In a world where efficiency and sustainability are at the forefront of agricultural innovation, mini rice mill plants stand out as beacons of modernity and practicality. These compact, yet powerful machines are transforming the rice milling landscape, making it easier for smallholder farmers and entrepreneurs to access the full potential of their harvests. With the ability to process rice with minimal waste and maximized yield, mini rice mills not only empower local economies but also contribute to the overall stability of food supply chains. This article embarks on a comprehensive exploration of mini rice mill plants, examining their design, functionality, and the myriad benefits they offer to communities worldwide. Join us as we unlock the secrets to cultivating efficiency in rice production and discover how these innovative solutions are reshaping the future of agriculture.

Understanding the mini rice mill Plant Ecosystem

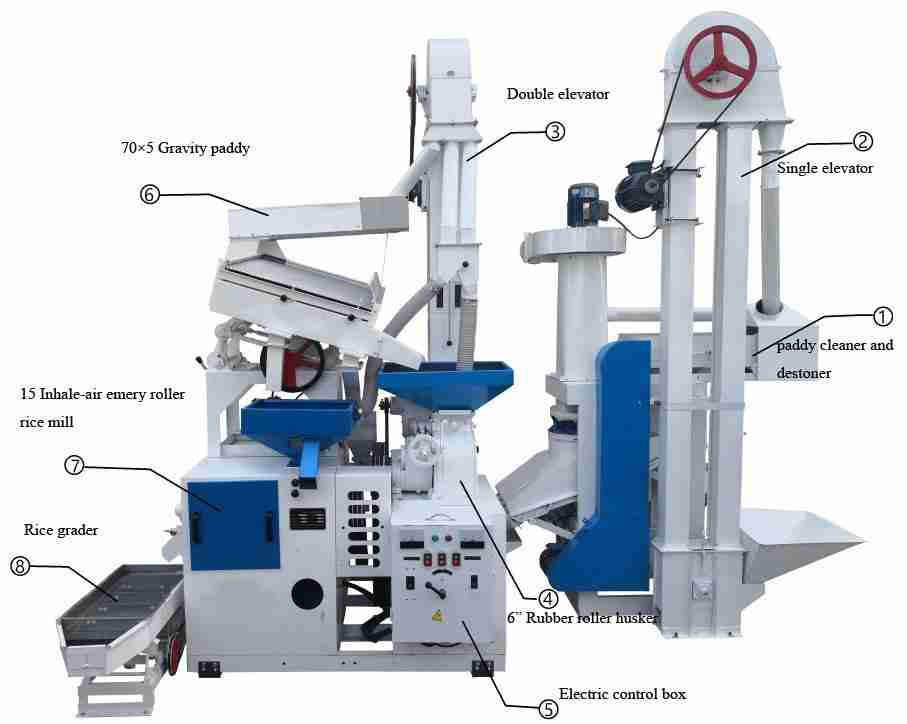

When exploring the intricacies of a mini rice mill plant, it’s essential to appreciate the interplay between the various components that make up its ecosystem. At the heart of this system lies the machinery, which includes equipment for husking, milling, and polishing rice. Each piece of equipment works harmoniously to ensure that raw paddy is transformed into high-quality rice efficiently. Beyond machinery, the human element plays a crucial role; skilled operators are essential for ensuring smooth operations, maintenance, and optimal productivity. The synergy between technology and skilled labor creates a seamless flow of processes, contributing significantly to overall efficiency.

Equally important is the supply chain management that surrounds mini rice mill plants. This includes sourcing high-quality paddy, managing inventory, and distribution logistics. A well-structured supply chain can enhance the freshness of the final product and minimize wastage. Among the other key aspects of this ecosystem are market dynamics and community engagement. Understanding local demand and consumer preferences allows mill operators to tailor their output accordingly, while fostering good relationships with local farmers ensures a consistent flow of raw materials. The interconnectedness of these elements creates a robust framework that not only supports the operational side of the plant but also strengthens its position in the local economy.

| Component | Role |

|---|---|

| Machinery | Transforms paddy into polished rice |

| Human Resources | Operates machinery and manages processes |

| Supply Chain | Ensures raw material availability and distribution |

| Market Dynamics | Guides production based on consumer demand |

| Community Engagement | Builds relationships with local farmers |

Key Technologies Driving Efficiency in Mini Rice Mills

In the realm of mini rice mills, several cutting-edge technologies are revolutionizing operational efficiency. These innovations play a crucial role in maximizing output while minimizing waste and resource consumption. Key advancements include:

- Automated Milling Systems: These systems utilize sophisticated sensors and AI algorithms to optimize the milling process, ensuring uniform grain size and quality.

- Energy-efficient Motors: The latest energy-efficient motors not only reduce electricity consumption but also enhance the longevity of the equipment.

- Quality Control Software: Integrated monitoring systems track grain quality in real time, allowing for immediate adjustments and reducing spoilage.

- Eco-friendly Waste Management: Technologies that convert husk and other by-products into usable energy or compost are becoming standard, supporting sustainability within the milling process.

Moreover, the implementation of IoT (Internet of Things) devices allows for remote monitoring and control of equipment, leading to unprecedented levels of operational transparency. By adopting digital dashboards, mill operators can easily track production metrics and identify areas needing improvement. An example of how technology is reshaping the industry can be seen in the efficiency comparison of traditional vs. modern mini rice mills:

| Parameter | Traditional Rice Mill | Modern mini rice mill |

|---|---|---|

| Processing Time (Hours) | 10 | 5 |

| Energy Consumption (kWh) | 50 | 30 |

| Grain Loss Percentage | 10% | 2% |

Optimizing Operations for Maximum Output and Profitability

In the journey toward enhanced productivity, mini rice mill plants can significantly transform operational dynamics. By leveraging modern technology, these mills reduce processing time while enhancing output quality, ultimately leading to cost savings. Key strategies include:

- Streamlined processing: Implementing automated systems minimizes manual errors and speeds up production cycles.

- Resource optimization: Utilizing energy-efficient machines cuts down on energy costs.

- Quality control: Establishing rigorous quality assurance processes ensures consistently high-quality rice, increasing consumer trust and marketability.

Another essential aspect of running a successful mini rice mill plant is managing supply chain logistics effectively. Efficient procurement of raw materials and distribution of finished products can make a substantial difference in profitability. Consider the following practices:

| Practice | Description |

|---|---|

| Supplier Relationships | Nurturing partnerships with local farmers ensures a steady supply of paddy. |

| Inventory Management | Implementing just-in-time inventory systems to reduce excess stock and minimize waste. |

By focusing on operational efficiency through technology and strategic supply chain management, mini rice mills can achieve a remarkable balance between output and profitability, ensuring not just survival but thriving in a competitive market.

Sustainable Practices for Future-Proofing Rice Milling Operations

Implementing sustainable practices in rice milling not only contributes to environmental preservation but also enhances operational efficiency and profitability. Utilizing renewable energy sources, such as solar panels, to power mini rice mill plants can significantly reduce carbon footprints while lowering operational costs. Additionally, investing in energy-efficient machinery is crucial. Key upgrades might include the installation of modern rice polishers that use less water and consume less energy, thereby streamlining the milling process.

Moreover, reducing waste is paramount for a sustainable approach to rice milling. One effective method is to repurpose byproducts generated during milling, such as rice husks and bran. These materials can be transformed into valuable products such as biofuel, animal feed, or even health supplements. To facilitate this, consider establishing partnerships with local businesses for shared waste management solutions. A collaborative framework can help minimize waste while opening new revenue streams. Here’s a brief overview of potential byproducts and their uses:

| Byproduct | Potential Uses |

|---|---|

| Rice Husks | Biofuel, Building materials, Fertilizer |

| Rice Bran | Animal Feed, Health Supplements, Cooking Oil |

| Polishing Waste | Compost, Bioactive Products |

The Way Forward

As we conclude our exploration of mini rice mill plants, it’s clear that these compact yet powerful facilities hold the key to unlocking greater efficiency in rice production. From reduced operating costs to minimal space requirements, the advantages are plentiful for small-scale farmers and entrepreneurs alike. The technological advancements in design and operation are not only enhancing productivity but also promoting sustainability and local economies.

As the world continues to seek innovative solutions to meet the ever-growing demand for food, mini rice mill plants stand out as a beacon of possibility. They empower communities, bolster food security, and pave the way for agricultural modernization. By investing in such technologies, we are not just improving the rice milling process; we are laying the groundwork for a more resilient agricultural future.

In this journey towards efficiency, let us remain committed to embracing the changes that these mini mills represent. As we cultivate the potential within our agricultural systems, may we also nurture the relationships they foster and the livelihoods they support. With every grain that passes through these mills, we contribute to a larger narrative of progress, innovation, and sustainability. So, whether you’re a farmer, a policymaker, or an enthusiast, the call to action is clear: let’s continue to unlock efficiency and drive the next wave of agricultural advancement together.