In an era where every grain counts, the quest for efficiency in rice production has become a paramount concern for farmers and mill operators alike. Enter the 5-ton rice mill—a powerhouse of productivity designed to meet the burgeoning demands of an ever-growing population while ensuring quality and sustainability. This article embarks on a journey to explore the intricacies of 5-ton rice mills, delving into their operational mechanics, cost-effectiveness, and the role they play in revolutionizing the rice milling industry. Join us as we unravel the comprehensive landscape of these efficient machines, providing valuable insights for those looking to enhance their milling practices and optimize their yields. Whether you are a seasoned miller or a curious newcomer, this guide promises to illuminate the path toward harnessing the full potential of rice milling technology.

Unlocking Production Potential of 5-Ton Rice Mills

Unlocking the production potential of 5-ton rice mills requires understanding their operational capabilities and leveraging innovative techniques. These mills are designed to cater to small- and medium-scale rice processing needs, delivering efficiency while meeting the demands of local markets. To maximize output, operators can focus on several key factors: maintenance practices, workforce training, and quality assurance protocols. Implementing regular maintenance schedules helps avoid unexpected downtime and prolongs the lifespan of machinery, while comprehensive training programs empower workers to operate equipment effectively and troubleshoot issues as they arise.

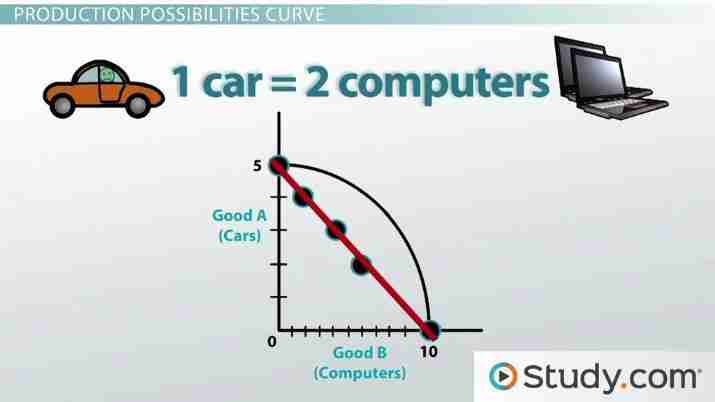

Moreover, integrating modern technology into traditional milling practices can significantly enhance productivity. Automated systems for sorting, grading, and packaging rice not only speed up processes but also improve consistency in product quality. A detailed comparison of output and efficiency metrics can be defined in the table below, showcasing the advantages of adopting innovative practices in 5-ton rice mills:

| Aspect | Traditional Method | Modernized Approach |

|---|---|---|

| Processing Time (Hours) | 8 | 4 |

| Labor Requirement (Workers) | 10 | 5 |

| Production Yield (Tons) | 4 | 5 |

| Energy Consumption (kWh) | 100 | 75 |

By focusing on these strategic enhancements and drawing on data-driven insights, operators can effectively unlock the full potential of 5-ton rice mills. This not only leads to a higher profit margin but also improves sustainability within the rice milling industry.

Key Features that Enhance Efficiency in Rice Milling

In the realm of rice milling, several key features significantly contribute to operational efficiency. Automated systems play a pivotal role in reducing manual labor, ensuring that tasks such as husking, polishing, and sorting are performed swiftly and accurately. Additionally, the integration of energy-efficient motors helps in lowering operational costs while enhancing productivity. Features like advanced moisture control technologies promote better quality rice by preventing spoilage, hence maximizing profitability and minimizing waste.

Moreover, user-friendly interfaces within modern mills facilitate ease of operation and allow for quicker adjustments during different milling processes. This flexibility is complemented by real-time monitoring systems, which provide operators with essential data on machine performance and product quality. Utilizing a combination of durable materials and robust designs ensures longevity, reducing downtime and maintenance costs. these features culminate in an optimized milling process, promoting both efficiency and profitability in rice milling operations.

Maintenance Best Practices for Long-Lasting Performance

To ensure the longevity and efficient operation of 5-ton rice mills, adhering to a stringent maintenance routine is essential. Regularly inspecting components, such as the husker, separator, and grinder, can help identify wear and tear before it leads to significant malfunctions. Key practices to consider include:

- Daily Cleaning: Remove dust and debris from the machinery to prevent clogging and enhance airflow.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and wear.

- Calibration: Regularly calibrate settings for optimal performance and consistency in output quality.

- Component Replacement: Schedule timely replacement of parts showing signs of fatigue, especially belts and screens.

Monitoring operational metrics can also provide insight into the machine’s health. Establishing a maintenance log can help track repairs, part replacements, and service dates, ensuring no vital checks are missed. Below is an example of a useful record-keeping format:

| Date | Maintenance Task | Status | Next Scheduled Maintenance |

|---|---|---|---|

| 01/10/2023 | Husker Inspection | Completed | 01/11/2023 |

| 01/15/2023 | Lubrication of Gears | Completed | 01/30/2023 |

| 01/20/2023 | Screen Replacement | Pending | 01/25/2023 |

Cost-Benefit Analysis: Maximizing Profitability in Rice Processing

Conducting a thorough analysis of costs and benefits is paramount for rice mill operators aiming to enhance profitability. The operation of 5-ton rice mills can incur various costs, including equipment purchase, maintenance, labor, and utilities. To effectively evaluate the potential profitability, it’s crucial to assess both fixed costs (those that do not change with production volume) and variable costs (which fluctuate as production levels change). By understanding these expenses, mill owners can identify cost-cutting opportunities without compromising quality and allow for more accurate financial forecasting.

In addition to evaluating costs, it is equally important to understand the benefits that arise from implementing efficient processing methods. The advantages of optimizing rice processing include increased yield, higher quality output, and improved operational efficiency. Notably, a comprehensive assessment may reveal the following key benefits:

- Higher market price: Quality rice can fetch a premium price.

- Lower waste: Enhanced processing can reduce by-product loss.

- Better labor productivity: Streamlined operations may require fewer personnel.

- Energy savings: Efficient machines can significantly lower utility bills.

| Cost Type | Estimated Cost (per month) | Benefit Type | Estimated Benefit (per month) |

|---|---|---|---|

| Fixed Costs | $1,500 | Premium Product Sales | $3,000 |

| Variable Costs | $1,000 | Reduced Waste Value | $500 |

| Labor Costs | $2,000 | Increased Production Rate | $2,500 |

Insights and Conclusions

the exploration of 5-ton rice mills reveals not just a technological marvel but also a vital component in the agriculture and food production sectors. As we’ve uncovered, these machines balance efficiency with scalability, catering to both small-scale farmers and larger operations alike. Their capacity to process rice swiftly and effectively fosters not only economic growth but also contributes to food security in communities across the globe.

As we move forward, the ongoing innovation in rice milling technology promises even greater advancements in efficiency, sustainability, and user accessibility. For anyone invested in the agricultural landscape—whether you’re a farmer, mill owner, or industry enthusiast—the 5-ton rice mill stands as a beacon of progress, illustrating how modern machinery can transform age-old practices into streamlined, productive operations.

By embracing these technologies, we can cultivate a future where rice milling supports we thrive—one grain at a time. Thank you for joining us on this comprehensive journey; we hope it inspires you to delve deeper into the world of rice milling and explore the potential it holds for enhancing both livelihoods and communities worldwide.