In the heart of Asia, where rice is more than just a staple food—it is a cultural emblem—efficient processing methods play a crucial role in meeting the demands of both local and global markets. Enter the 4-ton rice mill plant, a marvel of modern agricultural engineering that marries technology with tradition to elevate rice production to new heights. This article delves into the intricate workings of these compact yet powerful facilities, exploring how they streamline processes, enhance output quality, and support sustainable practices in the rice industry. As we embark on this journey through the inner mechanisms of a 4-ton rice mill plant, we invite you to discover how this innovative solution not only boosts efficiency but also ensures that the legacy of rice cultivation thrives in an ever-evolving landscape.

Maximizing Output Efficiency in a 4-Ton Rice Mill Plant

To achieve peak performance in a 4-ton rice mill plant, strategic planning and operational practices are critical. One of the most effective methods includes streamlining workflows to minimize downtime, thereby enhancing productivity. Key practices include:

- Regular Maintenance: A well-maintained mill reduces the likelihood of unexpected breakdowns, ensuring continuous operation.

- Training Operators: Skilled personnel who understand equipment settings can optimize production speed and quality.

- Inventory Management: Keeping track of raw materials and finished products helps in managing supply and demand efficiently.

Additionally, leveraging technology can significantly impact output efficiency. Automation and advanced milling machinery not only enhance precision but also allow for real-time monitoring of the production process. This results in:

| Technology Type | Impact on Efficiency |

|---|---|

| Automated Sensors | Monitor moisture levels for optimal storage conditions. |

| Energy Efficient Machines | Reduce power consumption, lowering operational costs. |

| Process Control Software | Enhances real-time adjustments for maximum output quality. |

Essential Technologies for Optimal Rice Milling Processes

To achieve high-quality rice milling, incorporating the right technologies is crucial. Key components of a modern rice mill include huskers, millers, and separator systems that work in sync to enhance efficiency. These machines are designed to optimize the milling process by minimizing broken grains and maximizing the separation of husks. Using advanced technologies, such as infrared rice sensors and automated grading systems, facilitates real-time adjustments ensuring that the milling setup operates at maximum capability. Additionally, the integration of cleaning equipment helps in removing impurities, which significantly contributes to overall product quality.

Another fundamental aspect is the implementation of energy-efficient machinery that reduces operational costs while maintaining peak performance. This includes variable frequency drives to control motor speeds and enhance energy usage. Moreover, data analytics tools can be integrated into the system to monitor the milling process, allowing for proactive maintenance and quality assurance. Below is a summary of the essential technologies in a rice mill plant:

| Technology | Function | Benefits |

|---|---|---|

| Huskers | Removes husks from brown rice | Increases yield |

| Milling Machines | Grinds and polishes rice | Improves grain appearance |

| Separator Systems | Sorts rice by quality | Enhances product quality |

| Cleaning Equipment | Eliminates impurities | Ensures food safety |

| Energy-efficient Machinery | Optimizes energy use | Reduces operational costs |

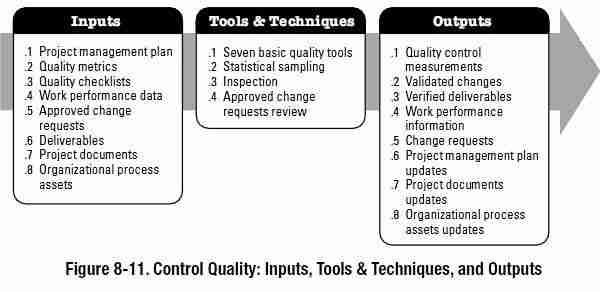

Quality Control Measures to Enhance Rice Production Standards

Implementing stringent quality control measures is pivotal in achieving high standards of rice production. By monitoring every stage of the processing system, producers can mitigate risks associated with contamination and loss of quality. Key aspects of quality control include:

- Regular Inspection: Frequent checks on equipment and processes ensure consistent operational efficiency.

- Grading of Raw Materials: Establishing strict grading criteria for paddy rice ensures that only the best quality is processed.

- Moisture Content Measurement: Maintaining optimal moisture levels helps in preventing spoilage and enhancing storage life.

Furthermore, investing in technology aids in refining quality assurance practices significantly. Incorporating systems for real-time data tracking allows mill operators to adjust processes dynamically. Essential technological upgrades include:

- Automated Sorting Systems: These systems use sensors to eliminate inferior grains before milling.

- Quality Control Software: Advanced analytics tools enable detailed monitoring of production metrics.

- Feedback Mechanisms: Gathering feedback from consumers can drive continuous improvement and innovation in production techniques.

| Quality Control Measure | Benefits |

|---|---|

| Regular Inspection | Ensures equipment operates effectively |

| Grading of Raw Materials | Guarantees high quality from the start |

| Moisture Content Measurement | Prevents spoilage during storage |

| Automated Sorting Systems | Reduces human error in sorting |

| Quality Control Software | Enhances monitoring of production efficiency |

| Feedback Mechanisms | Drives proactive improvements |

Sustainable Practices for a Profitable Rice Milling Operation

Implementing sustainable practices within a rice milling operation not only supports environmental health but also enhances profitability. By focusing on resource management, mills can significantly decrease waste and operational costs. Consider the following methods:

- Energy-Efficient Technology: Utilize energy-efficient machines and renewable energy sources, such as solar or biomass, to power milling operations.

- Water Conservation: Implement water recycling systems to minimize usage during the milling process, reducing overall costs.

- Waste Utilization: Transform by-products, like husks and bran, into valuable resources, either through animal feed or as organic fertilizers.

Maintaining a strong commitment to sustainable practices will improve not only the marketable quality of the rice but also resonate with consumers’ growing demand for eco-friendly products. Furthermore, budgeting for sustainability initiatives can yield impressive returns, especially when examining potential reductions in operational overhead. Below is a comparative table showcasing the benefits derived from adopting sustainable methods:

| Practice | Benefit |

|---|---|

| Energy-Efficient Machines | Lower Energy Costs |

| Water Recycling | Reduced Water Bills |

| Waste Management | Additional Revenue Streams |

To Conclude

the journey toward establishing a highly efficient 4-ton rice mill plant is not merely a venture into agricultural production; it is an investment in quality, sustainability, and community development. By embracing advanced technology, integrating best practices, and prioritizing operational efficiency, mill owners can enhance both the quantity and quality of their output. This approach not only satisfies the growing demands of the market but also uplifts the livelihoods of farmers and workers alike, fostering a sense of pride and ownership in the production process.

As we stand at the crossroads of innovation and tradition, the path to quality production in rice milling is paved with opportunity. With careful planning, sound investment, and a commitment to excellence, the efficient 4-ton rice mill plant can serve as a beacon of progress in the agricultural sector. Let us move forward with a vision that prioritizes not just the grains we harvest, but the hopes and aspirations we cultivate within our communities. The future of rice milling holds promise—embracing it is the first step toward a sustainable and prosperous agricultural landscape.