Transforming Grains: A Deep Dive into Rice Mill Plants

In the heart of agricultural landscapes, where the golden fields sway in the gentle breeze, lies an essential hub of transformation—the rice mill plant. These intricate facilities stand as a bridge between harvest and plate, turning humble grains into staples that nourish millions. As we embark on this exploration, we will unravel the fascinating processes and technologies at play in rice mill plants, revealing the remarkable journey of rice from its raw state to a polished grain ready for culinary delight. Join us as we delve into the operational dynamics, the innovation driving efficiency, and the pivotal role these plants play in food security and sustainability across the globe.

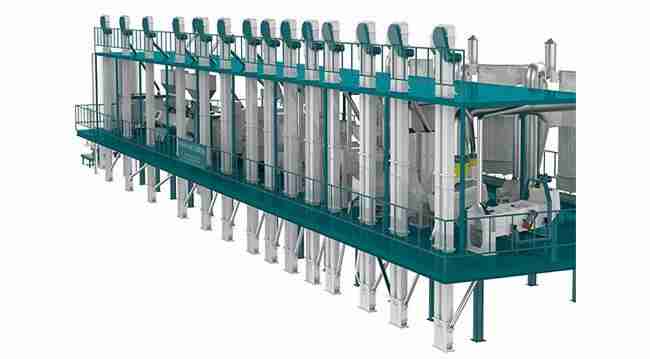

Understanding the Structure and Functionality of Rice Mill Plants

The architecture of rice mill plants is designed for efficiency, ensuring that every stage of the processing journey is executed with precision. The plant is typically divided into several distinct sections, each serving a specific function. Pre-processing, which involves cleaning and husking, is crucial for removing impurities and preparing the grain for further milling. Following this, milling transforms brown rice into white rice, separating bran and germ layers through the use of advanced machinery. The equipment used in these stages includes huskers, separators, and milling machines, all carefully calibrated to optimize performance and reduce waste.

Moreover, the functionality of a rice mill plant integrates modern technology to enhance its output. Automation plays a pivotal role in maintaining consistency and quality. Sensors and software systems monitor each processing phase, collecting data that contributes to better decision-making and efficiency. Key operational elements include:

- Drying Units: These reduce moisture content to prevent spoilage.

- Color Sorters: These ensure only the finest grains proceed to packaging.

- Packaging Systems: These facilitate efficient storage and distribution.

To provide a concise overview of the entire operation, consider the following table highlighting the core components and their functions:

| Component | Function |

|---|---|

| Husker | Removes the outer husk from grains. |

| Whitener | Polishes rice by removing bran layers. |

| Separator | Sorts different sizes and qualities of rice. |

Exploring Modern Technologies in Grain Processing

In the realm of grain processing, technological advancements are revolutionizing traditional practices, particularly in the management of rice mill plants. Today’s rice milling operations leverage state-of-the-art machinery and innovations that enhance efficiency and product quality. Key technologies include automated sorting systems that utilize machine learning algorithms for real-time decision-making, and moisture control sensors that ensure optimal storage conditions. These systems not only streamline the processing workflow but also minimize waste, resulting in a more sustainable operation.

Moreover, the integration of IoT (Internet of Things) devices enables mill operators to monitor equipment performance remotely and perform predictive maintenance. This proactive approach reduces downtime and extends the lifecycle of costly machinery. Additionally, as the market demands increased transparency, blockchain technology is being employed to track the grain supply chain from field to consumer, ensuring traceability and integrity. The following table summarizes some of the pivotal technologies currently shaping the future of rice milling:

| Technology | Benefits |

|---|---|

| Automated Sorting | Enhances quality control and efficiency |

| Moisture Sensors | Improves storage quality and reduces spoilage |

| IoT Monitoring | Facilitates remote management and predictive maintenance |

| Blockchain | Ensures supply chain transparency and trust |

Enhancing Efficiency Through Sustainable Practices

Incorporating sustainable practices into rice mill operations not only fosters environmental responsibility but also significantly enhances efficiency. By adopting an integrative approach to resource management, these plants can reduce waste and optimize output. Key strategies include:

- Water Conservation: Implementing advanced irrigation techniques and recycling wastewater can lead to substantial reductions in water usage.

- Energy Efficiency: Utilizing renewable energy sources, such as solar and biomass, alongside energy-efficient machinery helps lower operational costs.

- Sustainable Sourcing: Partnering with local farmers who practice sustainable agriculture ensures a consistent supply of high-quality grains while promoting local economies.

- Waste Recycling: Converting byproducts like husks into biofuel or organic fertilizers minimizes waste and maximizes resource utilization.

A few rice mill plants have already seen the benefits of these practices reflected in their productivity and cost savings. For example, a comparative analysis of mills operating different sustainability strategies reveals:

| Mill Type | Water Usage (liters/ton) | Energy Consumption (kWh/ton) | Waste Material Recycled (%) |

|---|---|---|---|

| Traditional | 2,500 | 200 | 10% |

| Sustainable | 1,200 | 150 | 50% |

This data illustrates the tangible advantages of transitioning to more sustainable practices, showcasing how environmentally friendly operations can lead to increased efficiencies, less resource depletion, and an overall more sustainable rice milling industry.

Navigating Market Trends and Future Opportunities in Rice Milling

Understanding the dynamics of market trends in rice milling is essential for stakeholders aiming to leverage future opportunities. With the global demand for rice projected to grow, the rice milling industry is witnessing transformative changes driven by advancements in technology and evolving consumer preferences. Efficiency and sustainability are at the forefront of these trends, prompting companies to adopt modern milling techniques and energy-efficient machinery. Businesses that adapt to these shifts will not only enhance productivity but also improve their environmental impact, which is increasingly important to consumers.

To maximize potential, stakeholders should consider focusing on the following key areas:

- Adoption of Automation: Utilizing smart technology can streamline operations and minimize human error.

- Sustainable Practices: Implementing eco-friendly milling processes can cater to the growing market of environmentally conscious consumers.

- Product Diversification: Exploring value-added products like brown rice and rice bran oil can open up new revenue streams.

- Supply Chain Optimization: Enhancing logistics and sourcing strategies to reduce costs and improve responsiveness to market demand.

| Opportunity Area | Market Impact |

|---|---|

| Automation in Mills | Increases efficiency by up to 30% |

| Eco-friendly Practices | Attracts a growing demographic of eco-conscious consumers |

| Diverse Rice Products | Diversifies income; minimizes risk |

| Logistics Improvement | Lowers operation costs significantly |

To Wrap It Up

the journey through the world of rice mill plants reveals a fascinating interplay between tradition and innovation. As we have explored, these facilities are not merely places of production but hubs of transformation where raw grains undergo meticulous processes to emerge as vital staples for countless communities around the globe. The evolution of rice milling techniques, driven by advancements in technology and a growing awareness of sustainability, highlights the industry’s responsiveness to modern challenges and consumer demands.

As we look ahead, it becomes clear that the future of rice milling will continue to be shaped by the need for efficiency, quality, and environmental stewardship. The ongoing dialogue between heritage and progress invites us to appreciate not just the end product, but the intricate systems and skilled hands that make it possible. As we savor a bowl of rice, let us remember the hidden journeys that grains undertake—from the field to the mill, and ultimately, to our tables. The world of rice mill plants is a testament to human ingenuity and the essential role these institutions play in feeding the world.