Step into the fascinating world of rice processing, where humble grains from the fields are transformed into a staple that feeds millions around the globe. Join us as we take a journey from the muddy paddies to the bustling factories, exploring the intricate process that brings that simple grain of rice to your table. Get ready to uncover the secrets and the science behind this essential food production industry. Welcome to the world of rice processing – where tradition meets innovation.

Exploring the Journey of Rice from Harvesting to Milling

Once the rice is harvested from the fields, it goes through a series of processes before it’s ready for consumption. The first step in the journey of rice processing is threshing, where the grains are separated from the straw. This is typically done using a machine that beats the rice stalks to loosen the grains.

Next, the rice undergoes the process of milling, where the outer layers of the grain are removed to reveal the white rice inside. This is an essential step to produce the polished rice that we are familiar with. The milling process involves removing the husk, bran, and germ layers, leaving behind the white rice kernels that we see on our plates. The final product is then ready to be packaged and distributed to consumers worldwide.

Innovative Technologies Revolutionizing Rice Processing

Rice processing has undergone a phenomenal transformation thanks to cutting-edge technologies that streamline operations from the field to the factory. **Artificial Intelligence (AI)** is now being used to predict crop yield, optimize planting patterns, and detect diseases in rice plants. This data-driven approach helps farmers make informed decisions, resulting in higher productivity and better quality rice.

**Robotics** have also made their mark in rice processing, automating tasks such as harvesting, threshing, and sorting. These robots work efficiently and accurately, reducing labor costs and improving overall efficiency. Additionally, **Near Infrared (NIR) spectroscopy** is being utilized to analyze the chemical composition of rice grains, ensuring that they meet quality standards before being processed further. These innovative technologies are revolutionizing the rice industry, making the process more sustainable and profitable for farmers and processors alike.

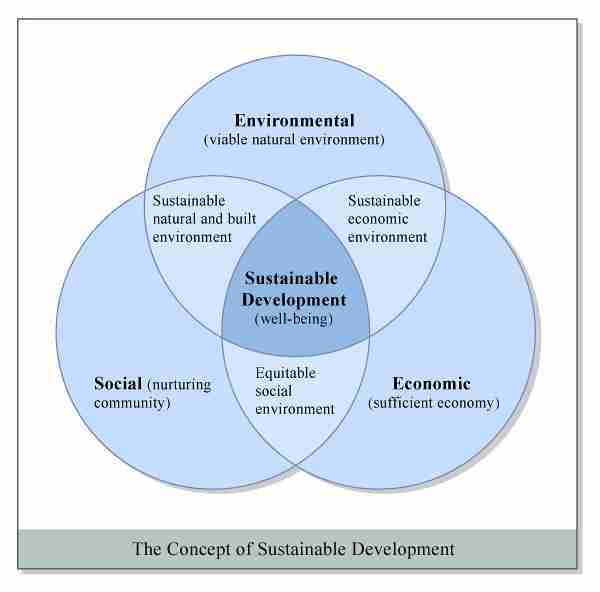

Sustainable Practices for Efficient Rice Processing

When it comes to sustainable practices in rice processing, efficiency is key. By implementing innovative technologies and best practices, rice processing facilities can significantly reduce their environmental impact while increasing productivity. One way to achieve this is by optimizing water usage throughout the processing stages. From cleaning and soaking to boiling and steaming, **efficient water management** can not only save valuable resources but also minimize wastewater discharge.

Another important aspect of sustainable rice processing is energy efficiency. By utilizing **renewable energy sources** such as solar power or biomass, processing plants can decrease their reliance on fossil fuels and reduce greenhouse gas emissions. Additionally, implementing **energy-saving equipment** and making use of waste heat can further enhance the overall efficiency of the processing operations.

Quality Control Measures in Rice Processing Facilities

When it comes to ensuring the quality of rice products, processing facilities implement stringent measures throughout the entire production process. One key aspect of quality control in these facilities is the inspection of incoming raw materials. Before any rice can be processed, it undergoes thorough inspection to check for any impurities or defects that could affect the final product.

Once the rice is deemed suitable for processing, it goes through a series of cleaning and milling processes to remove husks, bran, and other unwanted particles. Quality control measures are also implemented during these stages to ensure that only the finest grains are selected for packaging. In addition, high-tech machinery and equipment are utilized to maintain consistent quality standards and efficiency in the production line.

Insights and Conclusions

As we conclude our journey through the fascinating world of rice processing, we have gained a deeper understanding of the intricate process that transforms humble grains from the field into the staple food that feeds millions around the world. From the meticulous farming methods to the advanced technology used in the factories, every step plays a crucial role in bringing rice to our tables. Next time you enjoy a steaming bowl of rice, take a moment to appreciate the journey it has taken to reach you. The story of rice is truly a tale of resilience, innovation, and the enduring bond between nature and mankind. Thank you for joining us on this enlightening exploration. Until next time, may your rice always be plentiful and delicious.