In the ever-evolving landscape of agricultural technology, the spotlight is now shining brightly on a remarkable innovation transforming rice processing: combined rice milling machines. As global demand for sustainable and efficient food production escalates, so too does the need for equipment that can keep pace with these demands. Gone are the days of lengthy milling processes and bulky machinery that occupies valuable space and resources. Enter the combined rice milling machine—a marvel of engineering that seamlessly integrates multiple milling functions into a single, compact unit. This article delves into the rise of these machines, examining how they are redefining efficiency in rice production, enhancing output, and paving the way for a more streamlined future in agribusiness. Join us as we explore the intricacies, benefits, and technological advancements that position combined rice milling machines at the forefront of modern agriculture.

Innovative Technology Driving Enhanced Rice Production

The advent of cutting-edge technology in agriculture has revolutionized rice production, making it not only more efficient but also more sustainable. Combined rice milling machines exemplify this innovation by integrating multiple processes that traditionally required separate machinery. By streamlining operations—from threshing to milling—these machines significantly reduce labor costs and processing time, allowing farmers to redirect their efforts toward improving overall crop yield and quality. The adoption of such technology helps to mitigate the challenges posed by labor shortages and fluctuating market demands, ensuring that rice can be processed swiftly and effectively.

Moreover, these machines come equipped with smart features that enhance their functionality. Equipped with sensors and monitoring systems, combined milling machines optimize the milling process by providing real-time feedback on performance, moisture levels, and grain quality. This integration not only minimizes losses but also improves the nutritional value of the rice produced. The following benefits highlight the transformative impact of this technology:

- Increased Efficiency: Reduces time taken from harvesting to milling.

- Cost-effective: Lower labor and operational costs.

- Quality Assurance: Enhances the quality of the final product.

Understanding the Operational Advantages of Combined Rice Milling Machines

Combined rice milling machines offer a range of operational advantages that redefine efficiency in the rice processing sector. One notable benefit is their space-saving design, which integrates multiple milling processes into a single unit. This minimizes the need for a sprawling setup and reduces the associated costs. Additionally, these machines utilize advanced technology that enables higher processing speed, allowing millers to maximize output within a shorter timeframe. With the ability to handle different grain sizes and compositions seamlessly, these machines enhance versatility, meeting the evolving demands of modern rice production.

Moreover, the reduction in labor costs is a significant operational advantage. By implementing combined milling solutions, establishments can operate with fewer personnel while still achieving optimal productivity. The automation aspects of these machines also contribute to maintaining consistent quality, reducing the likelihood of human error during milling operations. An added layer of technical support and reduced downtime significantly enhance productivity, making it easier for producers to maintain quality standards across batches. Notably, the integration of eco-friendly technologies further establishes these machines as a pivotal investment for sustainable farming practices.

Best Practices for Implementing Combined Milling Solutions in Your Facility

Implementing combined milling solutions successfully requires a blend of strategic planning and operational flexibility. Key considerations include assessing your facility’s needs and existing workflows to identify the most appropriate machine configuration. Integration is paramount; aligning new machinery with current processes can enhance productivity and minimize downtime. Furthermore, it’s essential to invest in appropriate staff training to ensure operators can maximize the capabilities of the combined milling systems. This could involve:

- Comprehensive training on the operational nuances of combined machines

- Regular maintenance workshops to keep machinery in optimal condition

- Encouraging feedback from operators to refine processes continuously

Equally important is the establishment of a reliable supply chain for raw materials and replacement parts. Evaluating vendor relationships for quality and service ensures that your milling operation remains smooth and efficient. Additionally, adopting a data-driven approach can help monitor performance metrics and drive improvements. Consider utilizing technology for:

- Real-time monitoring of machine performance

- Evaluating quality control metrics

- Forecasting maintenance needs based on usage data

Here’s a simple table illustrating factors to consider for optimal milling performance:

| Factor | Best Practice |

|---|---|

| Machine Calibration | Regularly calibrate machines per manufacturer guidelines |

| Maintenance Schedule | Implement a proactive maintenance routine |

| Operator Feedback | Conduct regular surveys to capture operator insights |

Future Trends: How Combined Rice Milling Machines Will Shape the Industry

The evolution of combined rice milling machines is set to revolutionize the rice processing industry, blending previously segregated functions into a seamless operation. These advanced systems integrate milling, polishing, and sorting processes, significantly reducing the workspace required while optimizing production efficiency. The shift towards these multifunctional machines not only enhances productivity but also offers manufacturers the ability to rapidly adapt to varying market demands, thus ensuring a competitive edge. The potential for energy cost savings and reduced labor requirements further bolsters the appeal of these machines to modern rice mill operators.

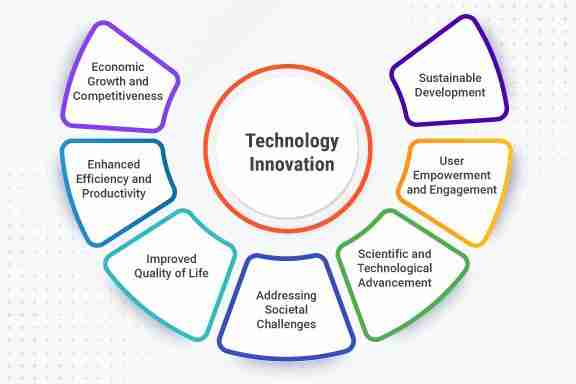

As the demand for high-quality rice continues to rise globally, the role of technology innovation will be pivotal. Key trends shaping this future include:

- Automation and Smart Technologies: Integration of IoT and AI will enable real-time monitoring and data analysis, improving decision-making.

- Customization: Machines designed for specific rice varieties or local preferences will cater to niche markets more effectively.

- Sustainability: The push towards eco-friendly practices will lead to the development of machines that minimize waste and reduce carbon footprints.

Furthermore, manufacturers are likely to invest in research and development to enhance machine resilience and versatility. As a result, we may witness:

| Feature | Benefit |

|---|---|

| Modular Designs | Easy upgrades and maintenance |

| Energy-efficient Motors | Lower operational costs |

| Advanced Sorting Mechanisms | Improved quality control |

In essence, the future of rice milling is leaning towards innovation that prioritizes both efficiency and sustainability, fundamentally altering how the industry meets consumer needs.

In Summary

In a world where innovation meets necessity, combined rice milling machines stand at the forefront of agricultural advancement. As we have explored, these multifunctional marvels not only streamline milling processes but also elevate the quality of the end product and enhance overall productivity. With their capacity to integrate various operations—from husking to polishing—these machines are redefining efficiency in the rice industry, ensuring that farmers and millers can meet the demands of a growing market sustainably.

As we continue to navigate the complexities of modern agriculture, the role of technology in optimizing food production becomes ever more crucial. The rise of combined rice milling machines is not merely a trend; it signals a shift towards smarter, more efficient practices that can sustain our global food supply. We are witnessing a pivotal moment where less truly becomes more—less waste, less energy expenditure, and ultimately, less stress on our planet.

As we step into the future, let us embrace these innovations, learn from their implications, and consider how we might further redefine efficiency in other sectors. The journey does not end here; it’s just the beginning of a new chapter in agricultural technology. Who knows what possibilities lie ahead as we continue to blend tradition with innovation? The future of rice milling—like the grains it processes—holds immense potential for growth.