In an era where efficiency defines the success of agricultural practices, the humble rice mill has emerged as a beacon of innovation and productivity. The “5 Ton Rice Mill Revolution” is not just a technological upgrade; it is a transformative movement that is reshaping how we perceive rice processing. As global demand for rice continues to surge, millers are seeking solutions that not only enhance their output but also streamline their operations. This article delves into the mechanics and impact of the 5 ton rice mill, exploring how it harmonizes tradition with modern engineering to unlock unparalleled efficiency, reduce labor costs, and contribute to sustainable practices in an ever-evolving agricultural landscape. Join us as we explore this journey towards optimized rice production and the broader implications it holds for food security and economic growth in rice-producing regions across the globe.

Exploring the Technological Advancements in 5 Ton Rice Mills

In recent years, the landscape of rice milling has undergone significant transformation thanks to groundbreaking technological innovations. The 5 ton rice mill has emerged as a beacon of efficiency, incorporating advanced automation and smart features that cater to the evolving demands of modern agriculture. Key advancements include:

- Automation Systems: These mills now feature automated control systems that streamline processes, minimize labor costs, and reduce human error.

- Energy Efficiency: Enhanced energy management systems and the use of high-efficiency machinery have contributed to lower energy consumption, making operations more sustainable.

- Data Analytics: Real-time monitoring and data analytics empower mill operators to optimize production and quality control, leading to improved yield.

The transition to these contemporary milling technologies has not only improved output but also enhanced product quality. By employing cutting-edge milling techniques, rice mills can achieve higher degrees of white rice while preserving the nutritional value of the grains. In fact, a comparative analysis of traditional vs. modern milling methods reveals striking differences:

| Aspect | Traditional Milling | 5 Ton Rice Mill Advancements |

|---|---|---|

| Efficiency | 50-70% | 90-95% |

| Energy Consumption | High | Reduced by 30% |

| Labor Requirement | High | Significantly Lower |

| Product Quality | Standard | High-grade with Nutritional Retention |

This substantial leap in milling technology is helping producers meet both local and international market demands while ensuring food safety, sustainability, and profitability.

Enhancing Productivity through Streamlined Operations

In the competitive landscape of rice milling, the introduction of a 5 ton rice mill signifies a transformative leap towards operational efficiency. By implementing cutting-edge technology and advanced machinery, mills can significantly enhance their production capabilities. Focusing on key areas such as automated processing, real-time monitoring, and optimized resource allocation allows for reduced downtime and increased throughput. This shift not only streamlines workflows but also minimizes labor costs, enabling businesses to redirect resources toward innovation and growth.

To further illustrate the benefits of these sophisticated systems, consider the following advantages of streamlined operations in the rice milling process:

- Increased Output: High-capacity milling machines allow for larger batches, reducing production time.

- Quality Control: Automated systems improve consistency in product quality, ensuring better market acceptance.

- Waste Reduction: Enhanced extraction processes lead to higher yields, minimizing wasted materials.

- Energy Efficiency: Modern mills utilize energy-efficient technologies, contributing to sustainability efforts.

| Key Performance Metric | Before 5 Ton Mill | After 5 Ton Mill |

|---|---|---|

| Daily Production Capacity | 1.5 tons | 5 tons |

| Averaged Labor Hours | 40 hours | 25 hours |

| Waste Percentage | 10% | 2% |

These elements converge to create a resilient operational model, fostering an environment that prioritizes efficiency without compromising quality. As the rice milling industry continues to embrace these innovations, the potential for scaling operations while maintaining profitability becomes increasingly viable.

Sustainable Practices and Their Impact on Rice Milling Efficiency

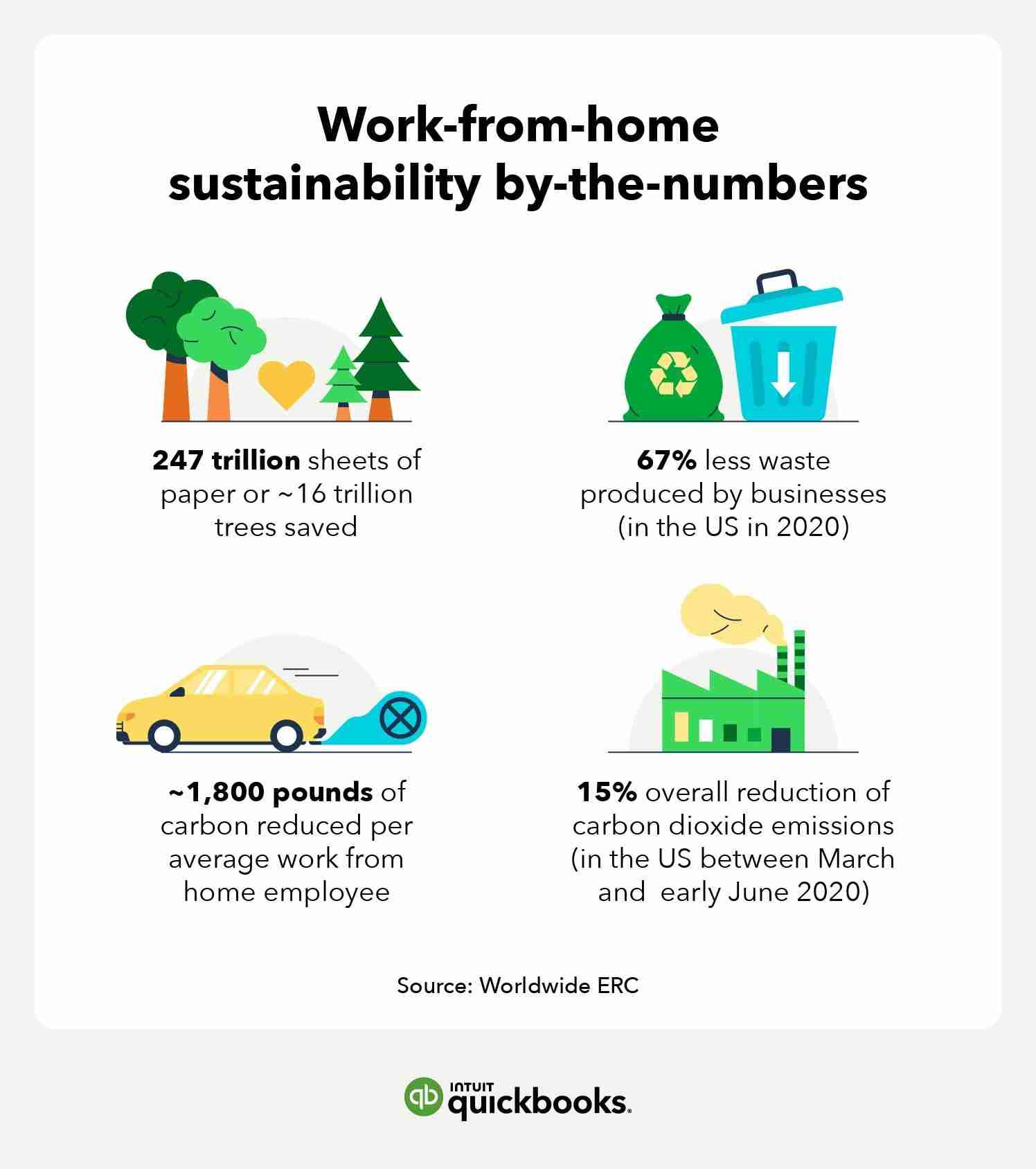

Implementing sustainable practices in rice milling operations not only safeguards the environment but also enhances overall efficiency and productivity. By adopting energy-efficient technologies, mills can significantly reduce their energy consumption, lowering operational costs while minimizing carbon footprints. Additionally, the integration of water conservation techniques helps in conserving this vital resource, ensuring that the milling process remains sustainable without compromising quality. Among these techniques are:

- Recirculating Water Systems: These systems significantly reduce water waste during the milling process.

- Efficient Waste Management: Utilizing husks and bran in bioenergy production can transform waste into a valuable resource.

- Solar Energy Utilization: Harnessing solar power for energy needs can lead to profound reductions in non-renewable energy use.

Incorporating these sustainable methods not only enhances milling efficiency but also positions companies as leaders in responsible production. A study analyzing the impact of various eco-friendly practices in rice mills revealed astonishing improvements in both economic and environmental metrics. The following table illustrates the differences:

| Practice | Impact on Efficiency | Cost Reduction (%) |

|---|---|---|

| Energy-efficient Machinery | 30% increase in output | 25% |

| Water Recycling | 20% water savings | 15% |

| Waste-to-Energy Systems | 10% energy savings | 20% |

By embracing these sustainable practices in rice milling, businesses not only improve their operational metrics but also contribute positively to their local communities and the ecosystem as a whole.

Investment Strategies for Maximizing Returns in Rice Milling

To enhance profitability in the rice milling sector, employing innovative investment strategies is crucial. Begin by focusing on technological advancements, which not only boost output but also reduce operational costs. Investing in high-efficiency milling machines equipped with automation can lead to significant gains. Furthermore, consider integrating sustainable practices within the milling process. This includes reducing energy consumption, minimizing waste, and utilizing renewable resources, which can lower expenses while appealing to environmentally conscious consumers.

Another advantageous strategy is to prioritize diversification. By expanding product offerings to include various rice types and value-added products like rice flour or bran oil, businesses can tap into different markets and mitigate risks. Building strategic partnerships with local farmers can also foster a steady supply chain and ensure quality inputs at competitive prices. employing robust marketing strategies can amplify visibility and demand. Utilizing digital platforms for marketing can attract a broader customer base, ultimately driving growth and enhancing investment returns.

Future Outlook

the evolution of the 5-ton rice mill stands at the crossroads of tradition and innovation, embodying a significant leap towards enhanced agricultural efficiency. As we have explored, these mills offer not only the promise of increased productivity but also a sustainable solution to the challenges faced by modern rice farming. By embracing advanced technologies and best practices, farmers can unlock new potential, ensuring better livelihoods and food security for generations to come.

As the rice industry continues to evolve, the commitment to harnessing such revolutionary tools will be crucial. Whether you are a farmer, an agricultural entrepreneur, or simply an aficionado of effective practices, the journey towards improving rice milling operations is an exciting one. Let us nurture this momentum, for in doing so, we not only elevate the process of rice production but also celebrate the heart and soul of agrarian life. The future of rice milling looks bright, and with it, so does the promise of efficiency and sustainability.