In the tapestry of human civilization, few grains have woven themselves into the fabric of daily life as profoundly as rice. This staple food, cherished across continents for its versatility and sustenance, has undergone a remarkable transformation throughout history. However, the journey of rice from paddy to plate has not always been seamless. Enter the world of rice processing machines, where innovation meets tradition, revolutionizing how this vital grain is handled. As technology continues to advance, these machines stand at the forefront of agricultural progress, significantly enhancing efficiency, quality, and accessibility. In this article, we delve into the evolution of rice processing technology, exploring how these mechanical marvels have not only transformed production but also reshaped the livelihoods of countless farmers and communities dependent on this essential crop. Join us as we uncover the story behind these machines and their pivotal role in the future of rice processing.

Unveiling the Journey of Rice Processing: From Traditional Techniques to Modern Innovations

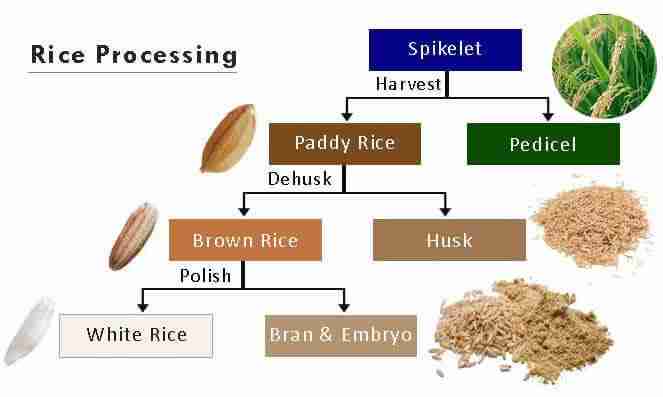

The journey of rice processing begins with deeply rooted traditional methods that have stood the test of time. For centuries, farmers have relied on manual approaches such as hand-pounding and water milling to transform paddy into edible rice. These methods, though labor-intensive, carry cultural significance and showcase the community’s connection to the land. The simplicity of a wooden mortar and pestle or a traditional water wheel reflects an era where every grain was cherished, and sustainability was a way of life. However, with the rise of modernization, there has been a significant shift towards mechanization, paving the way for technologies that enhance efficiency while ensuring quality.

Modern innovations in rice processing machines have revolutionized the industry, introducing efficiency, precision, and scalability. Today’s processing plants utilize advanced technology such as automated huskers, dryers, and whirlwind separator systems to optimize the production process. These machines are designed to minimize waste, maximize yield, and preserve the nutritional integrity of rice. With features like computerized controls and real-time monitoring, rice processing has become less labor-dependent and more data-driven. The following table highlights key innovations and their benefits:

| Technology | Benefits |

|---|---|

| Automated Huskers | Efficient removal of husk, reducing manual labor |

| Continuous Dryers | Even moisture control, improving shelf life |

| Color Sorters | Enhanced quality control, removing discolored grains |

| Grain Cleaners | Effective removal of impurities, boosting product quality |

Integrating Technology: The Role of Automation in Enhancing Rice Quality and Efficiency

In the realm of rice processing, automation serves as a transformative force that enhances both quality and efficiency. By implementing smart systems, rice mills can achieve precision in operations that were once heavily reliant on manual labor. Automated sorting machines now utilize advanced optical sensors to detect and separate grains, ensuring uniformity in size and quality. This not only minimizes human error but also significantly speeds up the sorting process. Additional mechanisms, such as automated paddy huskers and rice polishers, employ integrated technologies that fine-tune pressure settings, resulting in less breakage and more polished grains, ultimately leading to a better product for consumers.

Moreover, automation fosters a data-driven approach to rice processing. Utilizing Internet of Things (IoT) devices, rice mills can now monitor equipment performance and environmental conditions in real-time. This capability allows for the identification of inefficiencies and potential faults before they escalate into significant problems. Key advantages of automated rice processing include:

- Increased throughput: Automating repetitive tasks maximizes productivity.

- Enhanced quality control: Precise adjustments lead to greater product consistency.

- Resource optimization: Automation minimizes waste of raw materials.

- Labor ease: Reducing manual interventions lowers labor costs and fatigue.

As mills continue to embrace these innovative technologies, their ability to produce high-quality rice at competitive costs solidifies their place in the global market. With automation at their core, rice processors are not only improving their operational efficiencies but are also ensuring sustainable practices that contribute to food security.

Sustainability in Focus: Eco-Friendly Practices and Machines Transforming Rice Processing

In recent years, the agriculture sector has witnessed a commendable shift towards sustainable practices, particularly in rice processing. The integration of eco-friendly machines has significantly reduced carbon footprints and resource wastage. These advancements are not only designed to enhance efficiency but also prioritize the health of our planet. Some noteworthy innovations include:

- Solar-Powered Dryers: Harnessing the sun’s energy, these dryers minimize reliance on fossil fuels, thus lowering greenhouse gas emissions.

- Water-Conserving Technology: Machines equipped with advanced irrigation systems optimize water usage, ensuring that this precious resource is not squandered during the processing stages.

- Biodegradable Materials: Many new machines utilize biodegradable components that reduce plastic waste in the production of rice.

Moreover, several rice processing facilities are now adopting waste-to-energy technologies, converting agricultural by-products into renewable energy sources. This approach not only cuts down on waste but also powers the processing plants sustainably. A glimpse into this evolution can be captured in the following table:

| Technology | Benefits |

|---|---|

| Solar-Powered Dryers | Reduces carbon emissions and energy costs. |

| Water-Efficient Milling | Minimizes water usage, promoting conservation. |

| Biomass Energy Systems | Transforms waste into renewable energy, lowering waste impact. |

Future Trends: Anticipating Breakthroughs and Their Impact on Global Rice Production

As the agricultural landscape evolves, several trends are poised to redefine global rice production, particularly through the lens of technological advancements and sustainability. One key area of growth is precision agriculture, which integrates data analytics, drones, and IoT devices to optimize every stage of rice farming. This technology is anticipated to enhance crop yields significantly by providing real-time insights into soil health, moisture levels, and the optimal timing for planting and harvesting. Furthermore, biotechnology is making strides with the development of genetically modified rice varieties that are resilient to climate change, pests, and diseases. This innovation not only promises to secure the rice supply but also supports sustainable farming practices by reducing the need for chemical inputs.

Innovative processing techniques will also play a crucial role in streamlining rice production. The rise of smart rice milling machines that utilize AI for quality control and efficiency will revolutionize post-harvest processing. These machines can assess the quality of grain and adjust their operations in real-time, thereby minimizing waste and maximizing output. Additionally, emerging renewable energy solutions, such as solar-powered rice mills, are being tested to reduce energy costs and reliance on fossil fuels. As these advancements proliferate, they will create a more resilient infrastructure for rice production, ensuring that this staple food can meet the demands of a growing global population while simultaneously promoting environmental stewardship.

| Trend | Impact | Potential Benefits |

|---|---|---|

| Precision Agriculture | Enhances crop yields | Real-time insights, optimized resource use |

| Biotechnology | Secures rice supply | Increased resilience, reduced chemical use |

| Smart Mill Technology | Improves processing efficiency | Minimized waste, enhanced quality control |

| Renewable Energy Solutions | Reduces energy costs | Lower carbon footprint, sustainable practices |

Future Outlook

As we conclude our exploration into the transformative journey of rice processing machines, it’s clear that innovation has paved the way for significant advancements in the agricultural sector. From rudimentary methods to cutting-edge technologies, the evolution of rice processing has not only enhanced efficiency and productivity but has also reshaped the livelihoods of countless farmers around the globe.

Embracing automation and precision, the modern rice processing machine stands as a testament to human ingenuity, bridging traditional practices with contemporary demands. As we look towards the future, it is vital to remember that these machines are more than just tools; they are catalysts for change, capable of balancing the delicate interplay between sustainability and scalability.

In a world that hungers for both quality and quantity, the ongoing revolution in grain processing will continue to play a critical role in ensuring food security and supporting economies. So, as we move forward, let us remain attentive to these advancements, for they hold the promise of a more efficient, equitable, and resilient agricultural landscape. The story of rice processing is a journey still in motion, and its chapters yet to be written are ripe with possibility.