In the heart of agricultural innovation, efficiency is not just a metric; it’s a necessity. As the world grapples with the demands of an ever-increasing population and the need for sustainable food production, the tools we utilize to process our staple crops are more critical than ever. Enter the 5-ton rice mill—a marvel of engineering designed to transform the raw potential of paddy rice into polished grains with remarkable speed and precision. This article delves into the transformative power of this machine, exploring how it enhances productivity, minimizes resource wastage, and empowers local farmers to meet the challenges of modern agriculture. Join us as we unpack the intricacies of rice milling and unveil the significant impact a 5-ton rice mill can have on efficiency and food security.

Exploring the Technological Advancements in 5-Ton Rice Mills

In recent years, the rice milling industry has undergone a significant transformation with the advent of advanced technology that has dramatically improved the efficiency and output of 5-ton rice mills. Key innovations have redefined the processing stages, making them faster and more precise. Modern rice mills now integrate state-of-the-art machinery featuring automated grading systems, vibration-less hulling machines, and smart monitoring tools that collectively enhance productivity. These technological advancements ensure minimal wastage and optimal output, fundamentally changing the landscape of rice production.

Moreover, the incorporation of data analytics into the daily operations of rice mills enables millers to make informed decisions based on real-time data. This proactive approach results in improved quality control and better resource management. For instance, technology-driven solutions allow for meticulous tracking of moisture levels, essential for maintaining grain quality. Other benefits include:

- Energy Efficiency: Enhanced machines consume less power.

- Labor Savings: Automation reduces the need for manual intervention.

- User-Friendly Interfaces: Simplified operations allow for easy training of staff.

To illustrate the impact of these advancements, consider the following table that compares traditional and modern 5-ton rice mills in terms of key performance indicators:

| Feature | Traditional Mills | Modern Mills |

|---|---|---|

| Processing Speed | 4-5 tons per day | 10 tons per day |

| Power Consumption | High | Reduced |

| Waste Generation | 15% | 5% |

This data clearly demonstrates how the infusion of technology not only boosts operational capabilities but also aligns with sustainable practices, making modern rice mills more appealing to forward-thinking entrepreneurs in the agricultural sector.

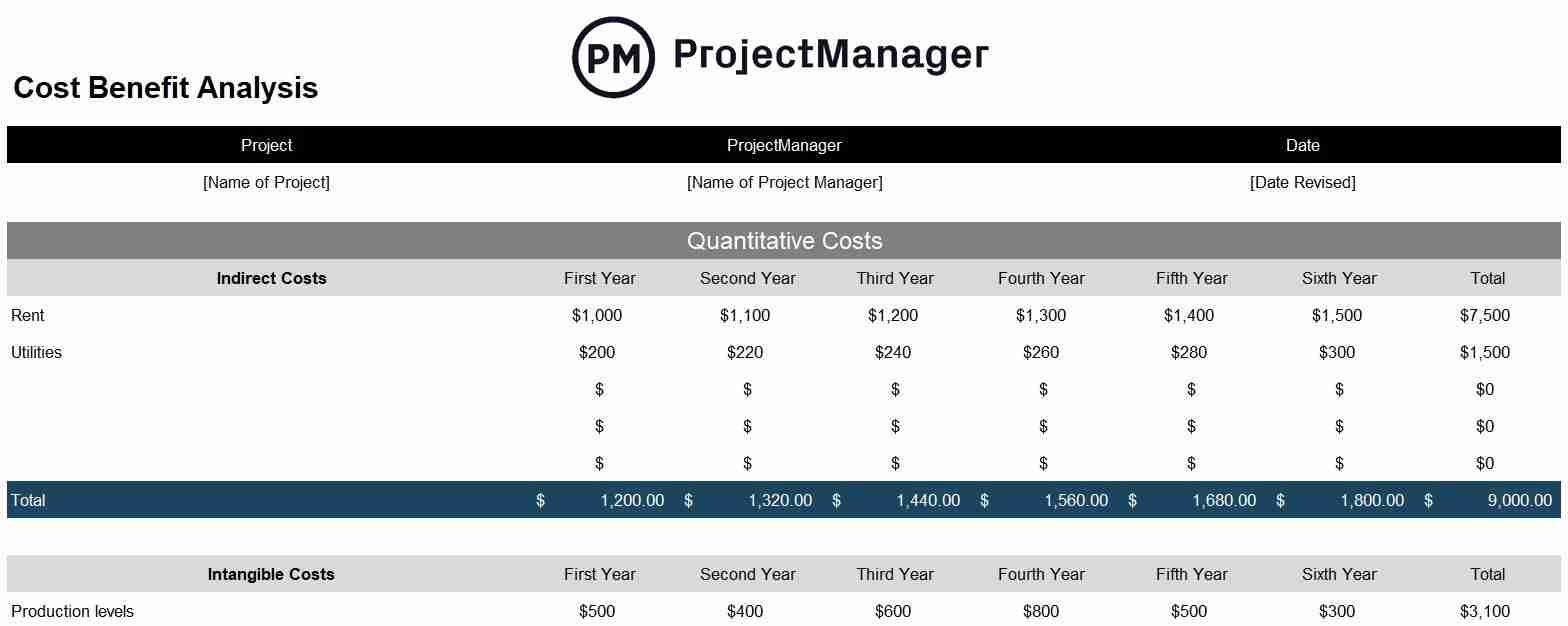

Understanding the Cost-Benefit Analysis of Rice Milling Operations

In assessing the efficiency of rice milling operations, a thorough evaluation of costs and benefits is crucial. This analysis encompasses a variety of factors, each contributing uniquely to the overall profitability of the venture. Key elements to consider include:

- Initial Investment: The upfront cost of purchasing and installing a 5-ton rice mill can be substantial, but it is an essential step in ensuring a sustainable operation.

- Operational Costs: These consist of maintenance, labor, utilities, and raw materials, all of which directly impact the bottom line.

- Market Demand: Understanding the demand for milled rice in your target market helps inform pricing strategies and potential revenue.

- Technological Efficiency: Enhanced machinery can reduce time and labor costs, improving the overall throughput of the milling process.

Alongside costs, the benefits encompass both tangible and intangible returns. The potential for increased output leads to greater sales volumes, while customer satisfaction can be bolstered through consistent quality. Moreover, a properly executed milling operation contributes to local economies by:

| Benefit | Description |

|---|---|

| Employment Opportunities | Creates jobs through direct staffing and supports local suppliers. |

| Quality Assurance | Ensure high-grade rice production enhances the brand’s reputation. |

| Community Development | Supports local infrastructure projects through economic contributions. |

Ultimately, a careful cost-benefit analysis not only highlights the financial viability of rice milling operations but also showcases their broader social impact, thus unlocking the true power of a 5-ton rice mill in communities poised for growth.

Enhancing Productivity Through Optimal Maintenance Practices

In the quest for productivity, the importance of maintenance cannot be overstated. Establishing a schedule for routine checks and repairs can dramatically boost the efficiency of a 5-ton rice mill. By implementing optimal maintenance practices, mill operators can ensure that machines operate smoothly without unexpected downtimes. Some key practices include:

- Regular Cleaning: Keeping the mill components free from dust and debris prevents mechanical failures and extends equipment life.

- Lubrication: Regularly oiling moving parts minimizes friction and wear, promoting efficient operation.

- Inspection: Conducting frequent inspections helps identify potential issues before they escalate into costly problems.

Understanding the cost-benefit relationship of maintenance can guide operators in making informed decisions. A well-maintained rice mill not only improves productivity but also ensures a consistent quality of output. The following table exemplifies the impact of proactive maintenance on operational efficiency:

| Maintenance Activity | Frequency | Impact on Efficiency |

|---|---|---|

| Cleaning | Weekly | +15% |

| Lubrication | Monthly | +10% |

| Full Inspection | Quarterly | +20% |

By adhering to these structured maintenance practices, operators can not only unlock the potential of a 5-ton rice mill but also foster a culture of precision and reliability that translates directly to enhanced productivity.

Sustainable Practices in Rice Milling for Long-Term Success

In today’s competitive agricultural landscape, embracing sustainable practices in rice milling is paramount for achieving both economic and environmental longevity. By implementing energy-efficient machinery, such as a state-of-the-art 5-ton rice mill, milling operations can significantly reduce their carbon footprint while optimizing output. Incorporating renewable energy sources, such as solar or wind power, not only minimizes dependence on fossil fuels but also positions rice mills as leaders in sustainable agricultural practices. This shift toward greener technology encourages resource conservation and fosters a more resilient supply chain.

Moreover, adopting water-efficient milling techniques can result in substantial cost savings and improved processing quality. Consider these strategies for enhancing sustainability:

- Eco-friendly waste management: Utilize by-products for animal feed or biofuel generation.

- Water recycling systems: Implement closed-loop systems that minimize water usage.

- Employee training: Educate staff on sustainable operation and maintenance practices.

- Regular equipment audits: Ensure machinery operates at peak efficiency to reduce waste and energy consumption.

By integrating these sustainable practices, rice milling operations not only comply with environmental regulations but also enhance their marketability. The table below highlights the key benefits associated with sustainable rice milling:

| Benefit | Description |

|---|---|

| Cost Savings | Lower energy and water bills significantly. |

| Market Advantage | Attract environmentally conscious consumers. |

| Resource Efficiency | Maximize raw material usage and minimize waste. |

| Improved Soil Health | Encourage rotation and organic practices. |

In Retrospect

As we draw the curtain on our exploration of the 5-ton rice mill, it becomes clear that this piece of agrarian technology is more than just a tool—it’s a catalyst for change in the rice production landscape. Its ability to streamline processes not only boosts productivity but also empowers local farmers, allowing them to optimize their yields and enhance their economic prospects.

In the intricate dance between tradition and innovation, the 5-ton rice mill stands as a testament to the potential of modern machinery to honor age-old practices while paving the way for a more efficient future. As we unlock the doors to efficiency, we open up endless possibilities for improvement in food security and sustainability.

As we close this chapter, let’s remember that the journey toward agricultural efficiency is ongoing, and every innovation counts. Embracing the power of the 5-ton rice mill is just one step on this path—one that holds the promise of a brighter, more productive tomorrow for farmers and consumers alike. Now, as we look to the future, may we continue to explore, innovate, and unlock even more efficiencies in the world of agriculture.