Title: Transforming Grain: The Journey Inside a Modern Rice Mill

In the heart of agricultural innovation, where tradition meets technology, lies a dynamic world often overlooked—the modern rice mill. As an essential link in the food supply chain, rice mills have evolved into sophisticated facilities that transform harvested grains into the staple we find on our dinner tables. This article embarks on a captivating journey inside these mechanized hubs, delving into the intricate processes that convert paddy rice into polished grains. From the rhythmic hum of machinery to the careful balancing of tradition and modern efficiency, we will explore the crucial steps that ensure quality, sustainability, and traceability in rice production. Join us as we unveil the transformative journey of grain, shedding light on the remarkable systems and dedicated individuals that fuel this vital industry.

The Evolution of Milling Technology and Its Impact on Grain Quality

The journey of milling technology showcases an extraordinary transition from rudimentary practices to sophisticated processes that enhance grain quality significantly. Early milling methods relied on simple tools such as mortar and pestle, which offered limited precision and efficiency. As industrialization took hold, the introduction of mechanized milling revolutionized the grain processing landscape. Hydraulic and steam-powered mills represented a significant advancement, allowing for mass production and greater control over the milling process. These innovations not only increased yield but also began to focus on preserving the quality of the grain. Today, advanced technologies like satellite imaging, AI algorithms, and automated monitoring systems elevate the standards of milling, ensuring that grains are milled with minimal damage and optimal milling rates.

Modern rice mills, equipped with cutting-edge technology, utilize a combination of mechanical and digital tools to achieve unparalleled grain quality. The incorporation of hydrothermal treatment, air classification, and stone milling techniques allow for tailored processing methods, resulting in cleaner, more nutritious end products. A typical milling line may include stages such as:

- Pre-cleaning: Removal of foreign materials.

- Hulling: Separation of the husk from brown rice.

- Whitening: Polishing rice grains to remove bran layers.

- Grading: Sorting based on size and quality.

The impact of these advancements on grain quality is profound, as they not only enhance the aesthetic appeal and shelf life but also preserve essential nutrients and flavors that are often lost in traditional milling processes. Below is a comparison table illustrating some notable differences in quality metrics before and after the introduction of modern milling techniques:

| Quality Metric | Traditional Milling | Modern Milling |

|---|---|---|

| Grain Breakage Rate | 15-20% | 5-10% |

| Nutrient Retention | Varies | High |

| Flavor Profile | Limited | Enhanced |

The ongoing evolution of milling technology signifies a commitment to improving grain quality while meeting the demands of a growing population. As these processes continue to advance, the benefits will stretch beyond just aesthetics, ultimately contributing to improved food security and nutrition for consumers worldwide.

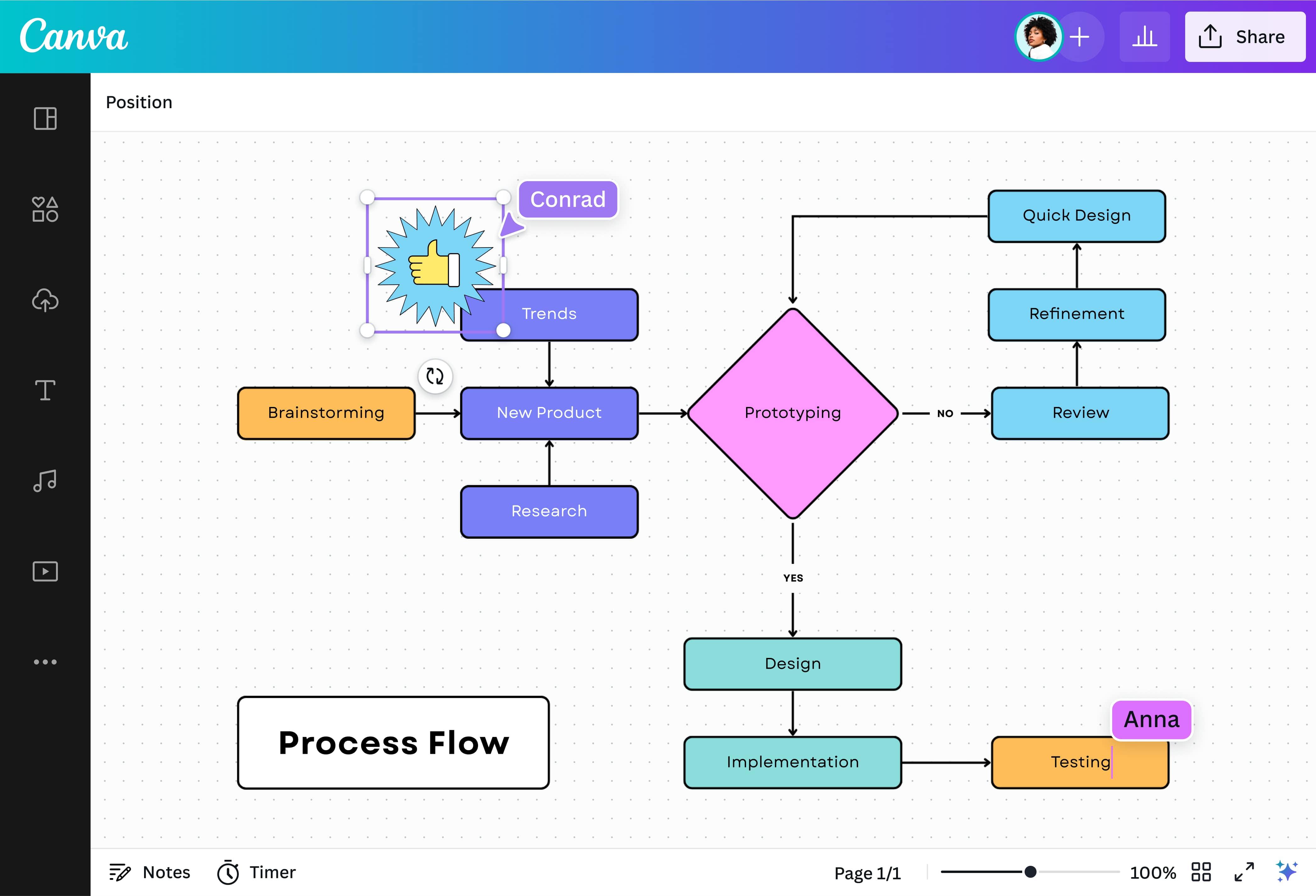

Exploring the Process Flow: From Paddy to Polished Rice

The transformation of paddy into polished rice is a fascinating journey filled with intricate steps that harness both technology and tradition. Initially, the harvested paddy goes through a critical phase known as pre-cleaning, where foreign materials like stones and straw are removed. This ensures that the grains are pure and ready for further processing. Following this, the paddy is subjected to soaking—a crucial step where the grains absorb water to prepare them for stable milling. The soaking period varies but is essential for achieving optimal quality in the final product. After soaking, the paddy enters the hulling stage, where outer husks are removed, marking the transition from raw to semi-processed rice.

The semi-processed rice, or brown rice, undergoes a meticulous milling process that grinds the grains to remove the bran layer, thus producing white rice. This stage utilizes advanced machines equipped with precision settings, ensuring that the grains retain maximum quality. Post-milling, the rice goes through polishing, which enhances its appearance and improves its cooking properties. In some cases, additional stages such as grading and packaging follow, where the rice is sorted based on quality and packaged for distribution. The entire process ensures that each grain of rice reaches consumers as a product of sophisticated engineering combined with age-old agricultural practices.

Sustainability Practices in Modern Rice Milling

In the quest for efficient grain processing, modern rice milling systems have embraced sustainability practices as an integral part of their operations. By implementing energy-efficient machinery, rice mills are significantly reducing their overall carbon footprint. These mills prioritize renewable energy sources such as solar and wind, allowing them to harness nature’s power while minimizing reliance on fossil fuels. Alongside energy savings, water management is also a focal point. Advanced filtration and recycling systems ensure that water is used judiciously, with only the necessary amounts needed for processing while maintaining stringent quality standards. This commitment not only conserves vital water resources but also contributes to a healthier environment.

Moreover, waste management in rice milling is undergoing a transformative shift. Mills are adopting zero-waste initiatives that repurpose by-products of rice milling, such as husks and bran. These materials find new life as boiler fuel, organic fertilizers, or even packaging materials, proving that nothing goes to waste in a sustainable operation. The table below illustrates the innovative uses of rice milling by-products:

| By-Product | Innovative Use |

|---|---|

| Rice Husks | Biomass fuel for energy generation |

| Rice Bran | Health supplements and animal feed |

| Broken Rice | Food products and value-added processing |

Rice mills are not just processing plants; they are evolving into models of eco-friendly innovation, showcasing how high-tech methods and environmentally conscious practices can work hand-in-hand to support both agriculture and the planet. The embrace of sustainability ensures long-term viability for rice milling, allowing mills to thrive while contributing to a more sustainable future.

Enhancing Efficiency: Automation and Smart Solutions in Grain Processing

In the contemporary landscape of grain processing, automation plays a pivotal role in ensuring consistent quality and operational efficiency. Advanced technologies such as computerized sorting systems utilize high-definition cameras and sensors to detect and remove impurities, ensuring that only the best grains proceed to the next stage. This level of precision not only improves the quality of the end product but also minimizes waste, enhancing the overall yield. Furthermore, automated control systems manage the flow of grain through multiple stages of processing, significantly reducing manual intervention, which leads to a more streamlined operation.

Smart solutions also extend to data analytics, where mills are equipped with software that monitors operational parameters in real time. This data-driven approach enables mill operators to make informed decisions, adjusting processes to optimize for speed and efficiency. By employing predictive maintenance, mills can foresee equipment failures and perform timely maintenance, reducing downtime and ensuring smooth operations. The integration of IoT devices allows for connected machinery, enabling seamless communication across the production line. The result is a holistic approach to grain processing, transforming challenges into opportunities for innovation.

In Conclusion

As we conclude our exploration of the intricate world of rice milling, it becomes clear that the journey of grain transcends mere processing; it is a harmonious blend of tradition and technology. Within the walls of a modern rice mill, every stage is a testament to human ingenuity, where age-old techniques meet cutting-edge machinery to transform simple grains into essential sustenance.

In this age of innovation, the rice mill stands as a microcosm of industry, reflecting broader trends in agricultural advancements and sustainability. The journey from paddy to polished grain is not just about efficiency; it also speaks to the deep-rooted connection between our food sources and the communities that cultivate them.

As we savor each grain on our plate, let us remember the journey it took — a pilgrimage through time, nature, and technology. The modern rice mill is not merely a facility; it is an emblem of progress, echoing the stories of farmers and millers alike, who together contribute to the global tapestry of nourishment. In a world where food security remains paramount, understanding and appreciating this journey is more important than ever.