In a world where efficiency is paramount, the pursuit of optimizing agricultural processes has never been more critical. Among the myriad of crops that sustain populations globally, rice stands out not only as a staple food but also as a significant economic driver. At the heart of rice production lies the milling process, a transformative stage that converts paddy into the polished grains we enjoy on our plates. This is where rice milling machines play an indispensable role. In this comprehensive guide, we delve into the world of rice milling machines, exploring their evolution, types, and advancements that unlock unprecedented efficiency. Whether you are a seasoned farmer, a mill operator, or an entrepreneur looking to invest in this essential machinery, we aim to equip you with valuable insights and practical advice to navigate the complexities of rice milling. Join us as we unlock the secrets of this vital industry and uncover how modern technology continues to reshape the way we process one of the world’s most cherished grains.

Understanding the Fundamentals of Rice Milling Technology

Rice milling technology is a sophisticated process designed to maximize the efficiency of converting raw paddy into high-quality rice. At its core, the technology involves a series of meticulously engineered steps, each tailored to remove the hull from the kernel while preserving its integrity. These steps typically include dehusking, grading, and polishing. Dehusking utilizes a combination of mechanical and air pressure systems to separate the outer husk, while grading sorts the rice by size and quality to ensure uniformity. Polishing then enhances the appearance of the finished product, giving it that glossy sheen that consumers often seek.

Understanding the machinery involved in rice milling is essential for anyone looking to optimize production. Key components of milling systems often include husk removers, rice polishers, and de-stoners. These versatile machines not only improve the quality of the rice but also significantly reduce waste, contributing to a more sustainable process overall. Below is a summary table highlighting some essential rice milling equipment and their functions:

| Equipment | Function |

|---|---|

| Husk Remover | Removes the outer husk from paddy. |

| Rice Polisher | Enhances surface quality and removes impurities. |

| De-stoner | Separates stones and foreign materials from the rice. |

Exploring Different Types of Rice Milling Machines

When it comes to rice milling, understanding the different types of machines available can greatly impact efficiency and quality. There are primarily two main categories of rice milling machines: traditional milling machines and modern automated mills. Traditional mills typically operate with a simpler mechanism and are often more affordable, making them ideal for small-scale farmers or communities. In contrast, modern automated milling machines offer higher throughput and efficiency, reducing labor costs while ensuring uniformity in rice quality. These advanced machines incorporate technology such as pneumatic conveying and color sorting systems to ensure optimal output and minimize wastage.

Each type of milling machine comes with its own set of features and advantages. Below is a quick comparison of the most common rice milling machines:

| Type | Key Features | Ideal For |

|---|---|---|

| Traditional Mill |

|

Small farms and local markets |

| Automated Mill |

|

Commercial use and large-scale production |

The choice between these machines ultimately depends on your specific requirements, budget, and scale of operations. While traditional mills are excellent for those just starting or operating at a smaller scale, modern automated machines are better suited for those looking to maximize production and efficiency. Understanding the features and benefits of each can empower you to make an informed decision that aligns with your milling goals.

Maximizing Productivity: Key Features to Look For

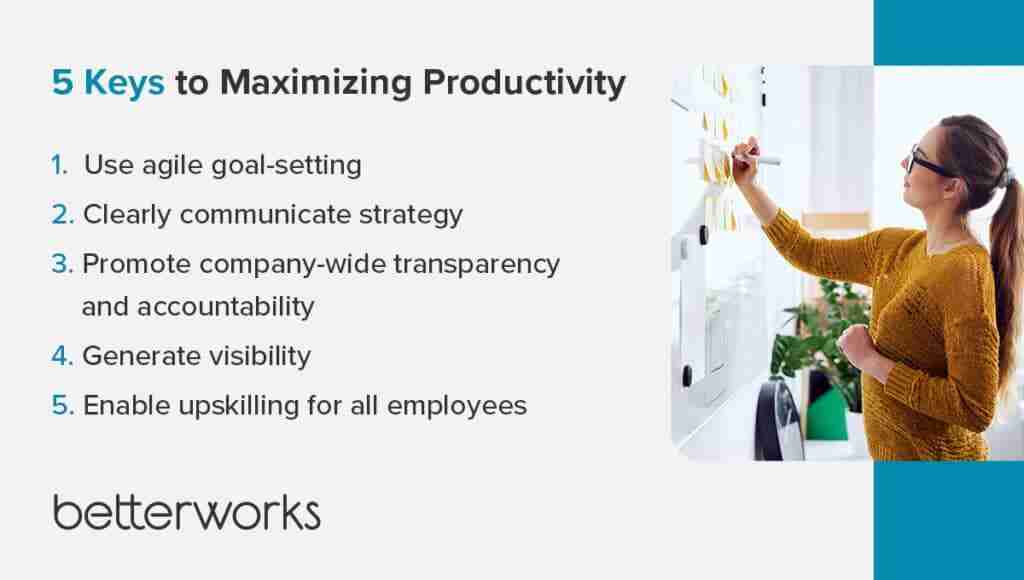

When selecting a rice milling machine, several essential features can significantly enhance your productivity. Automation stands out as a crucial element; machines equipped with automatic control systems allow for precise adjustments to milling parameters, ensuring consistent results with minimal manual intervention. Additionally, energy efficiency can substantially lower operational costs, so consider models that are designed to minimize power consumption while maximizing output. Another key aspect is the machine’s capacity and throughput, which should align with your production needs. A higher throughput can reduce processing time, enabling you to meet demand more effectively.

Furthermore, the versatility of the milling machine should not be overlooked. Machines that offer multiple milling options can cater to various rice grades and processing preferences, thus expanding your potential market. Ease of cleaning and maintenance is also paramount; machines that are designed for straightforward disassembly simplify the upkeep process, resulting in less downtime. integrated monitoring systems can provide real-time feedback on operational parameters, allowing for proactive adjustments and ensuring an uninterrupted milling process.

Maintenance and Troubleshooting Tips for Optimal Performance

To ensure that your rice milling machine operates at peak efficiency, regular maintenance is crucial. Scheduling routine checks on the machine’s key components can significantly reduce the likelihood of unexpected downtimes. Focus on the following areas for maintenance:

- Cleaning: Remove residual rice husks and dust regularly to avoid clogging.

- Lubrication: Use the appropriate lubricants for bearings and moving parts as specified in the manual.

- Calibration: Regularly calibrate the machine settings to maintain accurate milling quality.

- Inspection: Check belts, pulleys, and blades for wear and tear; replace when necessary.

Troubleshooting common issues can help minimize downtime and enhance the overall performance of your milling operation. If you encounter problems, consider the following tips:

| Issue | Possible Causes | Solutions |

|---|---|---|

| Poor milling quality | Incorrect settings, dull blades | Adjust settings, sharpen or replace blades |

| Unusual noise | Loose components, lubrication issues | Tighten components, lubricate parts |

| Machine overheating | Overloading, poor ventilation | Reduce load, ensure proper airflow |

In Conclusion

As we conclude our exploration of rice milling machines, we hope this guide has illuminated the intricate balance of tradition and technology that defines modern rice processing. These machines are not merely industrial tools; they represent a bridge between the agrarian roots of rice cultivation and the sophisticated demands of today’s food industry. By understanding their functionality, maintenance, and impact on yield, you are now equipped to make informed decisions that enhance productivity and sustainability in rice milling.

As the global population continues to grow, the need for efficient food production becomes more critical. Embracing advancements in rice milling technology can ensure that we meet this challenge head-on, creating a future where quality grain is accessible to all. Whether you’re a seasoned entrepreneur or just stepping into the world of rice milling, remember that every grain counts in the pursuit of efficiency, quality, and sustainability.

Thank you for joining us on this journey. May your endeavors in rice milling lead to not only increased efficiency but also a lasting impact on the communities you serve. Happy milling!