success of the mill. The primary components include:

- Dehusking Unit: This unit removes the husk from the paddy, converting it into brown rice.

- Milling Unit: Here, brown rice is polished to produce white rice, enhancing its appearance and market value.

- Grading Unit: It categorizes the rice based on size and quality, ensuring a uniform product for consumers.

- Packaging Station: This component is crucial for the final presentation of the rice, making it ready for sale.

Moreover, the mill’s power supply should be stable and reliable to ensure continuous operation. An efficient water management system is also essential for cooling the machinery during processing. Regular maintenance of these components is key to minimizing downtime and maximizing output. Investing in high-quality materials for the construction of plant units can significantly impact the longevity and efficiency of the operations. The integration of modern technology in these components leads to enhanced precision and higher yield rates.

Navigating Investment Opportunities for Small-Scale Rice Processing

Investing in small-scale rice processing presents a myriad of opportunities that can transform agricultural practices and drive economic growth in rural communities. mini rice mill plants are tailor-made for farmers and entrepreneurs looking to capitalize on the booming demand for processed rice. By mitigating post-harvest losses, these facilities empower local producers to enhance their income while providing consumers with fresher, high-quality products. Furthermore, the relatively low capital requirement associated with setting up these mills makes them an attractive option for those venturing into agribusiness.

To successfully navigate this investment landscape, it’s vital to consider several key factors:

- Market Analysis: Research local and regional markets to understand consumer preferences and pricing trends.

- Technical Expertise: Acquire knowledge about the latest milling technologies and methodologies to ensure efficiency and product quality.

- Funding Options: Explore various financing avenues such as microloans, government grants, or partnerships with agricultural cooperatives.

- Regulatory Compliance: Familiarize yourself with the legal requirements applicable to food processing in your region.

Below is a simplified overview of potential costs and returns associated with establishing a mini rice mill plant:

| Item | Estimated Cost (USD) | Annual Return Potential (USD) |

|---|---|---|

| Equipment Purchase | $15,000 | $30,000 |

| Operating Expenses | $5,000 | – |

| Profit After Costs | – | $25,000 |

With careful planning and an understanding of the market dynamics, potential investors can unlock substantial opportunities in the rice processing sector. By tapping into local resources and fostering community involvement, small-scale facilities can not only thrive but contribute significantly to the larger agricultural ecosystem.

Optimizing Production Efficiency and Quality Control Measures

In the process of transforming raw rice into consumable products, maximizing production efficiency is paramount. mini rice mill plants can significantly streamline operations by integrating modern technology and automated systems. By investing in advanced milling techniques and machinery, operators can achieve higher output rates while reducing energy consumption and waste. Key strategies include:

- Implementing Automation: Utilize automatic feeders and digital controls for precision in monitoring and adjusting milling processes.

- Scheduling Maintenance: Regular maintenance of equipment minimizes downtime and ensures optimal performance.

- Training Operators: Educating staff on best practices boosts productivity and enhances quality control.

Quality control measures are also essential in maintaining the standards of the final product. By establishing a robust framework for inspection and testing, mini rice mills can ensure that each grain meets consumer expectations. Utilizing statistical process control (SPC) techniques can help in monitoring the production and identifying any discrepancies early. Some effective quality control practices include:

| Quality Control Technique | Description |

|---|---|

| Visual Inspection | Regular checks by workers to ensure grains are uniform and free of defects. |

| Moisture Content Testing | Using moisture meters to ensure proper storage conditions and prevent spoilage. |

| Sensory Evaluation | Tasting and evaluating texture for market readiness. |

Sustainable Practices for Future-Proofing Your Rice Mill Venture

To ensure a resilient future for your rice mill operation, integrating eco-friendly methods is vital. Emphasizing sustainability goes beyond compliance; it’s about harnessing resources effectively and reducing waste. Consider implementing the following strategies:

- Energy Efficiency: Invest in energy-efficient machinery that consumes less power and operates at optimal performance levels.

- Water Conservation: Install water recycling systems to minimize usage and reduce environmental impact during the milling process.

- Renewable Energy Sources: Explore solar panels or biomass energy options to power your rice mill, decreasing reliance on fossil fuels.

- Waste Management: Develop a plan for utilizing by-products, such as bran and husks, thus turning waste into profit through secondary products.

Furthermore, collaboration with local communities and stakeholders can bolster these efforts. Engaging in knowledge-sharing and community projects can improve your mill’s social license to operate. Remember, every sustainable initiative has the potential to enhance your brand’s reputation and customer loyalty. Chart your path with measurable goals by evaluating your progress through:

| Goal | Measurable Metric | Timeframe |

|---|---|---|

| Reduce energy consumption | % decrease in monthly energy bills | 12 months |

| Maximize water recycling | Liters of water recycled | 6 months |

| Utilize by-products | Revenue generated from by-products | 12 months |

Insights and Conclusions

As we journeyed through the intricate world of mini rice mill plants, it becomes evident that these compact powerhouses hold the key to transforming both agricultural landscapes and local economies. By unlocking the potential of rice milling, we not only harness the grains of our labor but also empower communities, foster innovation, and promote sustainability. The shift towards these efficient, small-scale operations symbolizes a pivotal change in how we approach food production—one that marries tradition with technology.

As this exploration comes to a close, we invite you to envision the possibilities that lie ahead. Whether you are a farmer seeking to elevate your yield, an entrepreneur aiming to make your mark, or simply an advocate for sustainable practices, the mini rice mill plant offers a fertile ground for growth and opportunity. it is not just about milling rice; it is about milling dreams into reality—one grain at a time. So, let us embrace this potential, fostering a future where prosperity is accessible to all.