In a world where efficiency and sustainability are paramount, the agricultural sector is undergoing a remarkable transformation. Among the myriad of innovations shaping this landscape, the mini rice mill stands out as a beacon of progress. This compact and versatile solution is not just a response to the growing demand for rice processing; it embodies a shift towards more efficient, community-oriented farming practices. As farmers seek ways to increase productivity while minimizing costs and environmental impact, the introduction of mini rice mills is playing a pivotal role. This article explores how this innovative technology is unlocking new levels of efficiency in rice production, benefitting farmers and consumers alike, and paving the way for a more sustainable agricultural future. Join us as we delve into the mechanics, advantages, and far-reaching implications of this ingenious solution.

Exploring the Technological Advancements Behind Mini Rice Mills

The evolution of mini rice mills is a testament to the relentless march of technology in agricultural practices. These compact units have emerged as a game-changer for small-scale farmers, allowing them to process rice with a level of efficiency that was once reserved for larger operations. Powered by advanced mechanization, modern mini rice mills are equipped with features that significantly enhance productivity. Some key advancements include:

- Energy Efficiency: Incorporating energy-saving motors that reduce electricity costs.

- Automated Systems: Utilizing sensors and automatic controls to streamline the milling process.

- Modularity: Offering customizable units that can be tailored to specific processing needs.

- Quality Enhancement: Integrating polishing and grading machines that ensure superior rice quality.

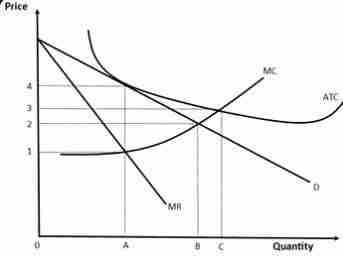

Beyond the immediate advantages of efficiency, the technological advancements in mini rice mills have a profound impact on the economics of rice production. By employing innovative designs and materials, manufacturers have succeeded in creating equipment that is not only durable but also easy to operate and maintain. A comparative analysis of older models versus modern counterparts underscores these improvements:

| Aspect | Older Model | Modern mini rice mill |

|---|---|---|

| Processing Speed | 500 kg/hour | 1200 kg/hour |

| Power Consumption | 15 kW | 7 kW |

| Operator Skill Required | High | Low |

| Footprint | Large | Compact |

This shift not only increases the feasibility of rice milling operations for smaller enterprises but also contributes to the overall sustainability of agricultural practices by minimizing waste and optimizing resource use.

Harnessing Sustainability: Eco-Friendly Benefits of Mini Rice Milling

The introduction of mini rice milling technologies offers a transformative approach to sustainable agriculture, significantly reducing the environmental footprint associated with traditional milling processes. Reduced Energy Consumption is one of the most striking benefits, as these compact machines utilize less power compared to their larger counterparts. Furthermore, mini rice mills often use locally sourced materials, which minimizes transportation emissions and promotes local economies. This alignment with eco-friendly practices not only meets consumer demand for greener products but also fosters a deeper connection between the community and sustainable farming.

Additionally, mini rice milling contributes to waste reduction through by-product utilization. The husks and bran generated during milling can be repurposed as organic fertilizers or animal feed, closing the loop on waste management in rice production. This process not only enriches soil health but also enhances biodiversity within farming ecosystems. As farmers harness these technologies, they can significantly lower their overall carbon emissions, contributing positively to the climate crisis while ensuring a viable livelihood. The integration of mini rice mills into agricultural practices stands as a prime example of innovation aligning with ecological responsibility.

Maximizing Output: Best Practices for Efficient mini rice mill Operations

To enhance productivity in mini rice mill operations, considering the layout of the facility is essential. A well-organized workspace reduces unnecessary movement and streamlines processes. Implementing a flow that minimizes backtracking can dramatically speed up operations. Furthermore, investing in adequate training for staff ensures that all employees are familiar with the machinery and processes, leading to fewer mistakes and swift corrections. This results in less downtime and higher quality output.

Another effective practice involves utilizing modern technology to monitor and analyze production efficiency. Key performance indicators (KPIs) should be established and tracked to identify bottlenecks. Regular maintenance of equipment keeps machinery running smoothly, preventing unexpected breakdowns. The following table outlines some critical KPIs to monitor for optimized performance:

| Key Performance Indicator | Description | Target Value |

|---|---|---|

| Output per hour | Amount of rice processed | 500 kg |

| Downtime | Time machinery is not operational | Less than 5% |

| Quality Yield | Percentage of high-quality rice produced | Above 95% |

By implementing these strategies, mini rice mill operators can significantly enhance their output, ensuring they meet the rising demand for quality rice products.

Empowering Small Farmers: Strategies for Adoption and Integration

Smallholder farmers often face hurdles in efficiently processing their crops, leading to significant post-harvest losses. To bridge this gap, mini rice mills have emerged as a game-changing solution. By facilitating easy access to modern milling technology, these compact machines empower farmers to take control of their production processes. *Training workshops* can be organized to help farmers understand the operational benefits of these mills, enabling them to enhance productivity through improved milling techniques. Additionally, community support networks can inspire collaboration for shared usage, reducing isolation and fostering a spirit of collective growth.

Furthermore, integrating these mills into existing agricultural frameworks can be achieved through targeted financial assistance. Local governments and NGOs can offer *subsidies* or *micro-loans* specifically aimed at acquiring mini rice mills. This investment can foster operational sustainability and profitability for small farmers. To visualize the impact, consider the following table showcasing potential benefits of mini rice mill adoption:

| Benefit | Description |

|---|---|

| Reduced Post-Harvest Losses | Minimizes milling time, preserving grain quality. |

| Increased Income | Allows farmers to sell higher quality, value-added products. |

| Community Empowerment | Encourages collaboration and knowledge sharing among farmers. |

| Cost-Effective Operation | Lower milling costs compared to traditional, larger mills. |

Key Takeaways

In a world where efficiency and sustainability are paramount, the innovative mini rice mill solution stands as a beacon of progress. By harnessing cutting-edge technology and streamlining production processes, this compact powerhouse not only elevates the quality of rice but also empowers smallholders and rural communities. As we embrace the future of agriculture, the mini rice mill serves as a reminder that transformation can begin at the grassroots level. With its potential to reduce waste, lower costs, and enhance livelihoods, this small yet mighty machine is unlocking a new era in rice production. As we continue to explore and implement innovative solutions, the journey towards a more efficient and sustainable agricultural landscape is just beginning. Together, let us cultivate change, one grain at a time.