In the realm of agriculture and food processing, the quest for quality has always been paramount. Enter the Jet Rice Polisher—a cutting-edge innovation that promises to redefine how we approach grain refinement. As the global demand for superior grain products continues to rise, this revolutionary machinery stands at the forefront, merging technology with tradition to enhance the quality of rice like never before. By harnessing the principles of aerodynamics and precision engineering, the Jet Rice Polisher not only elevates the aesthetic appeal of grains but also boosts their nutritional value. In this article, we will delve into the workings of this remarkable device, explore its impact on the rice industry, and examine how it is setting new standards for grain quality amidst a backdrop of evolving consumer expectations. Join us as we unveil the transformative potential of the Jet Rice Polisher and its role in shaping the future of one of the world’s most essential staple foods.

Exploring the Innovative Design of the Jet Rice Polisher

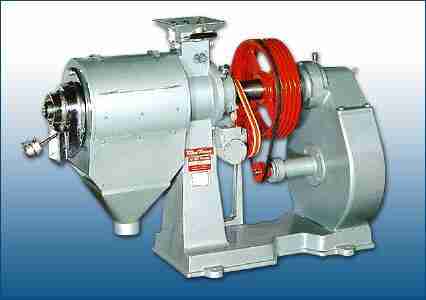

The design of the Jet Rice Polisher stands as a testament to cutting-edge engineering, harmonizing functionality with efficiency. At its core, the polisher utilizes a unique air flow system that minimizes breakage while maximizing polishing, ensuring that the grains emerge polished without compromising their integrity. This innovative mechanism not only enhances the aesthetic appearance of rice but also improves its storage qualities by reducing moisture retention.

In addition to its advanced air flow technology, the polisher features a user-friendly interface that allows operators to adjust settings with precision, catering to varying grain types and quality standards. The device is compact yet surprisingly robust, designed to fit seamlessly into any grain processing setup. Key features include:

- High Efficiency: Polishes grains quickly, enhancing productivity.

- Minimized Waste: Reduces grain loss during the polishing process.

- Durable Construction: Built to withstand rigorous use in commercial environments.

Moreover, the Jet Rice Polisher incorporates smart sensors that monitor grain conditions, optimizing polishing conditions in real-time. This integration of technology safeguards the quality of the final product, bridging traditional knowledge with modern innovation. Below is a comparison of the Jet Rice Polisher with conventional methods:

| Feature | Jet Rice Polisher | Conventional Methods |

|---|---|---|

| Polishing Speed | High | Moderate |

| Grain Damage | Minimal | Higher |

| Technology | Smart Sensor Integration | Manual Adjustments |

Understanding the Science Behind Enhanced Grain Quality

The exploration of grain quality enhancement hinges on innovative technologies that reshape our understanding of traditional processing methods. One such leap is exemplified by the Jet Rice Polisher, which integrates advanced aerodynamics and precision engineering to revolutionize rice polishing. By utilizing controlled airflows, it minimizes grain fractures while maximizing the removal of impurities, thereby preserving the essential qualities of the rice. This sophisticated method contrasts starkly with older polishing techniques that often resulted in significant nutrient loss and damaged grains, ensuring that each rice kernel not only meets market standards but also retains its nutritional integrity.

In addition to mechanical advancements, the science behind grain quality can be understood through the physical properties of the rice itself. The Jet Rice Polisher employs a unique polishing chamber design that enhances both efficiency and effectiveness. Key factors influencing the final product quality include:

- Pressure Control: Balancing internal pressure significantly reduces breakage.

- Temperature Regulation: Prevents overheating, which could negatively affect taste and texture.

- Optimum Polishing Time: Ensures a thorough polish without compromising grain structure.

Table 1 below summarizes the comparison of traditional methods and the Jet Rice Polisher:

| Parameter | Traditional Method | Jet Rice Polisher |

|---|---|---|

| Grain Breakage | High | Low |

| Nutrient Retention | Moderate | High |

| Processing Time | Long | Short |

This holistic approach to grain quality not only elevates the end product but also offers agricultural producers a competitive edge in an increasingly demanding market. As the understanding of these scientific principles expands, it heralds a new era in grain processing, driven by technology and research.

Evaluating the Impact on Sustainability and Efficiency

In the realm of grain processing, the introduction of innovative technologies often translates to significant strides in sustainability and operational efficiency. The Jet Rice Polisher exemplifies this, integrating advanced aerodynamic principles that minimize energy consumption and waste. By using a method that is both gentle and effective, the Jet Rice Polisher not only enhances the quality of rice but does so with a significantly reduced environmental footprint. Key benefits of this approach include:

- Lower Water Usage: The polisher employs a unique dry-polishing technique, decreasing reliance on excessive water.

- Reduced Energy Consumption: Optimized airflow reduces the energy needed for processing, leading to lower operational costs.

- Minimal Grain Loss: The design ensures that a higher percentage of grain is polished without excessive waste.

Furthermore, the Jet Rice Polisher contributes to overall supply chain sustainability by facilitating local milling operations and reducing transportation emissions. With a focus on enhancing efficiency in various stages of processing, the equipment aids small and medium-sized enterprises in becoming more competitive without compromising on quality or environmental responsibility. Here’s a snapshot of how the Jet Rice Polisher stands out:

| Feature | Standard Polishers | Jet Rice Polisher |

|---|---|---|

| Water Requirement | High | Low |

| Energy Efficiency | Average | High |

| Grain Retention | Moderate | High |

Practical Tips for Implementing the Jet Rice Polisher in Milling Operations

Integrating the Jet Rice Polisher into your milling operations can significantly enhance the quality of rice produced. To ensure a seamless implementation, start by training your staff on the machinery. Proper usage techniques will not only improve efficiency but also help prevent potential mishaps. Consider organizing hands-on workshops where operators can familiarize themselves with the equipment, learn about maintenance, and troubleshoot common issues. Additionally, having a designated team member to oversee the polishing process can provide continuous support and optimize output.

Another critical aspect of successful implementation lies in fine-tuning the settings of the Jet Rice Polisher according to your specific needs. Different varieties of rice may require adjustments in polishing time and pressure. It is advisable to conduct trial runs with various adjustments, documenting outcomes such as grain breakage rates and polishing effectiveness. This experimentation phase can include:

- Assessing moisture content levels before polishing

- Monitoring temperature during processing

- Evaluating product quality post-polishing

Through this systematic approach, you can arrive at the optimal settings that maximize both quality and yield, setting a new standard in your milling operations.

The Conclusion

the Jet Rice Polisher stands as a groundbreaking advancement in the pursuit of grain quality, merging innovative technology with time-honored agricultural practices. By enhancing the efficiency of rice polishing, it not only elevates the aesthetic appeal of the grain but also preserves its nutritional integrity, a vital consideration in today’s health-conscious market. As farmers and producers increasingly adopt this cutting-edge solution, the ripple effects promise to reshape the landscape of grain processing, bringing forth products that meet the evolving demands of consumers worldwide. Embracing such transformative tools may very well set the stage for a brighter, more sustainable future in the world of agriculture, where quality and innovation walk hand in hand. As we move forward, one must wonder: what other game-changing technologies lie on the horizon, waiting to redefine our relationship with food and production?