In a world where convenience and efficiency reign supreme, the agricultural sector is no stranger to innovation. Among the many advancements transforming the landscape of food production, the compact mini rice milling machine stands out as a beacon of ingenuity. This remarkable device not only streamlines the rice milling process but also empowers small-scale farmers and rural entrepreneurs to enhance their productivity and profitability. As we delve into the features and benefits of this revolutionary technology, we will explore how it is reshaping grain processing and contributing to sustainable agricultural practices. Join us on this journey to understand the impact of the compact mini rice milling machine on the grains industry and the lives of those who depend on it.

The Evolution of Rice Milling Technology and Its Impact on Agriculture

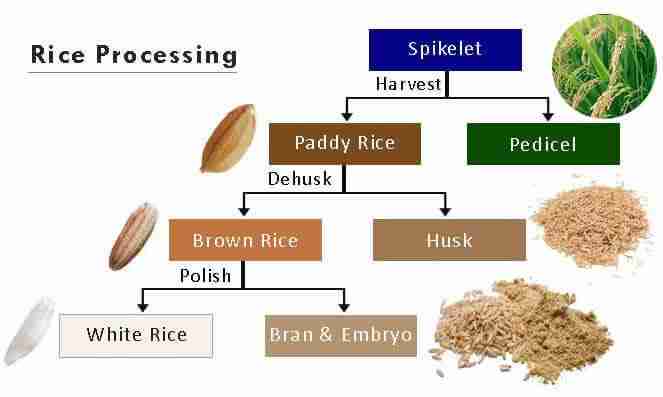

The journey of rice milling technology has undergone significant transformations, leading to enhanced efficiency and productivity in the agricultural sector. Initially dominated by traditional methods that relied heavily on manual labor, the introduction of mechanized milling systems marked a pivotal shift. The compact mini rice milling machine represents the latest advancement in this evolution, offering a range of benefits that cater to both small-scale and large-scale farmers. With its ability to process rice quickly and with minimal power consumption, these machines have enabled producers to meet the growing global demand for rice.

Innovation in rice milling technology has also had a profound impact on the quality of output. Using advanced techniques such as rubber roll milling and polishing mechanisms, today’s machines ensure lower breakage rates, superior grain quality, and enhanced nutritional value. Farmers can now enjoy the following advantages:

- Increased Efficiency: Faster milling times reduce post-harvest losses.

- Improved Quality: Enhanced husking and polishing results in higher-grade rice.

- Cost-Effectiveness: Reduced labor and operational costs boost profitability.

As the agricultural landscape continues to evolve, the adoption of compact mini rice milling machines symbolizes a shift toward sustainable practices, enabling farmers to maximize their yields while minimizing their environmental impact.

Key Features and Benefits of the Compact Mini Rice Milling Machine

The Compact Mini Rice Milling Machine is a game-changer for small-scale farmers and grain processors seeking efficiency and quality in rice production. Its innovative design allows users to transform paddy into perfectly milled rice within minutes, dramatically improving productivity compared to traditional milling methods. This machine not only saves time but also minimizes labor costs, making rice milling accessible and profitable for a broader audience. The versatility of the machine extends beyond rice, accommodating various grains such as wheat and millet, thereby catering to different processing needs in one compact unit.

One of the standout features is its user-friendly interface, ensuring that even those with minimal technical skills can operate it with ease. The machine incorporates energy-efficient technology, which significantly reduces power consumption while maintaining optimal performance. Additionally, its portable structure allows for easy transportation, making it ideal for remote locations. With built-in safety mechanisms, it provides peace of mind for operators. Here’s a quick overview of its specifications:

| Feature | Specification |

|---|---|

| Processing Capacity | Up to 200 kg/hour |

| Motor Power | 1.5 kW |

| Weight | 150 kg |

| Dimensions | 70 x 80 x 120 cm |

By streamlining the milling process, the Compact Mini Rice Milling Machine empowers farmers to retain maximum nutritional value and quality in their grains, all while enhancing their market competitiveness. The reliability and durability of this machine are attributes that assure users of its long-term value, transforming rice milling into a more economical and sustainable practice.

Sustainable Practices: How Mini Mills Contribute to Eco-Friendly Grain Processing

As the world increasingly prioritizes sustainability, mini mills are stepping up to the plate by offering a more eco-conscious method for grain processing. These compact machines utilize significantly less energy compared to traditional milling systems, making them an environmentally friendly choice for small-scale farmers and rural communities. Their design promotes efficiency, which not only reduces operational costs but also minimizes carbon footprints. Lower energy consumption, reduced waste, and less water usage are just a few of the ways mini mills contribute to a more sustainable agricultural ecosystem.

Moreover, mini mills support local economies by empowering farmers to process their grains on-site, which cuts down on transportation emissions and the overall supply chain footprint. By enabling rural producers to access milling technology, these machines encourage community resilience and foster a closer connection between growers and consumers. The integration of sustainable practices at the grassroots level ensures that the benefits of eco-friendly grain processing are felt directly in the communities that cultivate and consume these vital resources. The ripple effect is profound, contributing to food security while simultaneously honoring environmental stewardship.

Maximizing Efficiency: Best Practices for Operating and Maintaining Your mini rice mill

To achieve optimal performance from your mini rice mill, it is essential to establish a regular maintenance schedule. Key tasks include conducting thorough inspections of all mechanical components, ensuring that everything is free from dust and debris. Pay close attention to the blades, as well as the hoppers and separators. Investing time in cleaning not only prolongs the lifespan of your machine but also enhances its milling efficiency. Regularly lubricate moving parts with appropriate oils and greases, and replace any worn-out components promptly to avoid unexpected breakdowns.

Utilizing the mini rice mill to its fullest potential involves understanding the right balance of operation and load management. Adjust the feeding rate according to the type and moisture content of the rice to minimize wastage and maximize output. It’s beneficial to follow these best practices:

- Monitor power usage: Ensure that the voltage supply is consistent to prevent motor overheating.

- Keep a maintenance log: Track repairs, replacements, and operational performance for proactive management.

- Train operators: Ensure that everyone involved understands how to use the machine effectively and safely.

| Task | Frequency |

|---|---|

| Clean machine parts | Daily |

| Inspect blades | Weekly |

| Lubricate components | Monthly |

| Replace worn parts | As needed |

To Wrap It Up

In an era where innovation meets necessity, the compact mini rice milling machine stands as a beacon of progress in the grain processing industry. By streamlining operations and enhancing accessibility, it not only empowers small-scale farmers but also champions sustainability and efficiency. As we navigate the complexities of modern agriculture, this ingenious tool offers a glimpse into a future where technology and tradition coexist harmoniously. As the seed of change takes root, we can look forward to a world where quality grains are more than just a dream but an attainable reality for everyone. With every grain milled, we are revolutionizing the way we view food production, ensuring that the fruits of our labor continue to nourish generations to come. As we close this chapter, let us embrace the journey ahead, where compact machines and big ideas pave the way for an even more sustainable tomorrow.