In a world where the quest for efficiency often meets the demands of sustainability, innovation pulses at the heart of modern agriculture. Enter the humble yet transformative mini rice polisher. Once merely a grunt of machinery in vast processing plants, these compact units are revolutionizing grain production, breathing new life into traditional methods and catering to the changing ethos of consumers. As smallholder farmers embrace this cutting-edge technology, the landscape of rice milling is undergoing a profound shift—one that promises to enhance quality, reduce waste, and empower local economies. This article delves into the rise of mini rice polishers, exploring their impact on the rice industry and how they are paving the way for a more sustainable future in grain processing.

Exploring the Evolution of Grain Processing Technology

The field of grain processing technology has undergone substantial transformations throughout history, driven by the need for efficiency and higher quality outputs. From the rudimentary hand-operated stone mills of ancient times to today’s advanced machinery, each evolution has played a crucial role in enhancing grain quality and productivity. Recently, the emergence of mini rice polishers has marked a pivotal shift in this landscape, enabling small-scale farmers and millers to achieve superior polishing results without the need for large, expensive equipment. These compact machines cater to the needs of niche markets, providing customized solutions that meet the specific demands of local consumers.

One of the most significant advantages of mini rice polishers lies in their ability to optimize the milling process while minimizing waste. Key benefits of this innovative technology include:

- Compact Design: Easy to use and transport.

- Energy Efficiency: Lower power consumption compared to traditional polishers.

- Quality Control: Enhanced texture and color of polished rice.

- Cost-Effective: Lower initial investment for small-scale operations.

With the rise of these mini machines, smallholder farmers can now compete on a global scale, ensuring that high-quality rice finds its way into various markets. By bridging the gap between artisanal and industrial milling, mini rice polishers play an instrumental role in the ongoing evolution of grain processing technology.

Understanding the Benefits of Mini Rice Polishers for Modern Farmers

Mini rice polishers are quickly becoming indispensable tools for contemporary farmers, merging technology with traditional farming practices to enhance productivity. These compact machines are designed to efficiently remove husks and polish rice, ensuring high-quality grains with minimal labor. By streamlining the rice processing workflow, farmers are able to focus their efforts on cultivation and yield management, leading to increased overall efficiency. Additionally, the portability of these machines allows them to be used in various locations, adapting easily to the agricultural landscape.

The benefits of adopting mini rice polishers extend beyond mere convenience; they also promise significant economic advantages. Consider the following benefits:

- Enhanced Grain Quality: Polished rice retains its aesthetic appeal, attracting better market prices.

- Time Efficiency: Shorter processing times mean that farmers can prepare their harvest sooner, enabling quicker sales.

- Cost-Effectiveness: Lower energy consumption reduces operational costs, making farming more sustainable.

- Simplicity of Use: Designed with user-friendly controls, these machines are easy to operate, even for those without extensive training.

To illustrate these advantages further, consider the following comparative overview:

| Traditional Processing | Mini Rice Polisher |

|---|---|

| Labor-Intensive | Semi-Automated |

| Higher Energy Costs | Lower Energy Consumption |

| Long Processing Times | Quick Turnaround |

| Variable Grain Quality | Consistent High Quality |

This shift towards mini rice polishers not only supports local economies but also paves the way for environmentally friendly practices, as farmers move away from outdated methods. As these technologies become more accessible, the agricultural landscape promises a revolution in how rice is processed, traded, and appreciated worldwide.

Maximizing Efficiency: Best Practices for Implementing Mini Rice Polishers

Incorporating mini rice polishers into your grain processing operations can significantly enhance productivity and product quality. To maximize their efficiency and ensure smooth integration, consider the following best practices:

- Assessment of Grain Quality: Before polishing, evaluate the quality of the rice to determine the optimal settings for the polisher.

- Regular Maintenance: Implement a strict maintenance schedule to keep the machinery in top condition. Regular cleaning and parts inspection can prevent breakdowns and delays.

- Operator Training: Invest in comprehensive training sessions for your operators to ensure they understand the machinery and can troubleshoot minor issues.

- Batch Processing: Optimize the batch size when using the polishers to maximize output without compromising quality.

Tracking performance metrics is essential for ongoing refinement and innovation. Using analytics can provide valuable insights into processing times, output quality, and areas for improvement. Create a performance evaluation table to assess key statistics:

| Metric | Target Value | Current Value | Comments |

|---|---|---|---|

| Processing Time (hrs) | 3 | 2.5 | On track |

| Output Quality (%) | 95 | 92 | Minor adjustments needed |

| Downtime (hrs) | 0.5 | 0.3 | Excellent |

By adhering to these practices, processors can effectively utilize mini rice polishers, leading to enhanced operational efficiency and quality outcomes in grain processing.

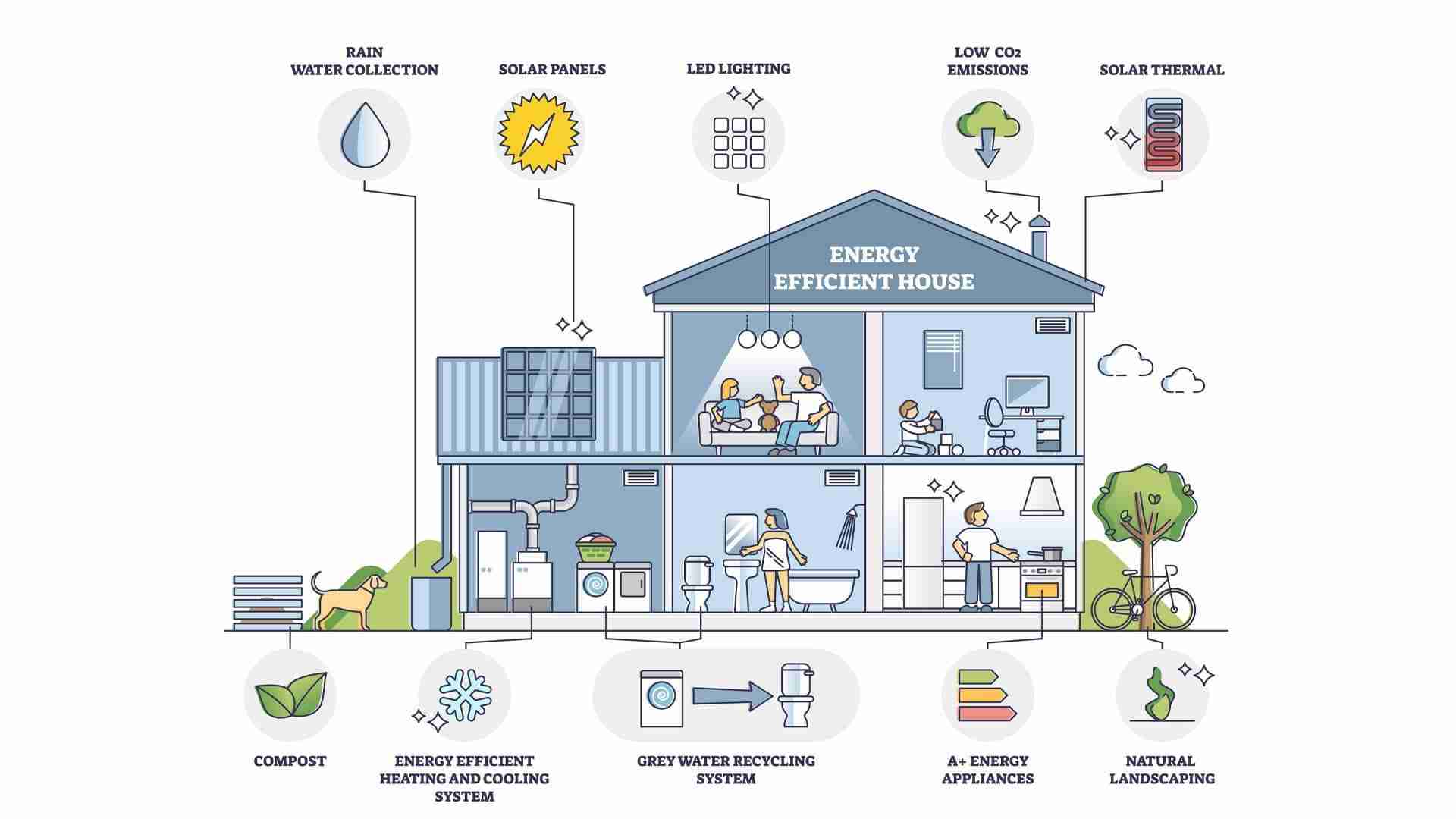

Sustainability in Grain Production: The Role of Mini Rice Polishers in Eco-Friendly Practices

As the demand for sustainable agricultural practices intensifies, technologies that enhance productivity while minimizing environmental impact are gaining traction. Mini rice polishers exemplify this shift towards eco-friendly grain production. Their compact design not only optimizes the polishing process but also significantly reduces energy consumption compared to traditional, larger machines. This efficiency translates into lower carbon emissions during operation, aligning grain production with broader sustainability goals. Furthermore, the reduction in waste achieved through precise polishing ensures that more of the grain is utilized, maximizing the output of each harvest.

These innovations help in preserving the nutritional integrity of rice, which is crucial for food security. By employing mini rice polishers, farmers can achieve a balance between quality and quantity. The polished rice retains important vitamins and minerals, thereby providing healthier food options for consumers. The adoption of these machines can enhance local economies, as they are often produced and maintained within the community, supporting sustainable job creation. As the agrarian landscape transforms, mini rice polishers are proving to be a vital tool for farmers aiming to embrace environmentally responsible practices.

The Conclusion

As we navigate the ever-evolving landscape of agriculture and food production, the emergence of mini rice polishers signals a promising shift towards greater efficiency and quality in grain processing. By streamlining operations and enhancing the end product, these innovative machines are not just a testament to technological advancement but also a catalyst for empowering farmers and improving livelihoods. The rise of mini rice polishers represents more than just a trend; it embodies a commitment to sustainability and a deeper understanding of the intricate relationship we share with our food. As we look to the future, it is clear that the revolution in grain processing is just beginning, paving the way for continued innovation that prioritizes both productivity and quality. In this new era, the humble rice grain finds itself at the forefront of a transformative journey—one that echoes the age-old quest for betterment in our agricultural practices. The tale of mini rice polishers is only just starting to unfold, inviting us all to stay tuned to see how this small-scale change can leave a lasting impact on our plates and beyond.