In the bustling world of agriculture, the quest for efficiency and accuracy in rice milling has led to the creation of the ultimate rice milling machine. This complete guide will delve into the intricacies of this advanced piece of machinery, exploring its features, capabilities, and benefits for the modern farming industry. Join us as we uncover the secrets behind the ultimate rice milling machine and witness how it revolutionizes the way we process this staple food crop.

Introduction to Rice Milling Machines

Rice milling machines are essential equipment in the agricultural industry, designed to remove the outer husk and bran layers of rice grains to produce polished white rice. These machines come in various sizes and capacities, ranging from small home mills to large industrial machines used in commercial rice processing plants. The ultimate rice milling machine is versatile, efficient, and easy to operate, making it the perfect choice for rice farmers and millers looking to streamline their production process.

Features of the ultimate rice milling machine include:

- High Processing Capacity: Able to process large quantities of rice grains quickly and efficiently.

- Precision Milling Technology: Ensures consistent and uniform milling results for high-quality polished rice.

- Adjustable Settings: Allows users to customize milling settings for different types of rice grains.

| Model | Capacity | Power |

|---|---|---|

| RM-1000 | 1000 kg/h | 7.5 kW |

| RM-2000 | 2000 kg/h | 15 kW |

Key Features and Components of the Ultimate Rice Milling Machine

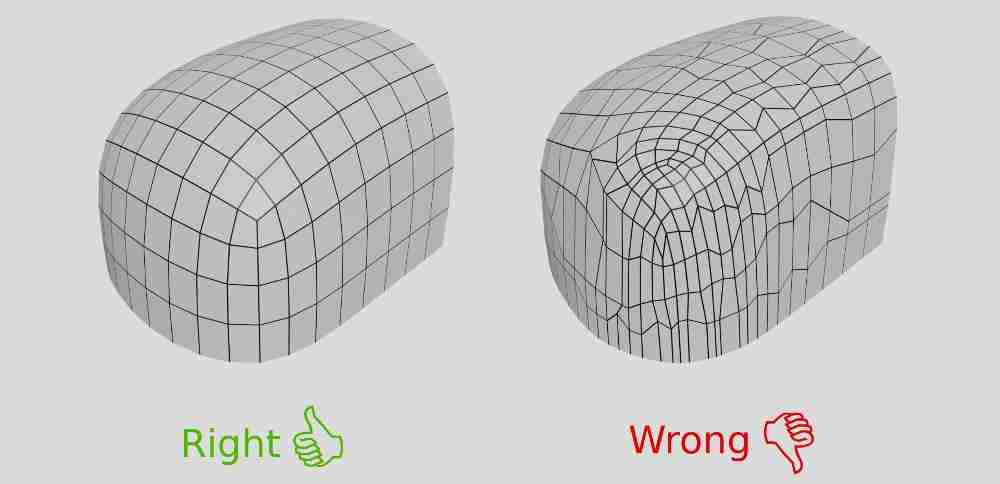

When it comes to choosing the ultimate rice milling machine, there are several key features and components to consider that can make all the difference in the efficiency and quality of your rice production. One of the most important components to look for is a high-quality milling chamber that is durable and able to efficiently process large quantities of rice. The milling chamber should be made of strong materials such as stainless steel, to ensure longevity and prevent corrosion. Additionally, look for a machine that comes equipped with a powerful motor that can handle the demands of continuous rice milling.

Another key feature to consider is the milling settings and capabilities of the machine. Look for a rice milling machine that offers customizable milling settings, such as different levels of milling precision and rice grain sizes. This will allow you to adjust the machine according to your specific rice production needs, whether you are looking to produce rice with a finer or coarser texture. Additionally, ensure that the machine is equipped with advanced technology such as automatic rice feeding and discharge systems, to streamline the milling process and increase overall efficiency.

Optimizing Efficiency and Performance: Tips for Proper Maintenance

Maintaining your rice milling machine is crucial for ensuring optimal efficiency and performance. Regular maintenance not only extends the lifespan of the machine but also helps in producing high-quality rice consistently. Here are some tips to help you properly maintain your rice milling machine:

- Clean the machine regularly: Dust and debris can accumulate in the machine, leading to decreased efficiency. Clean the machine after each use to prevent build-up and ensure smooth operation.

- Check for loose parts: Inspect the machine for any loose or damaged parts that may affect its performance. Tighten or replace any parts as needed to prevent further damage.

- Lubricate moving parts: Proper lubrication is essential for reducing friction and wear on the machine’s moving parts. Make sure to lubricate the machine regularly to keep it running smoothly.

In addition to regular maintenance, it’s essential to follow the manufacturer’s guidelines for optimal performance. By taking care of your rice milling machine, you can ensure that it continues to produce high-quality rice efficiently. Regular maintenance is the key to maximizing the machine’s efficiency and performance, so make it a priority in your operations.

| Rice Milling Machine Maintenance Checklist |

|---|

| 1. Clean the machine after each use |

| 2. Check for loose or damaged parts |

| 3. Lubricate moving parts regularly |

Choosing the Right Rice Milling Machine for Your Needs

One crucial factor to consider when is the capacity of the machine. You’ll want to assess the amount of rice you’ll need to process on a regular basis to ensure that the machine can handle the workload efficiently. Look for machines with a capacity that matches your production requirements, whether you’re a small-scale farmer or a large commercial operation.

In addition to capacity, it’s important to consider the type of rice you will be processing. Some machines are designed specifically for certain types of rice, such as long-grain or short-grain varieties. Make sure to choose a machine that is compatible with the specific type of rice you will be milling to achieve the best results. Take into account features like the milling process, polishing options, and overall performance to find the ultimate rice milling machine for your unique needs.

Concluding Remarks

In conclusion, the world of rice milling has been revolutionized by the ultimate rice milling machine. With its cutting-edge technology and efficiency, this machine has set a new standard in the industry. By following the complete guide provided here, you can maximize the potential of your rice milling operation and achieve optimum results. Remember, the key to success lies in understanding the intricacies of your machine and utilizing it to its full capacity. We hope this article has been informative and helpful in guiding you towards a successful rice milling journey. Happy milling!