Rice – a staple in cuisines worldwide, beloved for its versatility and comforting presence on our plates. But have you ever stopped to wonder about the journey this humble grain takes before it reaches your kitchen? Join us as we step inside a modern processing plant to dive into the art of perfecting parboiled rice. From intricate machines to skilled technicians, discover the meticulous process behind turning raw rice into the fluffy, aromatic grains we all know and love. Uncover the secrets of this ancient practice, as we explore the intersection of tradition and innovation in the world of rice processing.

Introduction: Exploring the Science Behind Parboiled Rice

Step into the world of parboiled rice, where science meets culinary perfection. At the heart of a modern processing plant, the art of perfecting parboiled rice comes to life through a meticulous process that combines tradition with innovation. From the initial soaking stage to the final steaming process, every step plays a crucial role in ensuring the quality and consistency of the final product.

**Experience the journey of each grain as it undergoes a transformation like no other. Through cutting-edge technology and time-honored techniques, parboiled rice emerges as a versatile and nutritious staple that delights taste buds around the globe. Discover the science behind parboiled rice and gain a new appreciation for this culinary treasure that has been cherished for generations.**

The Production Process: From Paddy to Perfectly Parboiled Rice

In a modern processing plant dedicated to perfecting parboiled rice, the production process begins with carefully selected paddy grains sourced from local farmers. These high-quality grains are then cleaned and sorted to remove any impurities or foreign materials before being transferred to the soaking tanks.

Once in the soaking tanks, the paddy grains undergo a meticulous process of soaking, steaming, and drying to ensure that each grain is perfectly parboiled. The grains are then carefully milled to remove the outer husk, bran, and germ, leaving behind only the nutritious and delicious parboiled rice ready for packaging and distribution.

Quality Control Measures: Ensuring Consistency and Superiority

The Art of Perfecting Parboiled Rice: Inside a Modern Processing Plant

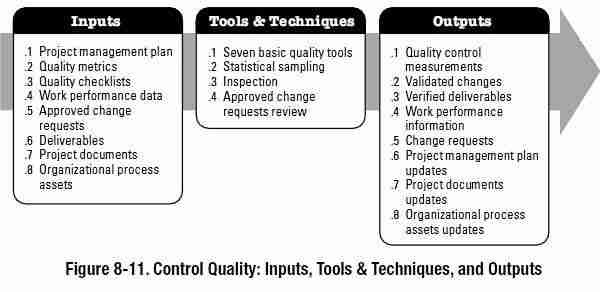

At our state-of-the-art processing plant, we have implemented stringent quality control measures to ensure that every batch of parboiled rice that leaves our facility is of the highest standard. Our commitment to consistency and superiority begins with the selection of the finest raw ingredients sourced from trusted suppliers. Each batch of rice is carefully inspected for any impurities or defects before undergoing the parboiling process.

Once the rice has been parboiled to perfection, it goes through a series of quality checks to ensure that it meets our strict standards. Our dedicated team of quality control experts conducts thorough inspections, checking for factors such as moisture content, texture, and aroma. Any rice that does not meet our criteria is rejected, ensuring that only the best quality rice reaches our customers’ tables.

Innovative Technologies: The Future of Parboiled Rice Processing Plants

Enhancing the efficiency and quality of parboiled rice processing plants is crucial for meeting the growing demand for this staple food product. With the advancement of innovative technologies, modern processing plants are revolutionizing the way parboiled rice is produced. From automated systems to state-of-the-art machinery, these plants are ensuring a more streamlined and precise production process.

One of the key technologies shaping the future of parboiled rice processing plants is the use of computerized systems that monitor every step of the production process. These systems ensure consistency in temperature control, moisture levels, and cooking times, resulting in perfectly parboiled rice every time. Additionally, advanced milling machines and optical sorters are enhancing the quality of the final product by removing impurities and ensuring uniform grain size. With these cutting-edge technologies, modern processing plants are setting new standards for the parboiled rice industry.

Key Takeaways

As we’ve delved into the intricate process of perfecting parboiled rice within a modern processing plant, it’s clear that there is a true artistry behind this seemingly simple grain. From meticulous soaking and steaming to precise drying and milling, every step is crucial in achieving that perfect fluffy texture and nutty flavor.

In a world where convenience often trumps quality, it’s refreshing to see the dedication and craftsmanship that goes into producing this staple food. So, the next time you enjoy a plate of perfectly cooked parboiled rice, remember the intricate journey it took to reach your table.

And as we continue to appreciate the art of food processing, let’s not forget the hardworking individuals behind the scenes who strive for perfection with every batch they produce. Here’s to the unsung heroes of the modern processing plant, mastering the art of parboiled rice one grain at a time. Cheers to the artistry of food production!