Transforming Grains: The Journey Through a Rice Processing Plant

In the heart of agricultural landscapes, where golden fields sway gently under the sun, lies a world often unnoticed yet vital to our daily sustenance: the rice processing plant. Here, the simple grain undergoes a remarkable transformation, evolving from modest sheaves to the polished pearls that grace our plates. This journey, though unseen by many, is a complex symphony of technology and tradition, where nature’s bounty is meticulously refined to feed millions. From the moment the harvested paddy arrives at the plant, to its final packaging as a staple food, each step is a testament to the intricate processes that bridge raw agriculture and culinary delight. Join us as we delve into the fascinating world of rice processing, exploring the machinery, techniques, and the dedicated hands that bring this essential grain to fruition.

Understanding the Rice Processing Journey from Field to Plate

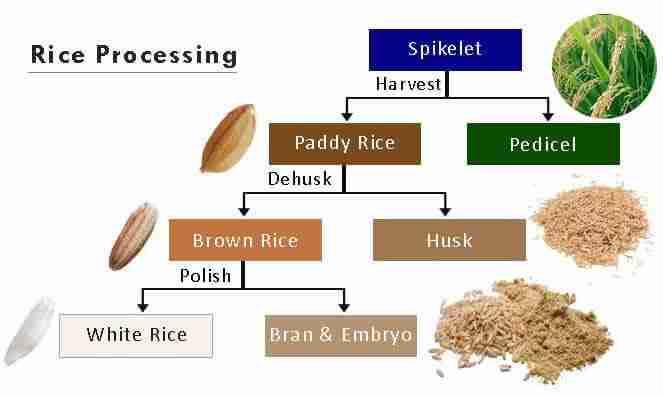

The journey of rice from the farm to your plate is a fascinating transformation, marked by various stages that ensure the grains maintain their quality and flavor. After harvesting, rice undergoes a process called threshing, where the grains are separated from the stalks. Following this, a rigorous cleaning process takes place to remove impurities such as dirt, stones, and other foreign materials. This is typically done using vibrating screens or air classifiers, which effectively eliminate waste and prepare the rice for further processing. The next step is drying, essential for reducing moisture content and preventing spoilage. This process ensures the rice is in optimal condition for storage and future milling.

Once dried, the rice enters the milling phase, where the grains are hulled to remove the outer husk, followed by the removal of the bran layer, resulting in white rice. The quality of the milling can significantly affect the final product’s taste and texture, making it a crucial step in the journey. After milling, rice undergoes a final polishing process, which enhances its appearance and shelf life. The processed rice is then packaged for distribution, ready to make its way to kitchens around the world. Here’s a quick overview of the essential stages:

| Stage | Description |

|---|---|

| Harvesting | Collecting ripe rice grains from the fields. |

| Threshing | Separating grains from the stalks. |

| Cleaning | Removing impurities and foreign materials. |

| Drying | Reducing moisture content to prevent spoilage. |

| Milling | Hulling and polishing the rice grains. |

| Packaging | Preparing rice for distribution. |

The Role of Technology in Enhancing Rice Quality and Efficiency

In contemporary rice processing plants, technology assumes a pivotal role in boosting both the quality of the final product and the operational efficiency of the entire process. Advanced machinery equipped with AI algorithms and IoT sensors facilitates precise monitoring throughout the production line. This infusion of technology allows for real-time adjustments in processing variables, significantly reducing waste and maintaining consistency in grain size and quality. For instance, automated sorting systems utilize machine vision to classify rice based on color, size, and shape, ensuring only the highest quality grains make the final cut.

Furthermore, technology streamlines logistics and inventory management, fostering a seamless workflow from rice milling to packaging. The integration of cloud-based systems enables transparent tracking of inventory levels and provides data analytics that guide strategic decision-making. Consider the following efficiencies realized through these technological advancements:

| Technology | Impact |

|---|---|

| Automated Quality Control | Enhances consistency and reduces errors |

| Data Analytics | Optimizes inventory management and forecasting |

| IoT Sensors | Improves real-time monitoring of conditions |

| AI-Driven Sorting | Increases efficiency in quality assessment |

By embracing these innovations, rice processing plants not only elevate the quality of their produce but also push the boundaries of operational efficiency. Enhanced processing techniques supported by technology are paving the way for a sustainable future in rice production, ensuring that every grain served on the table meets the highest standards, while also addressing the growing demand for rice worldwide.

Sustainable Practices in Rice Processing: Balancing Harvest and Environment

In the intricate ballet of rice processing, sustainability plays a crucial role in ensuring that the delicate balance between harvest and environmental stewardship does not tip. Modern rice processing plants are adopting eco-friendly technologies that reduce waste and energy consumption, creating a symbiosis between production and preservation. Among these innovative practices are:

- Water Conservation Techniques: Utilizing closed-loop systems to recycle water and minimize excessive use.

- Energy-Efficient Machinery: Implementing low-energy-consuming equipment that cuts down on greenhouse gas emissions.

- Minimized Waste Production: Converting byproducts into useful materials, such as rice husk briquettes for biofuel.

The journey through a rice processing plant not only transforms grains but also embodies a commitment to sustainable agriculture. By integrating social responsibility with modern practices, rice processors are fostering an ecosystem where economic growth does not compromise environmental integrity. This is further exemplified by:

| Sustainable Practice | Impact |

|---|---|

| Organic Farming | Enhances soil health and biodiversity |

| Carbon Sequestration | Reduces atmospheric CO2 levels |

| Community Engagement | Supports local economies and promotes fair trade |

Navigating Challenges and Innovations in the Rice Supply Chain

As the demand for rice continues to rise globally, navigating the complexities of the supply chain becomes increasingly critical. Each stage, from paddy cultivation to processing, is fraught with challenges driven by climate unpredictability, labor shortages, and logistical constraints. Producers must constantly adapt by adopting innovative agritech solutions such as precision farming tools and sustainable practices. In a modern rice processing plant, the harmony of technology and traditional methods helps mitigate the risks associated with quality control and efficiency. Balancing automation with human oversight ensures that only the best grains make it to market, enhancing both reliability and profitability.

Moreover, the integration of data analytics into supply chain management offers a significant advantage. By leveraging real-time information, stakeholders can optimize various processes, from inventory management to transportation logistics. Key strategies include:

- Predictive Analytics: Anticipating demand fluctuations to minimize waste.

- Supply Chain Transparency: Utilizing blockchain for traceability in sourcing.

- Resource Optimization: Implementing energy-efficient technologies to reduce environmental impact.

To illustrate the current trends in rice processing efficiency and innovation, consider the following table:

| Innovation | Impact |

|---|---|

| Automated Milling Systems | Increased production speed and consistency |

| Quality Control Sensors | Enhanced grading and sorting accuracy |

| Sustainable Packaging Solutions | Reduced environmental footprint and waste |

Concluding Remarks

As the sun sets over the agricultural landscape, the journey of rice from the paddy field to our plates undergoes a remarkable transformation within the bustling walls of a processing plant. Each grain tells a story, woven together through cycles of cultivation, harvesting, and meticulous processing. It’s a journey marked by innovation and tradition, where modern machinery and age-old techniques converge to bring out the best in each grain.

In this intricate dance of technology and nature, we’ve witnessed how the humble rice kernel is polished and prepared, evolving from its raw state into a staple that nourishes millions around the globe. The journey through a rice processing plant is not just a process; it’s a testament to the dedication of farmers, millers, and craftsmen who strive to honor both the grain’s heritage and its future.

As we conclude this exploration, let us reflect on the unseen labor and craftsmanship that elevates a simple grain into a culinary cornerstone. Each spoonful of rice encapsulates a voyage steeped in culture, innovation, and respect for the earth. As we celebrate this journey, may we remain mindful of the hands that work tirelessly to ensure that our tables are graced with this essential food—a symbol of sustenance, community, and connection across borders and generations.