In a world where culinary traditions meet modern technology, the journey of rice from paddies to plate is an intricate dance of precision and care. As one of the most consumed staples globally, rice is more than just food; it is a cultural cornerstone, a source of sustenance, and an agricultural cornerstone. However, the quality of rice that we eventually savor hinges significantly on the processing equipment employed in its journey. From husking and milling to polishing and packaging, each step plays a vital role in enhancing the grain’s flavor, texture, and nutritional value. In this essential guide, we will delve into the myriad of rice processing equipment available, unveiling the innovations and techniques that elevate rice quality to new heights. Whether you are a farmer looking to invest in efficiency, a mill owner seeking to enhance production, or a culinary enthusiast passionate about the perfect grain, this article serves as your roadmap to unlocking the secrets of quality rice processing. Join us as we explore the vital components of this remarkable industry and discover how technology and tradition intertwine to bring the world’s favorite grain to our tables with optimal quality.

Understanding Rice Processing Equipment: Key Technologies and Their Functions

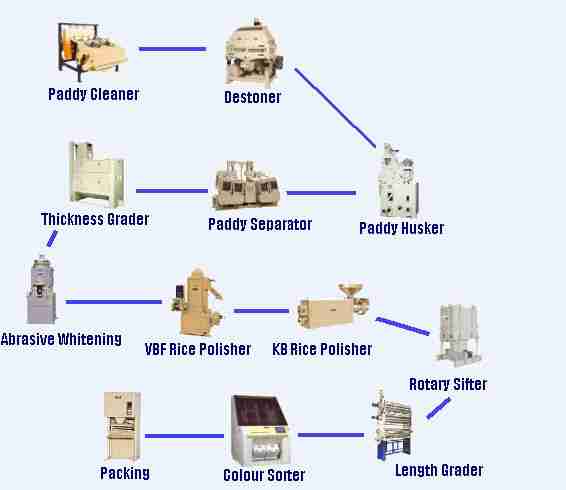

Rice processing equipment comprises a variety of innovative technologies aimed at transforming raw rice paddy into consumable rice. Each machine serves a specific purpose, ensuring that the grain is hulled, milled, and polished to meet quality standards. Color sorters utilize optical sensors to detect and eliminate discolored or damaged grains, enhancing the appearance and quality of the final product. Similarly, de-stoners remove stones and impurities, contributing to food safety and reducing wear on downstream machinery. Other pivotal machines include rice hullers, which efficiently remove inedible husks from paddy, and whitening machines, crucial for achieving a polished and uniform grain finish.

The interconnectedness of these machines creates a streamlined workflow that optimizes performance and quality. For instance, dryers ensure that the moisture content is adequately controlled, preventing spoilage during long storage periods. Understanding the interplay of these technologies is essential for both manufacturers and consumers. Here is a brief overview of additional key equipment commonly used in rice processing:

| Equipment | Function |

|---|---|

| Separator | Separates various sizes and grades of rice for uniformity. |

| Polisher | Removes remaining bran layers, enhancing gloss and refinement. |

| Packaging machines | Automates the packing process, ensuring efficiency and hygiene. |

Maximizing Efficiency: Best Practices for Optimal Rice Processing Operations

Achieving optimal rice processing operations hinges on implementing best practices that enhance efficiency while maintaining product quality. Start by adopting a workflow analysis to identify bottlenecks in the processing line. This involves assessing each stage, from milling to packaging, and ensuring that equipment is well-maintained and calibrated. Regular maintenance checks not only prolong machine life but also prevent unexpected breakdowns that can slow down operations. Consider scheduling preventive maintenance during off-peak hours to minimize disruptions to your workflow.

Incorporate automation technologies that streamline operations and reduce manual labor. Using smart sensors and machine learning can help monitor production in real time, leading to quicker adjustments and improved output consistency. Furthermore, investing in versatile multi-functional machines can cut down on the need for multiple pieces of equipment, thereby saving both space and costs. Implementation of training programs for workers is equally vital; well-informed employees will enhance operational efficiency through better handling and management of the processing equipment.

Quality Control Measures: Ensuring Consistency and Safety in Rice Production

Quality control is the backbone of the rice production process, ensuring that every grain meets high standards of consistency and safety. By implementing rigorous testing protocols and maintaining strict adherence to best practices, producers can safeguard the integrity of their product. Key components of an effective quality control system in rice processing include:

- Raw Material Inspection: Scrutinizing incoming rice for impurities and grain quality.

- In-Process Monitoring: Employing real-time assessments during processing to identify and rectify issues immediately.

- Final Product Testing: Conducting comprehensive tests for moisture content, texture, and taste before packaging.

- Traceability Systems: Establishing records that track rice from field to fork, ensuring transparency and accountability.

Utilizing modern technology enhances these quality control measures, enabling producers to detect potential defects more efficiently. Automated systems can streamline the inspection process, utilizing sensors and data analytics to provide insights into production quality. A comparison of traditional versus automated inspection methods reveals significant advantages:

| Method | Advantages | Disadvantages |

|---|---|---|

| Traditional Inspection | Lower upfront costs, human expertise | Time-consuming, subject to human error |

| Automated Inspection | Faster, more accurate, consistent results | Higher initial investment, reliance on technology |

This comparative analysis underscores the necessity of integrating technology into the quality control framework, ensuring not just compliance with industry standards but also enhancing the overall quality of rice production.

Investing Wisely: A Comprehensive Guide to Choosing the Right Equipment for Your Needs

When venturing into the world of rice processing, selecting the right equipment can significantly influence both productivity and product quality. Understanding your specific needs is essential before making any purchase. Consider factors like the scale of your operation, the types of rice you plan to process, and the level of automation you desire. Key aspects to evaluate include:

- Capacity: Choose machines that align with your processing volume.

- Efficiency: Opt for equipment that maximizes output while minimizing resource usage.

- Maintenance: Select machines that are easy to maintain and service.

- Technology: Look for advanced features that enhance precision and consistency.

- Cost-effectiveness: Evaluate the total cost of ownership, not just purchase price.

Another vital consideration is the vendor’s reputation and the support they provide. Researching the manufacturer’s background can offer insight into their customer service and the reliability of their equipment. It’s also beneficial to read reviews and ask other processors about their experiences. When comparing options, creating a table can help visualize different manufacturers and their offerings:

| Manufacturer | Type of Equipment | Support Services |

|---|---|---|

| RiceTech | Automated Milling | 24/7 Customer Support |

| GrainPro | Storage Solutions | On-Site Training |

| HarvestWorks | Drying Systems | Installation Assistance |

Ultimately, the investment you make in rice processing equipment will not only determine your operational efficiency but will also impact the quality of your final product. Assessing your needs and thoroughly researching equipment options can lead to informed decisions that will foster long-term success in your rice processing endeavors.

Final Thoughts

As we draw the curtains on our exploration of rice processing equipment, it is clear that the journey from paddy to plate is not just a physical transformation but a delicate art that hinges on quality. By unlocking the potential of advanced machinery and innovative techniques, we can ensure that every grain of rice maintains its nutritional value, flavor, and texture.

This guide has provided you with insights into the essential tools and technologies that enhance rice processing, emphasizing the importance of investment in quality equipment. Whether you are a farmer seeking to optimize your harvest or a business owner aiming to elevate your production standards, understanding the nuances of rice processing can empower you to make informed decisions that resonate throughout the industry.

As we look to the future, let us commit to nurturing the integrity of this staple food. With the right equipment and a focus on quality, we can elevate rice processing standards, safeguard our food systems, and fulfill the needs of consumers around the globe. Here’s to a future where every meal benefits from the attentive art of rice processing, unlocking the quality that lies within each grain.