Unlocking Potential: The Journey of Rice Processing Plants

In the heart of countless agricultural landscapes lies a humble yet transformative enterprise: the rice processing plant. These facilities serve as the crucial link between the fields of golden grain and the dining tables of millions around the world. As the global demand for rice continues to rise, so too does the need for innovative processing techniques that enhance quality, efficiency, and sustainability. This article explores the multifaceted journey of rice processing plants—unraveling the intricate phases of production, examining the technology that drives advancements, and reflecting on the socio-economic impacts within rice-growing communities. Join us as we unlock the potential of these vital hubs of food production, charting a course through their past, present, and future.

Understanding the Rice Processing Lifecycle for Enhanced Quality Control

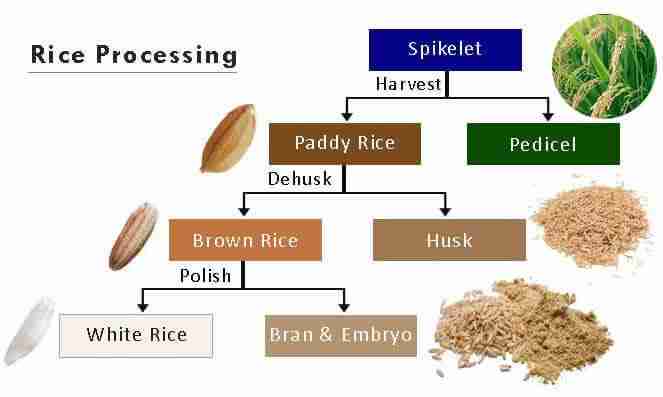

The journey of rice processing is a meticulous orchestration of several stages, each contributing uniquely to the final product’s quality. Beginning with paddy harvesting, it is crucial to time this stage perfectly as moisture levels and timing significantly impact the overall quality. Once harvested, the paddy undergoes drying. This stage is pivotal in preventing spoilage and microbial growth, setting the foundation for effective processing. Following this, the paddy enters the milling phase, which includes hulling and whitening. Precision in this stage ensures that the bran layer is effectively removed while maintaining the integrity of the rice grain. Each of these phases must be carefully monitored, creating a seamless flow of quality control.

As the rice continues its journey, the grading and packaging stages serve to finalize its market readiness. In the grading phase, rice is sorted based on size and quality, using advanced technology for accuracy, which directly affects consumer perception and satisfaction. This is followed by the packaging, where protective and appealing designs play a significant role in the product’s-market allure. To enhance quality control, statistical process control (SPC) methods are often implemented, offering a data-driven approach to ensure consistency. Observing these stages underpins the importance of an integrated processing lifecycle that ultimately leads to a superior product reaching the consumer’s table.

| Stage | Description | Quality Control Focus |

|---|---|---|

| Paddy Harvesting | Timely harvesting to ensure optimal moisture levels | Moisture content analysis |

| Drying | Removal of excess moisture to prevent spoilage | Temperature and humidity monitoring |

| Milling | Hulling and whitening of rice grains | Grain integrity assessment |

| Grading | Sorting rice by size and quality | Use of technology for accuracy |

| Packaging | Designing appealing protective packages | Consumer feedback analysis |

Innovative Technologies Revolutionizing Rice Processing Efficiency

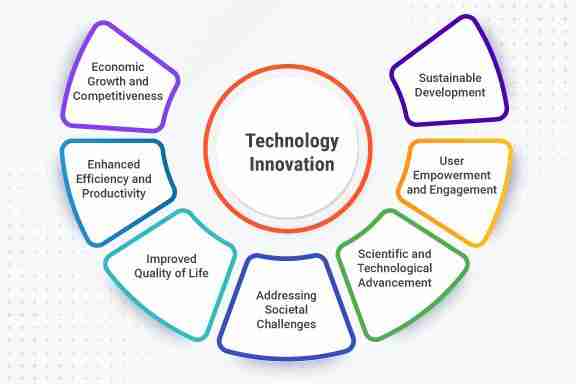

The rice processing industry is undergoing a remarkable transformation, thanks to an array of cutting-edge technologies designed to enhance efficiency and productivity. Among these innovations are automated sorting machines, which utilize advanced optical sensors and AI algorithms to ensure only the highest quality grains make it to market. This not only reduces waste but also significantly increases the overall quality of the final product. Additionally, smart grain storage systems equipped with IoT sensors monitor humidity and temperature to preserve rice quality during storage, preventing mold and spoilage while maximizing shelf life.

Furthermore, the integration of machine learning into processing operations allows for predictive maintenance of machinery. This reduces downtime and ensures that equipment is always operating at peak performance. Another noteworthy development is the use of sustainable energy solutions, such as solar-powered mill plants, which lower energy costs and carbon footprints. These innovations not only streamline operations but also promote a greener approach to rice processing, leading the industry toward a more sustainable future.

Sustainable Practices in Rice Processing: Balancing Profit and Preservation

As the demand for rice continues to rise globally, processing plants face the dual challenge of maintaining profitability while adopting eco-friendly methods. Sustainable practices such as energy-efficient machinery, water recycling systems, and waste minimization strategies are becoming essential components of modern rice processing. By investing in these systems, plants can reduce their carbon footprint and operating costs, creating a win-win situation that benefits both the environment and the bottom line. Key initiatives include:

- Utilizing solar energy to power operations

- Circular water use through advanced filtration techniques

- Implementing green waste management for rice husk and bran

Moreover, collaboration with local farmers can help ensure that rice is cultivated using sustainable methods, creating an entire ecosystem of responsibility and care. Processing plants can play a significant role in this by providing training and support for environmentally conscious farming practices. Additionally, adopting certifications for organic or sustainable rice can enhance market appeal and consumer trust. Below is a table comparing traditional versus sustainable rice processing methodologies:

| Aspect | Traditional Processing | Sustainable Processing |

|---|---|---|

| Energy Use | High reliance on fossil fuels | Renewable energy sources |

| Water Consumption | High and inefficient | Recycling and conservation methods |

| Waste Management | Linear waste disposal | Circular economy models |

Strategies for Workforce Development in Rice Processing Facilities

Building a competent workforce in rice processing facilities requires a multifaceted approach that emphasizes both technical skills and personal development. Establishing comprehensive training programs that incorporate hands-on experience is essential. Facilities can achieve this by implementing mentorship initiatives, where seasoned employees guide newcomers through complex processes, ensuring knowledge transfer and fostering a culture of teamwork. Investing in continuous education, such as workshops focusing on the latest processing technologies, not only enhances employee skills but also keeps the facility competitive in a rapidly evolving market.

Additionally, fostering an environment of inclusivity and respect can significantly enhance workforce morale and productivity. Regularly conducting feedback sessions allows employees to voice their suggestions and concerns, promoting a sense of ownership and engagement. Facilities can further benefit from establishing career progression pathways, providing clear incentives for employees to develop their skills and advance within the company. The following table outlines key strategies aimed at enriching the workforce in rice processing environments:

| Strategy | Description |

|---|---|

| Technical Training | Hands-on workshops focusing on processing equipment and safety protocols. |

| Mentorship Programs | Pairing experienced employees with new hires for skill development. |

| Feedback Mechanisms | Regular sessions for employees to contribute ideas and concerns. |

| Career Pathways | Clear guidelines for advancement and opportunities for further training. |

To Wrap It Up

As we conclude our exploration of rice processing plants, we find ourselves at the intersection of tradition and innovation, where dedicated hands meet cutting-edge technology. This journey not only encapsulates the intricate methods that transform raw grains into a staple of global diets but also reflects a commitment to sustainability, efficiency, and community empowerment. Each plant stands as a testament to human ingenuity, playing a crucial role in food security and economic development.

By unlocking the potential of rice processing, we honor the traditions of countless farmers while embracing the advancements that pave the way for a more sustainable future. The paths taken by these plants remind us that behind every grain lies a story—of resilience, transformation, and the shared ambition to nourish the world. As we look ahead, let us continue to support and innovate within this essential industry, ensuring that its journey contributes to a thriving, equitable future for all.