In the relentless quest for food security and sustainability, the spotlight is increasingly directed towards the heart of agricultural innovation: rice processing plants. As one of the world’s staple crops, rice holds immense significance, feeding billions and shaping economies. Yet, behind the scenes of this vital industry lies a pressing challenge—efficiency. In an era marked by rapid technological advancements and shifting consumer demands, the future of rice processing is evolving. Innovations in automation, data analytics, and sustainable practices are not merely enhancing production; they are redefining what it means to transform raw grains into nourishing meals. This article explores the emerging trends and technologies poised to unlock unprecedented efficiencies in rice processing plants, paving the way for a more resilient and sustainable future in the global food landscape. Join us as we delve into the intricacies of these advancements and their implications for farmers, processors, and consumers alike.

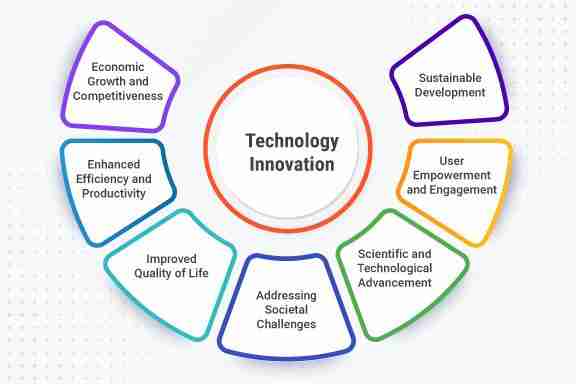

Harnessing Innovative Technology for Enhanced Productivity

As the world evolves, so too must rice processing plants adapt to emerging technologies that can significantly boost productivity and enhance operational efficiency. Implementing automation solutions allows these facilities to streamline processes, reducing human error and increasing output consistency. For instance, smart sensors can monitor moisture levels and grain quality in real-time, adjusting processing conditions to optimal levels. Additionally, incorporating machine learning algorithms enables predictive maintenance, ensuring equipment is serviced before it fails, ultimately saving time and costs.

Moreover, integrating cloud-based management systems empowers rice processing facilities to maintain comprehensive data analytics, providing stakeholders with insights for informed decision-making. The adoption of robotics for packaging further accelerates operations while minimizing labor-intensive tasks. Key technologies that are shaping the future of rice processing include:

- IoT Devices: For real-time monitoring and data collection.

- AI-Driven Analytics: To predict market trends and optimally adjust production.

- Energy-efficient machinery: Reducing operational costs and environmental impact.

By embracing these innovative advancements, rice processors not only improve their production timelines but also create a sustainable and resilient operational framework. The effective implementation of cutting-edge technology promises a transformative shift in processing methods, positioning these plants at the forefront of the agricultural industry.

Integrating Sustainable Practices in Rice Processing Operations

As the global demand for rice surges, integrating eco-friendly practices into processing operations not only aligns with environmental goals but also enhances operational efficiency. By adopting renewable energy sources such as solar and biomass, rice mills can significantly reduce their carbon footprint while lowering energy costs. Additionally, implementing waste minimization techniques can lead to efficient resource management. This includes recycling by-products like rice husks and bran, which can be converted into biofuels or utilized in animal feed, making the entire processing operation more sustainable.

Moreover, incorporating water conservation strategies is vital for sustainable rice processing. Techniques like closed-loop water systems and rainwater harvesting can help facilities manage water usage competently and reduce wastewater generation. Another promising approach is the use of innovative technologies, such as smart sensors and data analytics, to monitor and optimize processing activities. This allows for real-time adjustments that not only enhance productivity but also conserve resources. By investing in both traditional and modern sustainable practices, rice processing operations can pave the way for a greener future while maintaining high output standards.

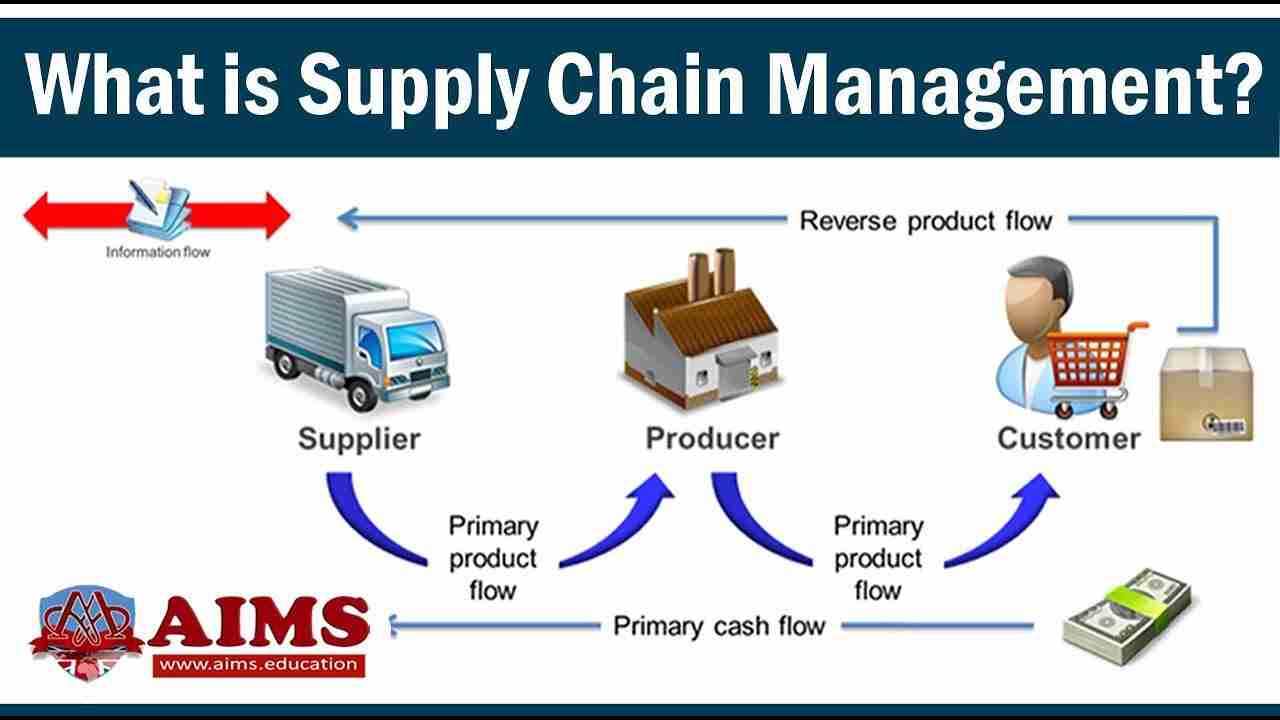

Optimizing Supply Chain Management for Cost Efficiency

In the quest for cost efficiency, rice processing plants must embrace a multifaceted approach to supply chain management. Key strategies involve establishing strong relationships with suppliers to ensure bulk purchasing discounts and consistent quality. By leveraging technology such as blockchain for transparency and efficiency, plants can reduce delays and errors while increasing trust among partners. Additionally, implementing just-in-time inventory practices minimizes storage costs and waste, allowing for a more streamlined processing line.

Furthermore, data analytics can play a pivotal role in optimizing logistics and demand forecasting, which are vital for minimizing excess stock. An effective use of cloud-based solutions can enhance collaboration across the supply chain, enabling real-time updates and improved decision-making. By integrating sustainable practices, such as energy-efficient machinery and waste reduction initiatives, processing plants can not only cut costs but also strengthen their commitment to environmental responsibility. Here is a simple overview of the potential improvements:

| Strategy | Benefit |

|---|---|

| Supplier Collaboration | Lower costs through bulk discounts |

| Blockchain Technology | Enhanced transparency and trust |

| Just-in-Time Inventory | Reduced storage costs |

| Data Analytics | Improved forecasting and logistics |

| Sustainable Practices | Cost reduction and environmental responsibility |

Future-Proofing Facilities with Smart Design and Automation

In the ever-evolving landscape of rice processing, integrating smart design principles and advanced automation technologies can significantly enhance operational efficiency and sustainability. By incorporating modular structures into processing plants, facilities can maintain adaptability, allowing for future expansions or reconfigurations without extensive downtime. This flexibility is crucial in a market that demands quick responses to changing consumer preferences and production methods. Moreover, implementing features such as energy-efficient systems and natural ventilation not only reduces operational costs but also complements environmental sustainability efforts, ensuring that operations align with global standards for eco-friendliness.

Automation is a cornerstone of future-ready rice processing facilities. Employing IoT-enabled machinery provides real-time monitoring and predictive maintenance capabilities, minimizing downtime and enhancing productivity. Furthermore, integrating smart sensors throughout the processing stages can optimize the handling of raw materials, ensuring consistent quality and reducing waste. Leveraging data analytics in production also allows for continual improvement, making it possible to tailor processes to yield the highest efficiency. Below is a comparison showcasing key smart technologies that can be utilized in rice processing plants:

| Technology | Benefits | Impact |

|---|---|---|

| IoT Sensors | Real-time monitoring | Minimized operational downtime |

| Automated Sorting | Increased consistency | Improved product quality |

| Energy Management Systems | Optimized energy consumption | Reduced costs and emissions |

Closing Remarks

As we stand on the precipice of a new era in agricultural technology, the future of rice processing plants promises not only to meet the demands of a growing global population but also to redefine the very nature of food production. By embracing innovative techniques and smart technologies, we unlock the potential for enhanced efficiency, sustainability, and quality in rice processing. As we bid farewell to traditional methods and welcome advanced solutions, the journey of rice from field to table will become increasingly seamless and resource-efficient.

In this dynamic landscape, collaboration among farmers, technologists, and industry leaders will be essential to harness the best practices and innovations. The commitment to continuous improvement and modernization paves the way for a more resilient and sustainable rice industry, one that honors its roots while cultivating a prosperous future. As we look ahead, let us carefully consider not just what we produce, but how we produce it—unlocking the door to a brighter, more efficient future in rice processing.