Transforming Grains: The Journey of a Paddy Processing Plant

In the heart of lush green fields, where the sun kisses the earth and monsoon rains bring life, lies a story waiting to be told—the transformative journey of paddy grains. From the delicate stems swaying in the wind to the bustling energy of a processing plant, this narrative unfolds at the intersection of tradition and innovation. Each grain, a testament to the hard work of farmers, embarks on a journey that alters its form and function, entering a realm where it becomes a staple of our kitchens and cultures.

In this exploration, we delve into a paddy processing plant, where technology meets craftsmanship. We take you behind the scenes to witness the meticulous processes that elevate raw paddy into polished rice, revealing the intricate balance between human skill and mechanized efficiency. Join us as we trace the pathways of grains, uncovering the challenges and triumphs faced along the way, and celebrate the journey that nourishes millions, one grain at a time.

Exploring the Essential Steps in Paddy Processing

Paddy processing is a meticulous journey that begins with the careful collection of harvested grains. From the paddy field to the processing plant, ensuring the grains are handled with care is crucial to maintain quality. The first essential step in this transformative journey is the cleaning of raw paddy to remove impurities such as soil, stones, and unwanted seeds. This is typically achieved through a combination of mechanical cleaning and air blowing techniques, creating a clean base for further processing. Following this, the grains undergo drying, which is vital to prevent spoilage and enhance storage longevity. Proper moisture management not only ensures quality but also boosts the subsequent milling efficiency.

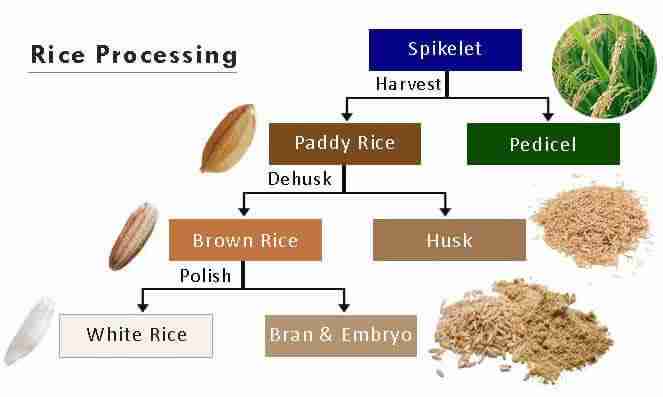

Once adequately dried, the paddy transitions into the milling phase, where the outer husk is removed to yield brown rice. At this juncture, hulling machines perform the critical task of separating the rice grain from its hull, which is discarded as waste. The next stage is polishing, where brown rice is further refined through frictional processes to achieve white rice, enhancing its appearance and texture. During this phase, a series of grading and sorting processes follow to ensure uniformity in size and quality. The final outcome is a product that is ready for packaging, distribution, and ultimately, consumer enjoyment. Here’s a simplified overview of these steps in a table format:

| Processing Step | Description |

|---|---|

| Cleaning | Removes impurities for quality assurance. |

| Drying | Prevents spoilage and enhances storage. |

| Milling | Separates the hull from the rice grain. |

| Polishing | Enhances appearance and texture of rice. |

| Grading & Sorting | Ensures uniformity in size and quality. |

Innovative Technologies Revolutionizing Grain Transformation

In the dynamic landscape of grain processing, cutting-edge technologies are paving the way for efficiency and sustainability. Advanced automation systems now dominate paddy processing plants, drastically reducing human error and labor costs. Robotic sorting and AI-driven analytics are streamlining operations, allowing for real-time quality assessments and minimizing waste. These innovations not only enhance productivity but also contribute to more precise grading—ensuring that only the finest grains reach the market. Additionally, IoT sensors play a crucial role in monitoring the supply chain, providing essential data insights that help optimize inventory management.

The integration of renewable energy solutions further underscores the transformation of paddy processing facilities. Many plants are now harnessing solar power and biogas from agricultural waste to operate machinery, thereby reducing their carbon footprint. Innovations such as water-efficient milling techniques and closed-loop hydroponic systems are revolutionizing the way grains are processed. This synergy between technology and environmental stewardship promotes sustainable practices while maintaining high production standards. In this era of innovation, the commitment to blending technology with traditional methods is reshaping the future of grain processing.

Sustainable Practices for a Greener Processing Plant

In the quest for eco-friendly operations, paddy processing plants are increasingly embracing innovative techniques that minimize environmental impact while maintaining efficiency. One of the cornerstones of a greener facility is the implementation of energy-saving technologies. This includes utilizing solar panels for power generation, which reduces reliance on fossil fuels. Additionally, the strategic use of energy-efficient machinery not only lowers electricity consumption but also enhances workflow productivity. Other sustainable practices involve the adoption of waste reduction techniques, such as:

- Recycling water used during processing to irrigate nearby crops.

- Implementing a closed-loop system for waste materials, converting them into biofuel.

- Employing natural pest control methods to minimize chemical usage.

Beyond operational efficiencies, investing in sustainable relationships with the surrounding community fosters long-term environmental stewardship. Establishing partnerships with local farmers helps ensure a steady supply of organic raw materials while promoting biodiversity. Additionally, engaging in community education programs emphasizes the importance of sustainability, such as the use of environment-friendly farming practices. This holistic approach not only benefits the plant but also cultivates a culture of sustainability within the region. The impact of these efforts can be encapsulated in the following table:

| Initiative | Benefit |

|---|---|

| Energy-efficient machinery | Reduced operational costs |

| Water recycling | Conservation of resources |

| Natural pest control | Healthier ecosystems |

Maximizing Efficiency: Strategies for Enhanced Production

Improving output in a paddy processing plant is a multifaceted endeavor that requires an amalgamation of technology and process optimization. One essential approach is the integration of automated systems, which can dramatically reduce manual labor and its associated errors. By implementing advanced machinery, plants can enhance accuracy in activities such as husking and polishing. Embracing technology like sensors for real-time monitoring not only allows for quality control but also aids in predictive maintenance, which can minimize downtime. Furthermore, streamlining workflows through lean manufacturing principles ensures that each step in the processing line is both efficient and waste-conscious, leading to a more sustainable operation.

To foster a culture of continuous improvement, regular employee training and involvement in decision-making processes are paramount. Empowering staff with knowledge enables them to identify inefficiencies and contribute to innovative solutions. Consider implementing a feedback loop system where suggestions for improvements are collected and rewarded. Additionally, fostering collaboration with local farmers can establish a solid supply chain, ensuring that the raw materials are both fresh and of high quality. This synergistic approach not only enhances production capabilities but also nurtures community relations, ultimately resulting in better product outcomes and increased market competition.

To Conclude

In the heart of every bustling paddy processing plant lies a world where raw grains undergo a remarkable transformation, turning from humble seeds into vital staples that nourish communities. As we’ve traced the intricate journey of these grains—from harvest through the complex machinery and processes that refine them—it’s clear that this industry is more than a series of mechanical operations; it is a testament to human ingenuity and a commitment to feeding the future.

The story of paddy processing is not just about the grains themselves, but also about the people who dedicate their lives to this essential work. Their expertise and passion ensure that every bag of rice carries with it a legacy of care and craftsmanship, echoing through generations. As we reflect on this journey, we are reminded of the interconnectedness of agriculture, technology, and sustainability.

The transformation of grains is an ongoing dialogue between tradition and innovation, one that will continue to evolve as we face the challenges of feeding a growing global population. By understanding the delicate balance of these processes, we appreciate not just the food on our plates but the entire ecosystem that makes it possible.

As we conclude our exploration, let us carry forward the knowledge of this journey—embracing the stories behind the grains we consume and recognizing the vital role that paddy processing plays in sustaining our world. In every bite, there lies a rich narrative waiting to be savored.