In the sprawling landscapes of agricultural innovation, few advancements have garnered as much attention as the modern rice mill. Among these, the 5-ton rice mill stands out, merging traditional practices with contemporary engineering to revolutionize rice processing. As global demand for rice continues to surge, the spotlight on efficient milling technology has never been more pronounced. This article embarks on a journey to explore the myriad benefits and operational efficiencies offered by 5-ton rice mills. From enhancing output and ensuring quality to reducing labor and minimizing waste, the capabilities of these mills not only promise increased productivity but also pave the way for sustainable farming solutions. Join us as we delve into the mechanics, advantages, and transformative impact of this pivotal machinery on the rice industry.

Understanding the Core Advantages of 5 Ton Rice Mills

Investing in a 5-ton rice mill offers notable benefits that can significantly enhance production efficiency while elevating the quality of the final product. One of the primary advantages is the mill’s ability to process a substantial amount of rice daily, striking an ideal balance between productivity and energy consumption. In addition to a higher yield, modern mills are designed with advanced dehusking and milling techniques that preserve the nutritional value of the rice. This results in a superior grain, which is essential in meeting both local and export market demands.

Moreover, these rice mills often come equipped with state-of-the-art technology, including automation and precise control systems, which streamline operations and reduce the need for manual labor. This not only lowers operational costs but also minimizes the risk of human error, thereby enhancing overall consistency and quality. Key features to consider include:

- Efficiency: Maximizes output with minimal downtime.

- Durability: Built with robust materials to ensure long-lasting performance.

- Compact Design: Requires less space, making it ideal for small to medium enterprises.

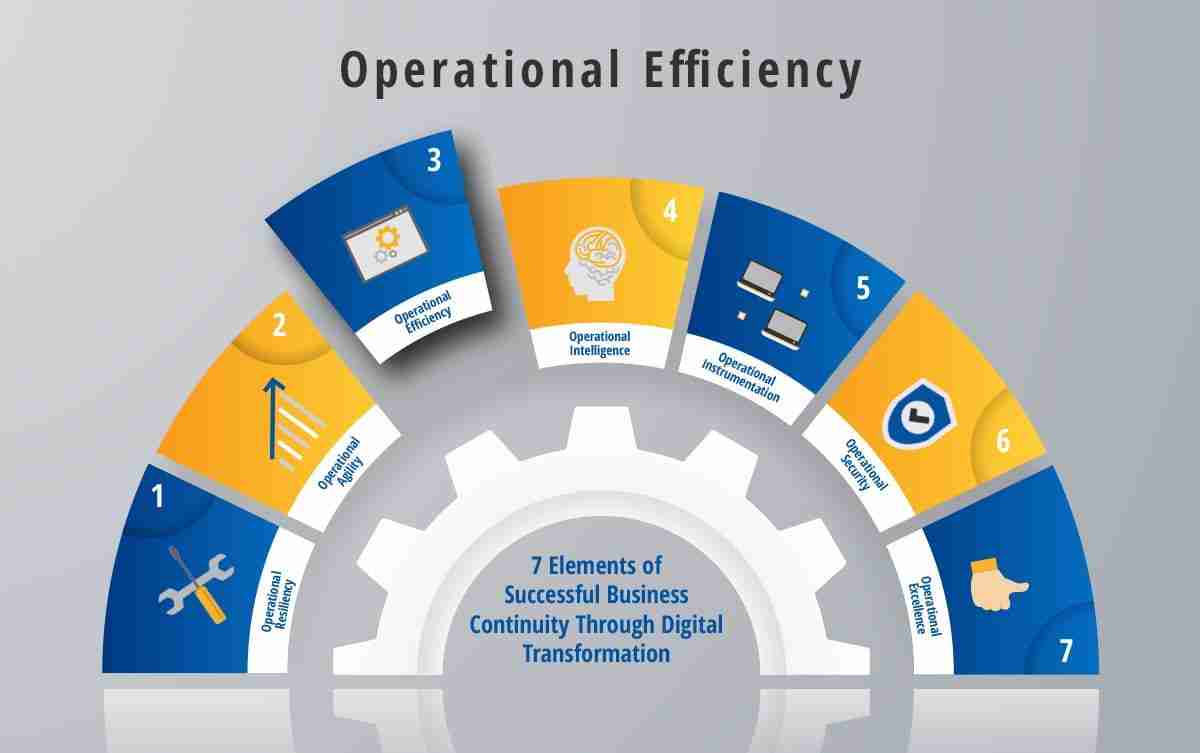

Evaluating the Operational Efficiency and Sustainability Features

In the realm of rice milling, operational efficiency is crucial not only for maximizing output but also for reducing waste and resource consumption. A 5-ton rice mill is designed to streamline processes through advanced technology, ensuring that the transformation of paddy to rice is both swift and effective. Key features contributing to this efficiency include:

- Automated Operations: By incorporating automated systems, these mills minimize human intervention, leading to consistency in production and reduced error rates.

- Energy Efficiency: State-of-the-art machinery often employs energy-saving technologies, which help in lowering operational costs and environmental impact.

- Compact Design: A smaller footprint allows for easier setup and less land use, optimizing space without compromising on production capacity.

Sustainability is a growing concern in agricultural practices, and 5-ton rice mills are designed with eco-friendliness in mind. They not only focus on output but also emphasize reducing the ecological footprint of rice processing. Some sustainability features able to achieve this include:

- Waste Management Systems: Integrated systems for managing by-products like husk and bran can be repurposed as animal feed or biofuel.

- Water Conservation: Advanced milling techniques reduce water usage during processing, preserving vital resources.

- Sourcing Local Inputs: By sourcing materials locally, these mills support sustainable farming practices and reduce transportation emissions.

| Efficiency Feature | Sustainability Benefit |

|---|---|

| Automated Operations | Consistent production with less waste |

| Energy Efficiency | Lower operational costs and reduced emissions |

| Compact Design | Optimized land use and minimal environmental disruption |

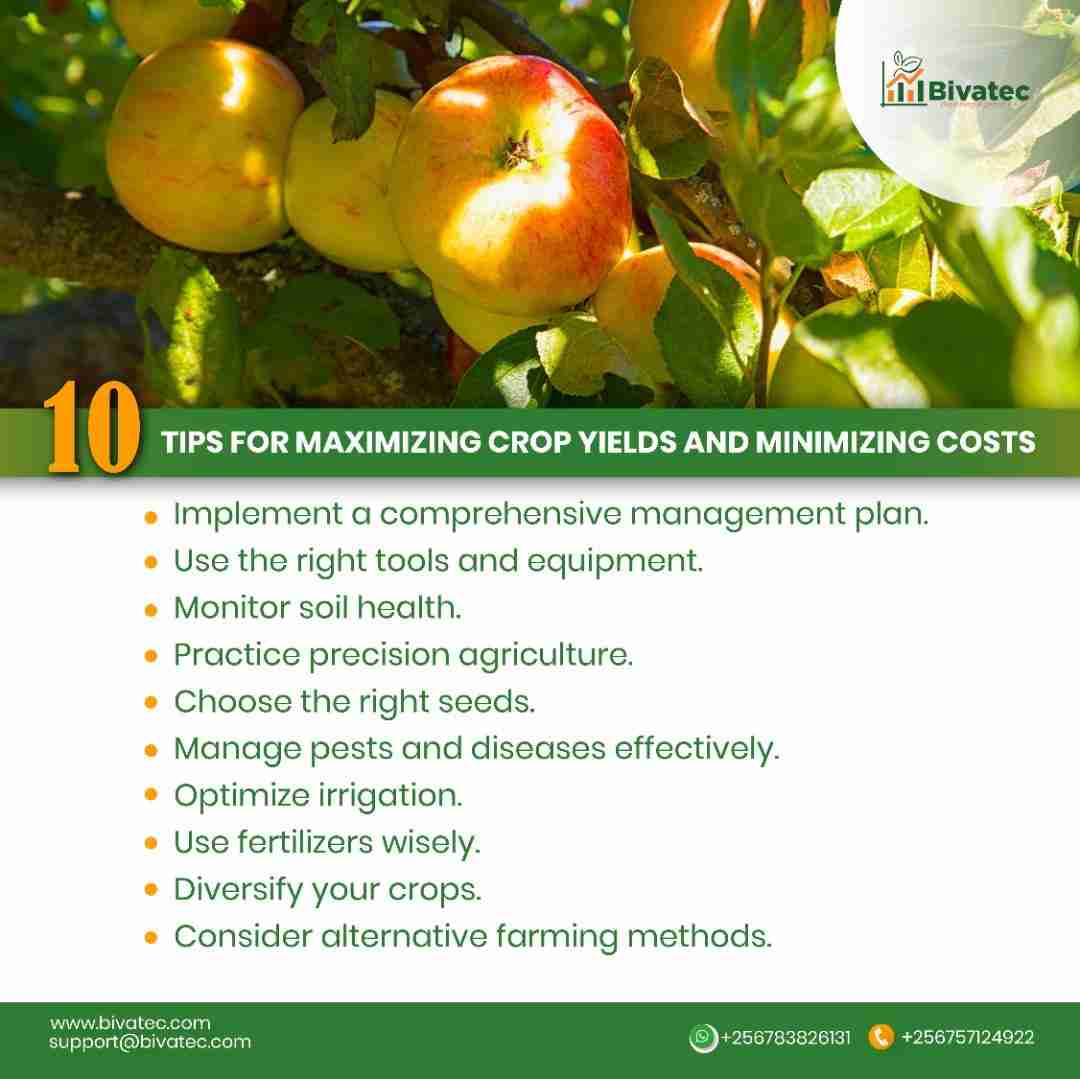

Maximizing Yield: Best Practices for Optimal Rice Processing

To achieve the highest yield from rice processing, it is essential to implement key strategies that enhance efficiency while maintaining the quality of the end product. Regular maintenance of machinery is fundamental; keeping equipment in optimal condition minimizes breakdowns and maximizes throughput. Additionally, consider the following practices:

- Invest in modern technology: Upgrading to advanced milling equipment can significantly improve processing speed and reduce grain loss.

- Optimize water usage: Implementing water recycling systems helps conserve resources and lowers operational costs.

- Monitor humidity levels: Proper storage conditions prevent spoilage and preserve rice quality, ensuring your product remains competitive.

Another vital aspect of maximizing yield is ensuring skilled labor is employed to handle the processes involved. Investing in employee training focuses on both operational techniques and safety protocols, leading to a more productive workforce. Additionally, comparing different processing methods can yield insights into cost-effectiveness. The table below illustrates a few processing methods and their characteristics:

| Processing Method | Pros | Cons |

|---|---|---|

| Traditional Milling | Lower initial cost Easy to access |

Higher labor input Lower efficiency |

| Modern Milling | High efficiency Reduced wastage |

Higher setup cost Requires skilled operation |

Investment Insights: Navigating Costs and Returns on 5 Ton Mills

Investing in a 5 ton rice mill can be a transformative decision for entrepreneurs looking to enter or expand within the agricultural sector. The initial capital outlay might seem daunting; however, a comprehensive cost-benefit analysis reveals lucrative returns that can outweigh the expenditure. Key factors influencing this investment include:

- Operational Efficiency: These mills offer high efficiency rates, resulting in faster processing times.

- Low Maintenance Costs: With robust engineering, these machines demand minimal upkeep compared to larger mills.

- Scalability: Start small and gradually increase utilization, catering to varying market demands.

To provide a clearer perspective, consider the average returns from operating a 5 ton rice mill over a typical year. The following table illustrates potential financial dynamics:

| Item | Value (Annual) |

|---|---|

| Initial Investment Cost | $50,000 |

| Annual Operating Costs | $15,000 |

| Estimated Revenue | $100,000 |

| Net Profit | $35,000 |

| Return on Investment (ROI) | 70% |

By carefully analyzing these numbers, investors can identify the potential for substantial profitability. Additionally, as the global demand for rice continues to grow, investments in processing technologies like 5 ton mills become not just viable but essential in meeting consumer needs.

To Conclude

As we draw to the conclusion of our exploration into the world of 5 ton rice mills, it becomes evident that these modern marvels are much more than mere machines; they are pivotal components in the quest for agricultural efficiency and sustainability. By harnessing advanced technology, these rice mills not only streamline the milling process but also enhance the quality of the end product, ensuring that the staple food of millions retains its nutritional value and flavor.

The benefits we’ve discussed—ranging from increased productivity to reduced waste—underscore the importance of investing in such innovations for farmers and mill operators alike. As global demands for rice continue to rise, so too does the responsibility to adopt practices that foster growth without compromising environmental integrity.

In embracing the capabilities of 5 ton rice mills, we are not just looking at immediate enhancements but also paving the way for a future in which agricultural methods are harmonized with ecological mindfulness. As we reflect on the insights gathered, it is clear that the journey of enhancement in rice milling technology is far from over. The road ahead holds immense promise, driven by innovation and a collective commitment to efficiency—ensuring that our most treasured food source is adeptly nurtured for generations to come.