In the heart of many cultures and economies, rice stands as a staple food, nourishing billions and serving as a culinary cornerstone across continents. Yet, behind the scenes of this beloved grain’s journey from field to fork, a transformation unfolds—one powered by an array of intricately designed processing machines. This article delves into the world of rice processing technology, exploring how these mechanical marvels are redefining the rice value chain. From husking to polishing, each stage of processing enhances not only the quality and shelf life of rice but also the livelihoods of farmers and communities reliant on this essential crop. Join us as we uncover the pivotal role that rice processing machines play in bridging tradition and innovation, ensuring that this humble grain continues to sustain generations to come.

The Evolution of Rice Processing Technology and Its Impact on Quality

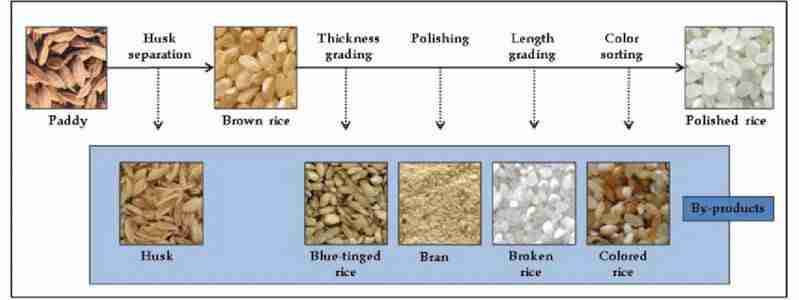

As rice processing technology evolved over the decades, it has significantly transformed both the efficiency and quality of rice production. Early techniques involved manual labor and rudimentary tools, leading to an inconsistent output and often poor grain quality. However, the introduction of mechanization changed the landscape entirely. Modern machines, such as millers, huskers, and sorters, utilize advanced materials and engineering designs aimed at reducing grain breakage and improving overall yield. Not only do these sophisticated machines enhance processing speed, they also minimize human error and inconsistencies inherent in manual methods.

Today, rice processing machines are equipped with innovations like optical sorting technologies and computerized controls, paving the way for precision in the milling process. The impact of these advancements is multifaceted, as they ensure a higher degree of purity, whiteness, and texture in the final product. Enhancements in energy efficiency and waste management further contribute to a more sustainable approach to rice processing. The table below summarizes the major technological advancements and their corresponding impacts on rice quality:

| Technology | Impact on Quality |

|---|---|

| Mechanical Huskers | Reduced grain damage and improved kernel integrity |

| Optical Sorters | Enhanced purity by eliminating discolored grains |

| Automated Milling Machines | Consistent particle size and texture, leading to better cooking quality |

| Energy-efficient Equipment | Lower environmental impact and reduced operational costs |

The integration of these advanced technologies showcases an industry moving towards not only greater efficiency but also enhanced sensory and nutritional properties of rice. Producers can now meet increasing consumer demands for premium quality rice with a minimal ecological footprint. As we continue to innovate, it paves the way for a brighter future for rice processing, ultimately ensuring food security and sustainability on a global scale.

Maximizing Efficiency: Understanding the Functionality of Modern Rice Mill Machines

Modern rice mill machines have revolutionized the rice processing industry by enhancing productivity and ensuring the highest standards of quality in rice milling. These machines are designed with advanced technology that optimizes every stage of the milling process. From pre-cleaning to hulling and polishing, rice mill machines streamline operations, reducing manual labor and minimizing losses. Key features such as automatic feeding, dust removal systems, and efficient separation mechanisms ensure the rice is processed with minimal waste. The integration of smart technology allows for real-time monitoring and adjustments, providing mill owners with data to fine-tune operations for maximum efficiency.

The functionality of these machines encompasses a range of processes, each contributing to the overall quality of the final product. Notably, modern rice mills typically include:

- Dehusking Units: These efficiently remove the outer husk without damaging the grain.

- Milling Sections: These transform brown rice into white rice, ensuring optimal grain shape and size.

- Grading Machines: These classify rice based on size and quality to meet market demands.

- Packaging Systems: These automate the final step, ensuring prompt and safe distribution to consumers.

| Feature | Benefit |

|---|---|

| Automation | Reduces human error and labor costs. |

| Energy Efficiency | Lower energy consumption leads to cost savings. |

| Quality Control | Ensures consistent product quality and high market standards. |

Sustainability in Grain Processing: Eco-Friendly Practices and Innovations

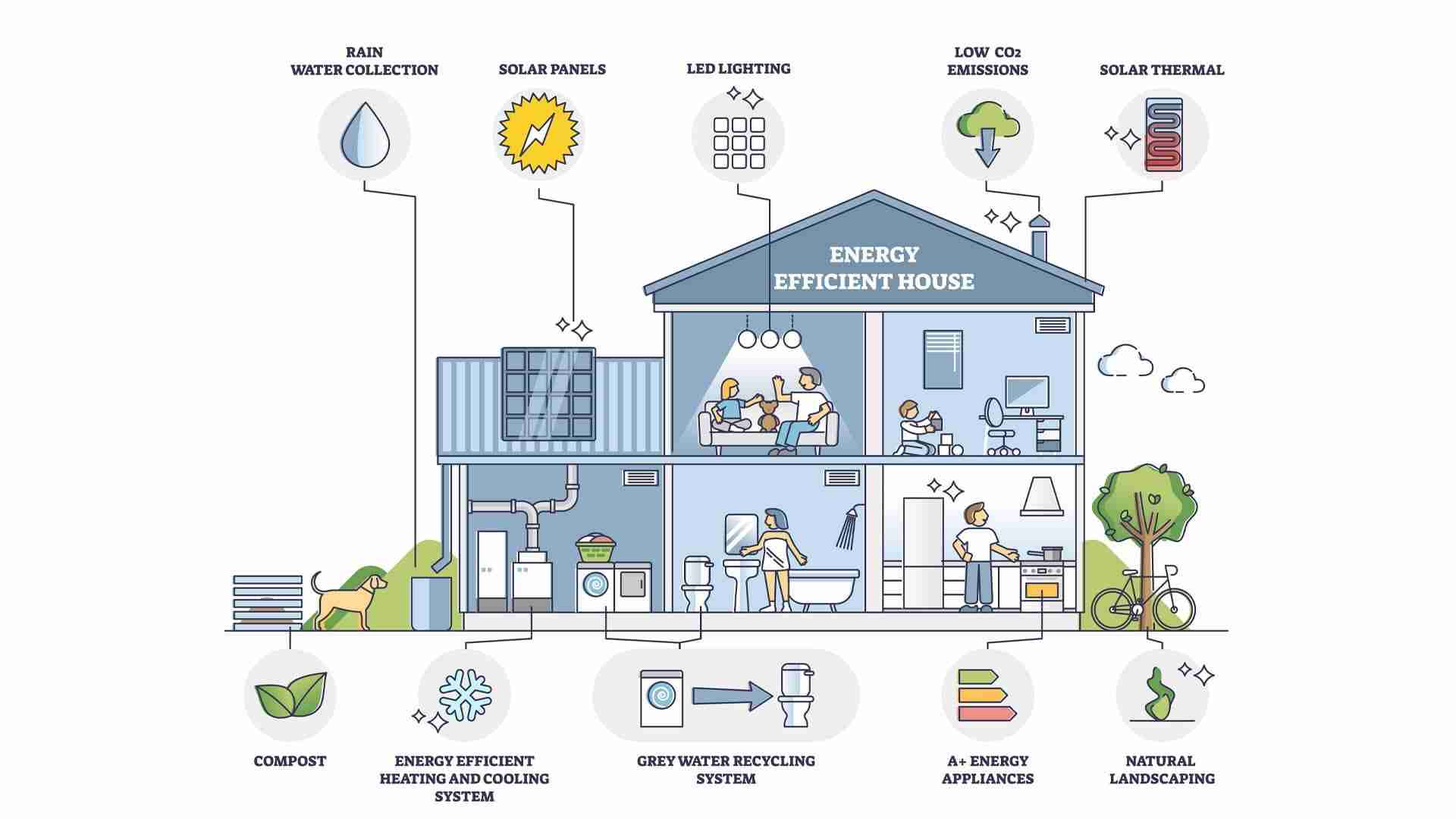

In the ever-evolving landscape of food production, embracing eco-friendly practices in grain processing is more crucial than ever. Rice processing machines are at the forefront of this transformation, driving innovations that not only enhance efficiency but also minimize environmental impact. By incorporating advanced technologies, these machines reduce energy consumption and waste, contributing to a more sustainable agricultural sector. Key innovations include:

- Low-Impact Milling Techniques: Utilizing gentle milling processes helps maintain the nutritional integrity of rice while minimizing waste.

- Water Conservation Systems: Implementing closed-loop water systems to recycle and reuse water during processing reduces overall consumption.

- Renewable Energy Sources: Many facilities are turning to solar and wind energy to power their operations, decreasing reliance on fossil fuels.

Furthermore, manufacturers are increasingly adopting eco-conscious practices in the supply chain, reinforcing the commitment to sustainability. For instance, the use of biodegradable packaging materials and the promotion of local sourcing contribute to a significantly lower carbon footprint. By empowering farmers with eco-friendly rice processing machines, the agricultural community can foster a more sustainable economy. Here’s a simple comparison of different processing methods:

| Processing Method | Energy Use | Waste Production |

|---|---|---|

| Traditional Milling | High | Significant |

| Eco-Friendly Milling | Reduced | Minimal |

Future Trends in Rice Processing Equipment: What to Expect for the Industry

The rice processing industry is on the cusp of a technological renaissance, promising to reshape the landscape of grain transformation. Automation is set to take center stage, with advanced robotics and AI-driven systems enabling more efficient operations and minimizing human intervention. These innovations will not only enhance productivity but also improve precision, ensuring that each grain is processed with optimal care. Enhanced data analytics will also become crucial, providing insights that drive decision-making in real-time, from monitoring quality control to optimizing supply chains. The integration of IoT devices will facilitate seamless communication across different stages of production, allowing for better troubleshooting and maintenance practices.

Furthermore, sustainability will play a pivotal role in the evolution of rice processing equipment. Manufacturers are increasingly focusing on energy efficiency and waste reduction, introducing machinery designed to minimize environmental impact. Emerging technologies such as solar-powered systems and biomass energy solutions promise to lower carbon footprints while maintaining operation performance. Key developments to look out for include:

- Smart Sorting Technologies: Utilizing AI for better grain selection and quality grading.

- Multi-functional Machinery: Reducing the need for multiple machines by combining processes such as milling and polishing.

- Water Conservation Features: Incorporating systems that recycle water used in processing.

To Conclude

As we conclude our exploration of the pivotal role rice processing machines play in transforming one of the world’s most essential grains, it becomes clear that these innovations are more than just tools; they are catalysts for change. By enhancing efficiency, preserving quality, and promoting sustainability, rice processing technology underscores the delicate balance between tradition and modernity in agriculture.

As we embrace the future, it is essential to recognize the significant impact that these machines have on food security, economic growth, and the livelihoods of millions. With the continuous evolution of technology, the promise of even greater advancements looms on the horizon, inviting us to imagine a world where rice processing not only meets global demand but also champions environmental stewardship and social responsibility.

In the grand tapestry of agriculture, rice processing machines serve as the threads weaving together history, innovation, and hope. As we savor the grains that nourish us, let us also appreciate the unseen efforts and sophisticated machinery that transform them into the staple foods we cherish. The journey of rice—from field to plate—reminds us of the intricate relationship between mankind and the machines that support our quest for sustenance and prosperity.