In the vast tapestry of agricultural innovation, few advancements have been as transformative as the introduction of industrial milling machines in rice production. Rice, a staple food for over half of the world’s population, has long been cultivated using traditional methods that, while effective, can be labor-intensive and time-consuming. However, the advent of modern milling technology is not just a shift in machinery; it represents a paradigm change in how we think about food sustainability, efficiency, and economic viability. From improving the quality of milled grains to increasing output while reducing waste, industrial milling machines are redefining the landscape of rice production. This article delves into the mechanics of these machines, the benefits they bring to farmers and consumers alike, and the potential they hold for the future of global food security. Join us as we explore how these innovations are not only revolutionizing rice production but also paving the way for smarter, more sustainable agricultural practices.

Innovative Technologies Driving Modern Rice Milling Efficiency

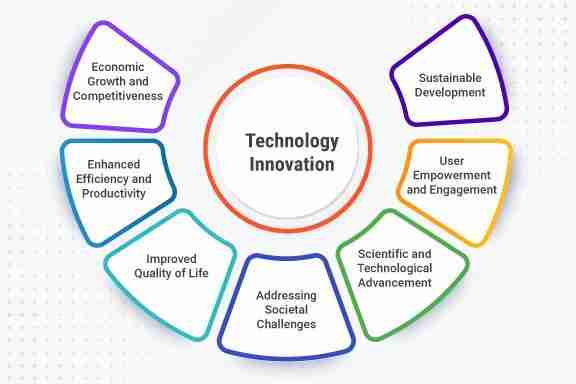

Recent advancements in milling technology have significantly transformed the rice production landscape, paving the way for enhanced operational performance and product quality. Key innovations such as automated process controls, smart sensors, and data analytics not only optimize milling operations but also ensure consistent output. With the integration of these technologies, millers can monitor real-time data regarding moisture levels, temperature, and milling efficiency, leading to quicker adjustments and reduced waste. Furthermore, energy-efficient machinery reduces operational costs, aligning with sustainability goals while improving overall productivity.

Among the standout technologies in modern rice milling are high-capacity milling machines and pneumatic conveying systems. These advanced systems enable the processing of larger batches of rice while maintaining the integrity of the grain. Additionally, the introduction of digital tracking systems allows millers to trace the journey of their rice from the paddy to the finished product, ensuring quality assurance and transparency throughout the supply chain. Below is a simple breakdown of these essential technologies and their key benefits:

| Technology | Benefits |

|---|---|

| Automated Process Controls | Enhances precision and reduces manual labor |

| Smart Sensors | Real-time monitoring for optimal performance |

| High-Capacity Milling Machines | Increases output without compromising quality |

| Pneumatic Conveying Systems | Saves time and reduces grain breakage |

| Digital Tracking Systems | Ensures traceability and quality assurance |

Sustainable Practices in Industrial Rice Processing

In the quest for efficiency and sustainability within the rice processing industry, several innovative practices have emerged that not only optimize production but also minimize environmental impact. By implementing energy-efficient technologies, mills can drastically reduce their carbon footprint. Techniques such as heat recovery systems recycle excess heat produced during milling, while solar energy installations harness natural resources to power operations. Other sustainable measures include the use of biodegradable packaging materials that replace plastic, significantly contributing to waste reduction.

Moreover, adopting water conservation techniques is critical in rice processing, given the crop’s high water demand. Implementing closed-loop water systems enables the reuse and recycling of water, ensuring minimal wastage. Additionally, integrating crop residue management practices helps enhance soil health and reduces reliance on chemical fertilizers. To highlight the benefits of these practices, below is a simple comparison table showcasing traditional versus sustainable processing methods:

| Aspect | Traditional Methods | Sustainable Practices |

|---|---|---|

| Energy Consumption | High | Reduced |

| Waste Generation | Significant | Minimized |

| Water Usage | Extensive | Efficient |

| Soil Impact | Degradation | Enhancement |

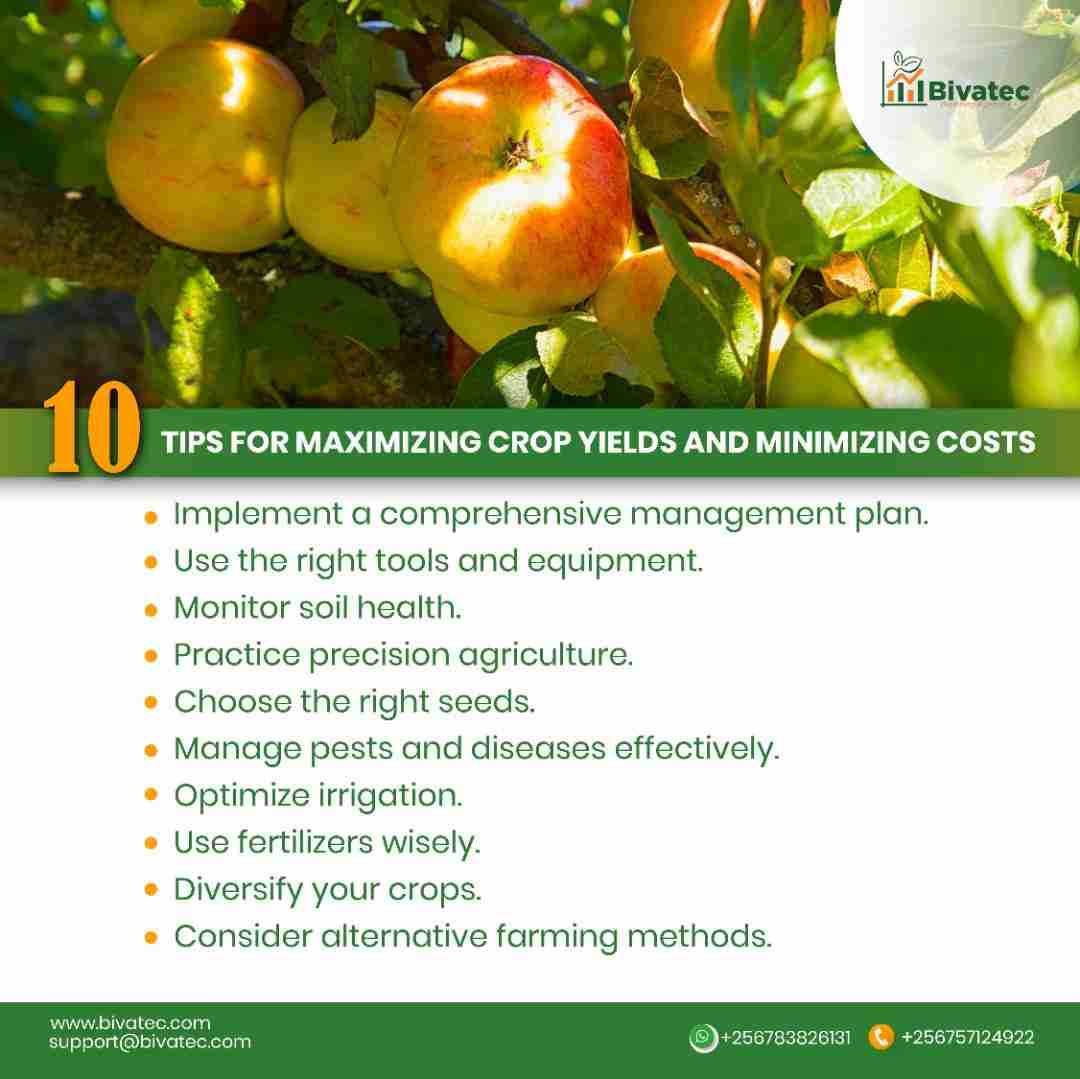

Maximizing Yield: Maintenance and Operation Insights for Mill Owners

To ensure optimal output and longevity of industrial milling machines, mill owners must engage in proactive maintenance practices. Regular checks and preventive measures can significantly enhance performance, reduce downtime, and prevent costly repairs. Key maintenance tasks include:

- Regular Lubrication: Keep all moving parts lubricated to minimize friction and wear.

- Hygiene Scrubbing: Maintain a clean milling environment to avoid contamination that can affect rice quality.

- Alignment Monitoring: Ensure that machinery is properly aligned to avoid uneven wear.

- Component Inspection: Frequently inspect and replace worn or damaged components to maintain efficiency.

In addition to routine maintenance, effective operation strategies are essential for maximizing yield during production. Implementing a systematic approach to the operation of milling machines can lead to consistent output. Consider the following operational insights:

| Operational Insight | Description |

|---|---|

| Feed Rate Optimization | Adjust the feed rate to balance the load on the machine, improving efficiency. |

| Moisture Level Management | Monitor and control moisture levels to ensure optimal milling conditions. |

| Staff Training | Invest in training operators to enhance skills and operational understanding. |

| Performance Monitoring | Use data analytics to track performance metrics and identify areas for improvement. |

Empowering Farmers: The Economic Impact of Advanced Milling Solutions

Advanced milling solutions have the potential to significantly uplift the agricultural landscape by directly enhancing the productivity and profitability of farmers. The integration of industrial milling machines facilitates greater efficiency in processing, which leads to a marked improvement in the quality of the final rice product. By adopting innovative technologies, farmers can refine their production processes, leading to:

- Increased Yield: Higher throughput capabilities allow farmers to mill larger quantities of rice in shorter timeframes.

- Cost Reduction: Improved efficiency lowers operational costs, enabling farmers to allocate funds toward other critical areas of their business.

- Quality Enhancement: Advanced milling technology results in better rice texture and taste, increasing marketability.

Moreover, the economic benefits extend beyond the individual farmer; they ripple through entire communities, enhancing rural economies. By boosting local production, there can be a surge in job opportunities related to rice milling and distribution. Here’s a brief overview of potential impacts:

| Impact Area | Effect |

|---|---|

| Local Employment | Creation of milling and processing jobs |

| Community Development | Increased investments in local infrastructure |

| Market Access | Improved supply chains connect farmers with broader markets |

This synergy not only enhances the income among farmers but also fosters a more sustainable agricultural ecosystem, which is vital for long-term food security and economic resilience in farming regions.

To Conclude

As we draw the curtain on our exploration of the transformative journey within rice production, it is clear that the industrial milling machine stands at the forefront of this agricultural revolution. With its ability to enhance efficiency, preserve quality, and meet the demands of an ever-growing global population, this technology is not merely a piece of equipment but a catalyst for change in the rice sector. As farmers embrace innovation and push the boundaries of traditional practices, the potential for sustainable growth and food security becomes increasingly attainable. The future of rice production, bolstered by these advancements, promises not only to improve livelihoods but also to nourish the world. In the grand tapestry of agricultural evolution, the industrial milling machine is a thread that weaves together progress, sustainability, and hope for generations to come. Let us continue to watch and support this pivotal chapter in the story of food production as it unfolds.