Transforming Grains: A Deep Dive into Rice Processing Plants

In the vast tapestry of global agriculture, rice holds a revered position as a staple food for over half of the world’s population. But behind the humble grain lies a complex and intricate world of processing that transforms paddy fields into polished grains ready for your plate. Enter the rice processing plant—a hub of innovation and efficiency where nature’s bounty is meticulously refined through a myriad of stages. From drying and milling to grading and packaging, these facilities embody the delicate balance between tradition and technology. In this article, we embark on a journey through the inner workings of rice processing plants, uncovering the science, artistry, and sustainability that underpin the journey of rice from farm to fork. Join us as we explore the fascinating processes that turn raw grains into the culinary cornerstone that nourishes millions around the globe.

Exploring the Journey of Rice: From Field to Plate

The journey of rice from field to plate is a fascinating tale rich in tradition, labor, and innovation. Each grain has a story that begins in verdant paddies, where farmers nurture the rice crop through careful management of water and soil. This meticulous process involves various steps that transform raw grains into the staple food cherished worldwide. Once harvested, the rice undergoes a series of processes in processing plants that efficiently prepare it for consumption. Key stages in this transformation include:

- Cleaning: Removing impurities and foreign materials.

- Hulling: Separating the husk from the grain.

- milling: Polishing the grain to achieve the desired level of refinement.

- Sorting: Categorizing rice based on size, quality, and color.

After processing, the rice is often packaged for distribution. It is essential to maintain quality and freshness, ensuring that consumers receive the best product possible. Processing plants, equipped with modern technology, utilize numerous machines and processes to ensure efficiency and minimize waste. The tables below illustrate some average processing times and yield percentages for different rice types:

| Rice Type | Average Processing Time (hours) | Yield Percentage (%) |

|---|---|---|

| Long Grain | 3 | 65 |

| Medium Grain | 4 | 70 |

| Short Grain | 4.5 | 75 |

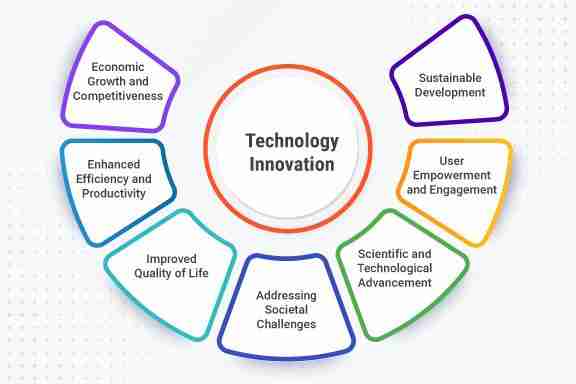

Innovative Technologies in Rice Processing and Their Impact

The rice processing industry is undergoing a remarkable transformation, fueled by innovative technologies that enhance efficiency, reduce waste, and improve product quality. Leading rice processing plants are now implementing cutting-edge solutions such as automatic milling systems, AI-driven quality control, and advanced sorting mechanisms. These technologies not only streamline operations but also ensure that the end product meets the evolving demands of consumers who prioritize both quality and sustainability. With the integration of machine learning algorithms, processors can predict maintenance needs, thereby minimizing downtime and maximizing productivity.

Furthermore, the use of renewable energy sources, such as solar power and biogas, is becoming increasingly prevalent in the rice milling sector. This commitment to sustainability not only lowers operational costs but also significantly reduces the carbon footprint of rice processing plants. Some of the key advancements include:

- Smart drying systems that optimize moisture levels effectively

- Eco-friendly packaging solutions that reduce plastic waste

- Blockchain technology for traceability in the supply chain

Incorporating these technologies contributes to a more sustainable food system that is capable of meeting global rice demands while protecting the environment.

| Technology | Benefits |

|---|---|

| Automatic Milling Systems | Increased efficiency and reduced labor costs |

| AI-Driven Quality Control | Consistent product quality and reduced waste |

| Renewable Energy Sources | Lower operational costs and reduced carbon footprint |

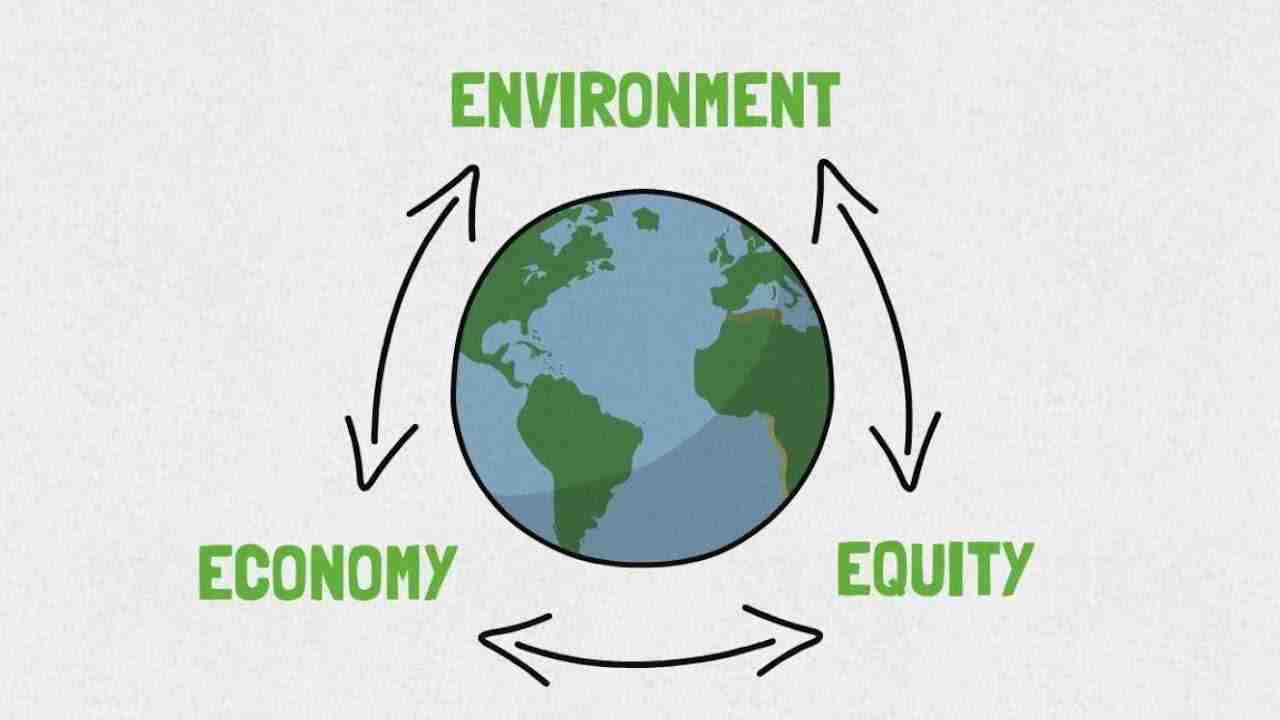

Sustainability Practices in Rice Factories: Balancing Quality and Environment

In the quest for heightened efficiency and product quality, rice factories are increasingly adopting sustainability practices that not only enhance their output but also minimize their environmental footprint. These practices revolve around innovative processing techniques that aim to conserve energy and reduce waste. For example, many factories are now utilizing biomass energy sourced from rice husks and straw, which not only powers their operations but also mitigates greenhouse gas emissions. Furthermore, advancements in water recycling and purification systems allow for the reuse of wastewater in irrigation, ensuring that environmental resources are preserved. A commitment to sustainable sourcing of raw materials, coupled with a focus on ethical labor practices, further embodies the holistic approach necessary for balancing quality with environmental responsibility.

Additionally, the integration of sustainable packaging methods is becoming a significant trend among rice processors. Many companies are transitioning from conventional plastic packaging to biodegradable and recyclable alternatives, thereby reducing plastic waste that often ends up in landfills. This shift is complemented by educating consumers on the importance of sustainable choices, turning eco-friendly packaging into a selling point. The following table illustrates various sustainability initiatives being implemented in rice factories:

| Initiative | Description | Benefit |

|---|---|---|

| Energy Recovery | Using rice husks as a renewable energy source | Reduces reliance on fossil fuels |

| Water Management | Implementing closed-loop water systems | Conserves freshwater and reduces wastewater output |

| Sustainable Packaging | Switching to biodegradable and recyclable materials | Minimizes plastic waste in the environment |

Future Trends in Rice Processing: Adapting to Global Demands

As the global landscape of agriculture evolves, the rice processing industry stands on the precipice of significant change. With increasing demand for quality, sustainability, and efficiency, processors are now focusing on innovative technologies that maximize output while minimizing waste. Key trends include the implementation of smart processing systems that leverage big data and IoT for real-time monitoring, which enhances quality control and reduces operational costs. Additionally, advancements in automation and robotics are transforming traditional workflows, allowing for higher production rates and safer working conditions.

In response to shifting consumer preferences, the sector is also prioritizing sustainability. Many processing plants are now adopting green technologies that utilize renewable energy sources and reduce carbon footprints. Furthermore, the trend towards producing value-added products, such as rice flour and gluten-free options, is gaining traction as consumers seek alternatives aligned with their dietary needs. The integration of traceability systems ensures transparency from field to consumer, reinforcing trust and meeting the demands of an increasingly conscientious market.

| Trend | Description |

|---|---|

| Smart Processing | Utilizes IoT and big data for efficiency and quality control. |

| Automation | Robotics enhance production rates and safety. |

| Sustainability | Adoption of renewable energy technologies to reduce carbon impact. |

| Value-added Products | Focus on gluten-free and health-oriented rice derivatives. |

| Traceability | Ensures transparency from farm to table. |

In Summary

As we conclude this exploration into the intricate world of rice processing plants, it becomes clear that these facilities are not merely factories but vital hubs where tradition meets innovation. The journey from golden paddy to packaged rice is a symphony of engineering, science, and culture, driven by the collective goal of delivering nourishment to countless tables worldwide.

In an era where sustainability is paramount, the advancements in rice processing technologies offer promising solutions to reduce waste and enhance efficiency, ensuring that this staple food continues to play a pivotal role in global diets. Whether through automated machinery or refined milling techniques, each step in the process is a testament to the ingenuity of agricultural advancements.

As we move forward, the challenge lies not just in the mechanism of processing but also in embracing the responsibility that comes with it. By fostering sustainable practices and respecting the heritage of rice cultivation, we can ensure that this beloved grain remains a cornerstone of food security and cultural identity for generations to come.

Thank you for joining us on this deep dive into rice processing plants. May your understanding of this essential element of our food system inspire appreciation for the myriad of processes that transform nature’s bounty into the staple foods we cherish.