Unlocking Potential: The Evolution of Rice Milling Machines

In the heart of agricultural innovation lies a humble yet transformative tool: the rice milling machine. From modest beginnings rooted in ancient traditions to the cutting-edge technology we see today, these machines have undergone a remarkable evolution that reflects both advancements in engineering and the shifting demands of a global market. As rice remains a staple food for billions, the quest for efficiency, quality, and sustainability has propelled the development of milling techniques into uncharted territories. This article delves into the rich history of rice milling machines, exploring how they have adapted over time to unlock the potential of this vital grain, enhance the livelihoods of farmers, and feed a growing population. Join us on a journey through the mechanics and innovations that have shaped one of the oldest yet most essential industries in the world.

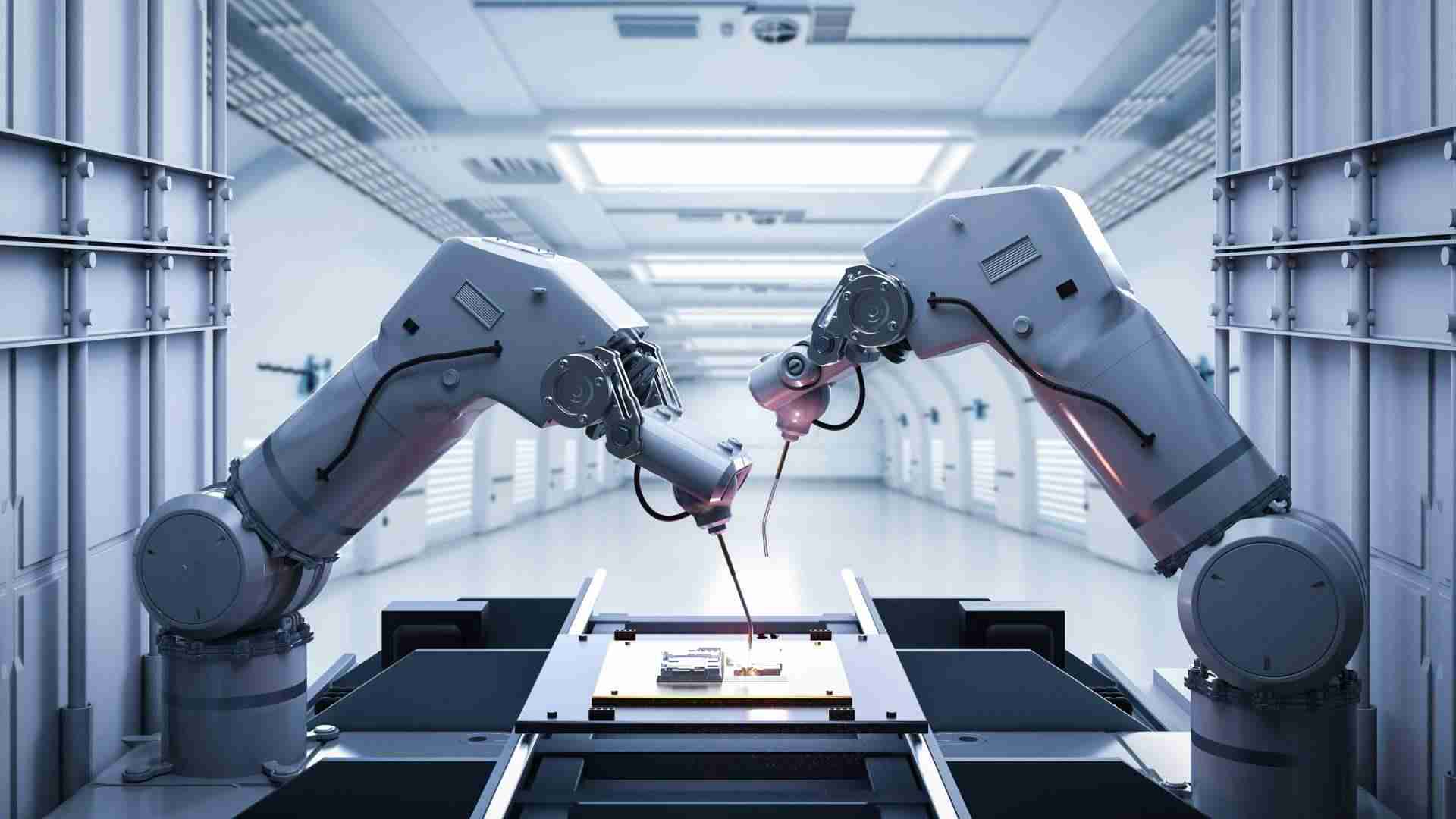

Advancements in Technology Driving Modern Rice Milling Solutions

The modern rice milling industry has undergone a remarkable transformation, driven by cutting-edge technologies that enhance efficiency and output quality. Automation plays a pivotal role in this evolution, with smart sensors and IoT integration enabling real-time monitoring of milling processes. This not only ensures precision in grain processing but also minimizes human error. With applications like machine learning, these systems can analyze vast amounts of data to optimize settings, predict maintenance needs, and improve overall productivity. As a result, rice milling operations are now capable of achieving consistent quality while significantly reducing waste and energy consumption.

Furthermore, the incorporation of AI-driven technologies has allowed for innovative features such as automatic grain sorting and contamination detection. These advancements not only enhance the final product but also prioritize safety and quality. Consider, for example, how modern mills utilize advanced husking and polishing methods which retain the nutritional value of rice while improving its shelf life. Below is a quick overview of some of these transformative technologies:

| Technology | Benefit |

|---|---|

| IoT Integration | Real-time monitoring and enhanced control |

| Machine Learning | Predictive maintenance and optimized performance |

| AI Sorting Systems | Improved quality control and contamination detection |

| Advanced Polishing Techniques | Retained nutritional value and extended shelf life |

The Impact of Automation on Efficiency and Productivity

The advent of automation has revolutionized the rice milling industry, significantly enhancing the efficiency and productivity of processing operations. By integrating advanced machinery and technology, rice mills can now operate at unprecedented speeds, reducing the time required for milling while simultaneously increasing the quality of the end product. Key benefits include:

- Reduced Labor Costs: Automation minimizes the need for manual intervention, allowing staff to focus on oversight rather than repetitive tasks.

- Enhanced Precision: Automated systems ensure uniformity in milling, resulting in a better-quality rice product.

- Increased Throughput: Mills can process larger quantities of rice at a significantly faster rate, meeting the demands of larger markets.

The introduction of sophisticated milling equipment, such as automated sorters and huskers, has also led to a decrease in production waste. Modern machines utilize sensors and AI to optimize every stage of the process. This not only maximizes output but also contributes to sustainable practices within the industry. The following table illustrates a comparison between traditional and automated rice milling processes:

| Aspect | Traditional Milling | Automated Milling |

|---|---|---|

| Processing Speed | Slow | Fast |

| Labor Requirement | High | Low |

| Quality Control | Manual | Automated |

| Sustainability | Less Efficient | More Efficient |

This transformative technology not only uplifts operational benchmarks but also pushes the boundaries of what is possible in food production, setting a new standard that blends innovation with efficiency.

Sustainable Practices in Rice Milling for a Greener Future

As the demand for rice continues to rise globally, the need for sustainable practices in rice milling has become increasingly crucial. Innovative technologies that enhance efficiency while minimizing environmental impact are emerging as vital components of modern milling operations. These advancements focus on reducing waste, optimizing energy consumption, and ensuring resource conservation. Key practices include:

- Water Recycling: Implementing closed-loop systems to recycle and reuse water during the milling process, significantly reducing the total water footprint.

- Biomass Utilization: Transforming rice husks and other by-products into bioenergy, thus minimizing waste and generating sustainable energy sources for milling operations.

- Energy-efficient Equipment: Investing in insulated and energy-efficient milling machines that consume less energy without compromising on performance.

Moreover, the integration of digital technologies assists in monitoring and enhancing production processes. For instance, the use of data analytics allows millers to track energy consumption and waste generation, making it easier to identify areas for improvement. Additionally, the shift towards eco-friendly packaging solutions helps reduce the environmental footprint associated with rice distribution. Below is a comparison of traditional versus sustainable milling practices:

| Aspect | Traditional Practices | Sustainable Practices |

|---|---|---|

| Water Usage | High water wastage | Recycled water systems |

| Energy Consumption | High energy costs | Energy-efficient machinery |

| Waste Management | Inadequate disposal | Biomass conversion |

Future Trends Shaping the Rice Milling Industry and Its Potential

The rice milling industry is on the cusp of a technological transformation, driven by advancements that promise to elevate efficiency and sustainability. Automation is at the forefront, as intelligent milling systems integrate AI and machine learning to optimize processes. Modern machines are designed to analyze grain quality, adjust settings in real-time, and minimize waste. This evolution not only improves yield but also enhances the overall quality of rice, catering to an increasingly discerning market. Additionally, sustainability measures such as energy-efficient designs and eco-friendly materials are becoming a staple, as mills strive to reduce their carbon footprint and meet regulatory demands.

Furthermore, the rise of smart technologies is reshaping how mills operate. With the introduction of IoT components, rice milling machines can now collect vast amounts of data, allowing for predictive maintenance and remote monitoring. These insights empower mill owners to maximize uptime and lower operational costs, creating a more resilient supply chain. The integration of blockchain technology is also gaining traction, promising transparency in sourcing and distribution. As consumers show greater interest in ethically produced goods, tracing the journey of rice from field to plate can enhance brand loyalty and trust. As these trends unfold, they are setting the stage for a more innovative and responsive rice milling industry.

| Trends | Impact |

|---|---|

| Automation | Increased efficiency and product quality |

| Sustainability | Reduced environmental impact |

| Smart Technologies | Enhanced data-driven decision-making |

| Blockchain | Improved transparency and consumer trust |

In Summary

As we conclude our exploration into the remarkable evolution of rice milling machines, it becomes clear that these innovations are more than mere tools; they are catalysts for transformation in the agricultural sphere. From the rudimentary methods of yesteryears to the sophisticated machinery of today, the journey of rice milling reflects a broader narrative of technological advancement and sustainability.

Each enhancement in milling technology not only serves to optimize efficiency and quality but also empowers farmers and communities, unlocking potential that extends far beyond the harvest. As we look to the future, it is essential to continue supporting and investing in research and development, ensuring that these machines not only keep pace with the growing demands of the global market but also contribute to a more equitable food system.

The story of rice milling machines is one of resilience, innovation, and opportunity—an ongoing saga that invites us to envision a world where technology uplifts agricultural practices and nourishes a growing population. With every grain of rice processed, we are reminded of the intricate connections between heritage, industry, and progress. As we continue to unlock potential, we do so not just for ourselves, but for generations to come.