Unlocking the Grain: The Essential Role of Rice Mills Today

In an age where culinary trends often overshadow the fundamental staples of our diets, rice stands as a timeless foundation for many cultures around the globe. Yet, behind the humble grain lies a vital industry often taken for granted—the rice mill. These facilities are more than mere processing plants; they are the unsung heroes of food production, transforming raw paddy into the versatile rice varieties that grace our tables. As the demand for sustainable practices and nutritious food sources rises, understanding the intricate workings of rice mills becomes increasingly crucial. This article delves into the essential role of rice mills today, exploring their impact on economies, communities, and the very nature of food security. Join us as we uncover the hidden world of grain unlocking and its significance in our rapidly evolving culinary landscape.

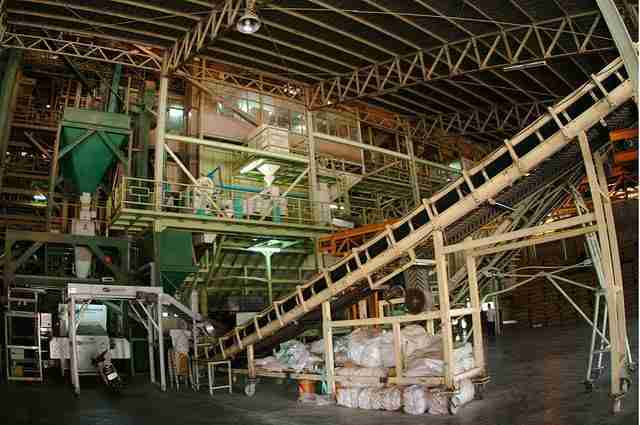

Exploring the Evolution of Rice Milling Technology

Over the centuries, rice milling technology has undergone remarkable transformations, shaping not only how rice is processed but also its role in global food security. In ancient times, labor-intensive methods such as manual pounding and husking strips of rice were the norm. With the dawn of the Industrial Revolution, innovations like the water-powered mill and mechanical huskers emerged, significantly increasing efficiency. These developments marked the beginning of a shift towards more sophisticated machinery, paving the way for modern milling techniques that use advanced technology to enhance both productivity and product quality. Today, practices such as two-step milling and integrated pest management are employed to reduce waste and promote sustainability in rice production.

The evolution of rice milling technology has also embraced automation, providing benefits that extend beyond mere efficiency. Modern rice mills often feature computerized systems that allow for precise control over milling parameters, ensuring consistent quality and minimizing the potential for contamination. Alongside traditional techniques, today’s milling practices utilize sensors and AI-driven analysis to monitor grain conditions, optimizing processes in real-time. Various technologies currently shape the future of rice milling:

- Small-scale mobile mills for rural areas

- Solar energy-powered machines to reduce carbon footprints

- Division and grading machines to ensure uniformity in grain size

| Technology Era | Key Features |

|---|---|

| Ancient Methods | Labor-intensive, manual operation |

| Industrial Revolution | Mechanical huskers, increased efficiency |

| Modern Automation | Computerized control, waste reduction |

Economic Impact of Rice Mills on Local Communities

Rice mills serve as a crucial economic backbone for local communities, stimulating growth and fostering self-sustainability. By providing job opportunities both directly and indirectly, these mills enable families to thrive and invest in their futures. When rice is processed at the local level, it not only reduces transportation costs but also enhances the profit margin for farmers, allowing them to reinvest in their agricultural practices. The presence of rice mills supports a multitude of ancillary businesses, from suppliers of machinery and spare parts to transport services and retail outlets dealing in agricultural products, creating a robust local economy.

The benefits of rice mills extend beyond mere economic support; they also promote social development. By engaging the community, these establishments often participate in educational initiatives, promoting awareness about sustainable farming practices and food security. Community engagement initiatives can include:

- Workshops on crop management and sustainable farming techniques.

- Training programs for local youth, equipping them with skills valuable for employment.

- Support for local farmers, ensuring they have access to markets and fair prices.

| Economic Benefits | Social Benefits |

|---|---|

| Job creation | Community workshops |

| Increased local investment | Educational outreach |

| Support for ancillary businesses | Skill development programs |

Sustainable Practices in Modern Rice Processing

Modern rice processing has undergone a remarkable transformation, with sustainability taking center stage in the operations of rice mills worldwide. By integrating eco-friendly practices, these facilities are not only enhancing their productivity but also minimizing their environmental impact. Key methods include:

- Water Conservation: Implementing water-efficient techniques such as recirculating systems and rainwater harvesting to reduce excessive water use.

- Energy Efficiency: Upgrading to energy-efficient machinery and utilizing renewable energy sources like solar and biomass to power processing operations.

- Waste Reduction: Recycling husk and bran by-products to create biofuels or organic fertilizers, thus reducing waste and fostering a circular economy.

Furthermore, the adoption of advanced technologies plays a pivotal role in sustainable rice processing practices. Automation and digital monitoring systems facilitate precise resource management, leading to reduced waste and improved operational efficiency. This technological shift not only drives the mills toward sustainability but also elevates product quality. Key benefits of these innovations include:

| Benefit | Description |

|---|---|

| Enhanced Quality | Use of automated sorting and grading to ensure only the best grains are processed. |

| Operational Savings | Reduced energy and water costs through smart technology integration. |

| Market Competitiveness | Ability to meet growing consumer demand for sustainably sourced products. |

Enhancing Quality Control for Better Rice Production

Implementing rigorous quality control measures is essential to elevate the standard of rice production. By optimizing various stages of processing, from harvesting to milling, rice mills can significantly reduce waste and enhance the quality of the final product. Some effective strategies include:

- Regular Training: Continuous education for workers on best practices in handling and processing rice prevents contamination and injury.

- Advanced Equipment: Utilizing modern machinery with real-time monitoring capabilities allows for immediate detection of defects.

- Quality Audits: Routine inspections and audits help identify areas for improvement within the processing line.

A key aspect of this quality enhancement is the meticulous sorting and grading of rice to ensure only the best grains reach the consumer. By implementing advanced sorting technologies, rice mills can categorize products based on quality, size, and moisture content. This method not only maintains consistency but also maximizes marketability. Below is a simple overview of the grading criteria:

| Grade | Description |

|---|---|

| Premium | High-quality grains with uniform size, minimal defects. |

| Standard | Mixed sizes with few imperfections, suitable for everyday use. |

| Sub-Standard | Contains broken or subpar grains, best for processing into other products. |

Insights and Conclusions

rice mills stand as the unsung heroes in the journey of grains from paddy fields to our plates. They are not merely machinery, but intricate systems that weave together agriculture, technology, and culture, ensuring the vital staple of rice is transformed into a nourishing food source. As we delve deeper into the complexities of food production and sustainability, the role of rice mills becomes increasingly crucial, adapting to modern challenges while preserving age-old traditions. In unlocking the potential of grain, we unlock the potential of communities, economies, and culinary traditions. As we continue to explore the intricate tapestry of global food systems, let us recognize and appreciate the significant contribution of rice mills—not just in producing a vital resource, but in fostering resilience and innovation in the face of a changing world.