In the quiet embrace of rural landscapes and bustling industrial hubs alike, rice mills stand as the unsung heroes of grain processing. These vital establishments, often overlooked, play a crucial role in transforming raw paddy into the polished grains that grace our tables. Inside the World of Rice Mills: The Heart of Grain Processing invites readers on a journey through the intricate machinery and age-old traditions that define this industry. From the rhythmic hum of milling equipment to the fragrant aroma of freshly milled rice, we will explore the delicate balance of technology and craftsmanship that fuels one of the world’s most essential food sources. Join us as we delve into the operations, challenges, and innovations that keep this thriving sector at the core of global food production.

Understanding the Rice Milling Process from Field to Table

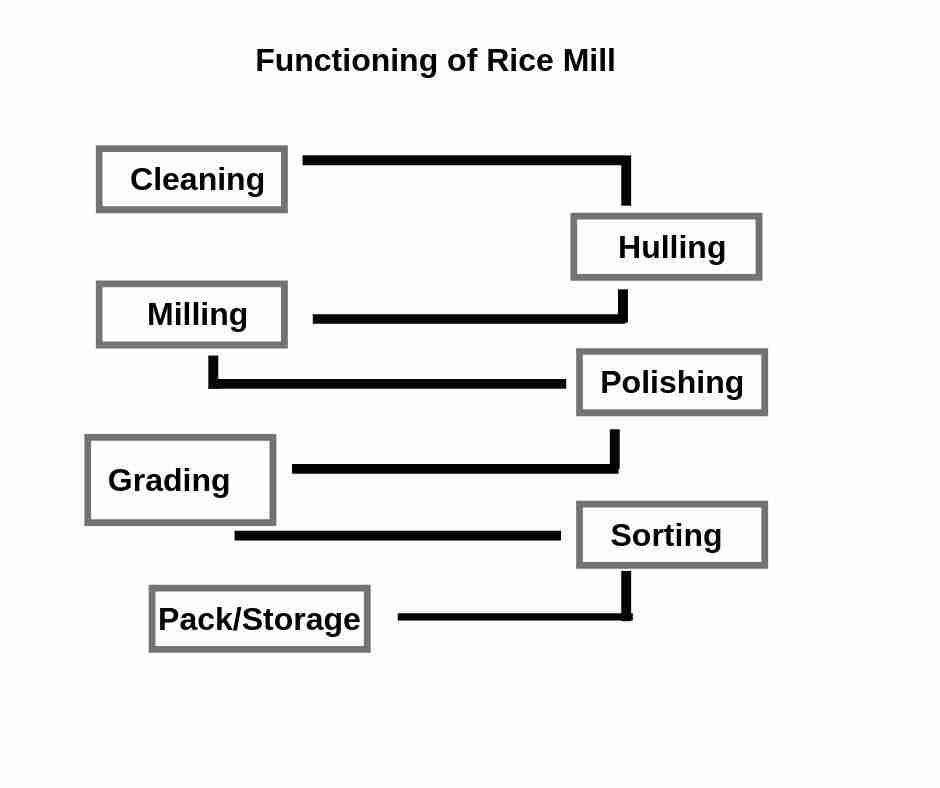

Rice milling is a meticulous journey that transforms paddy fields into polished grains, ready for culinary adventures. At the core of this process lies a series of stages that each serve a specific purpose, ensuring the rice is not only palatable but also nutritious. The journey begins with harvesting, where ripe grains are carefully gathered, and then moves to drying, essential for reducing moisture content and preventing spoilage. Once dried, the paddy undergoes threshing to separate the grains from the husk, followed closely by cleaning, which removes impurities like dirt and stones that could undermine the quality of the final product.

As the rice advances through the mill, several key processes come into play. The hulling process removes the outer husk, yielding brown rice, while milling further refines it to white rice by removing the bran layer. This process is followed by polishing, enhancing the grain’s luster, and a final sorting stage, which ensures uniformity by categorizing rice based on size and quality. The rice is then packaged and shipped, ready to grace tables around the world. The heart of grain processing, therefore, is not just about the machinery; it’s a symphony of steps that transform nature’s bounty into a staple food beloved by millions.

The Role of Technology in Modern Rice Mills

In the dynamic landscape of rice milling, technology acts as a transformative force, enhancing both efficiency and productivity. Modern rice mills are equipped with sophisticated machinery that automates the milling process, significantly reducing labor costs and human error. Advanced systems involve digital monitoring that keeps track of moisture content and grain quality, ensuring optimal output at every stage. Key components such as automatic rice graders, huskers, and de-stoners leverage precise engineering to minimize waste and maximize yield.

The integration of information technology also allows for better inventory management and logistics. Operators can now utilize software solutions that provide real-time data on production and supply chain metrics. This enables them to make informed decisions swiftly. Notably, the embrace of IoT (Internet of Things) in rice mills facilitates the collection of crucial data, which can be analyzed to enhance operational efficiency. Here’s a glimpse of some technological advancements:

| Technology | Description |

|---|---|

| Automated Milling Machines | Reduces manual handling and increases processing speed. |

| Quality Control Sensors | Ensures consistent grain quality through real-time monitoring. |

| Data Analytics Software | Optimizes production and inventory management through detailed insights. |

Furthermore, the advancements in energy efficiency play a significant role in reducing the carbon footprint of rice mills. Many operations are now shifting towards renewable energy sources such as solar or biomass, which help in lowering operational costs while promoting sustainability. By harnessing these technologies, rice mills not only contribute to higher food security levels but also aim towards a greener future.

Best Practices for Sustainable Rice Processing

Effective sustainable rice processing integrates various practices that enhance productivity while minimizing environmental impact. Mills can adopt energy-efficient technologies that significantly lower power consumption during milling operations. This includes using solar panels or biomass energy systems to power equipment, reducing reliance on fossil fuels. Furthermore, implementing efficient water management techniques can help conserve this precious resource, utilizing water recycling systems to purify and reuse water in the processing cycle. By choosing methods that reduce waste and energy use, rice mills contribute to a sustainable future.

Another aspect of sustainability in rice processing lies in the adoption of eco-friendly packaging solutions. Mills can shift towards biodegradable or recyclable materials, minimizing plastic waste associated with rice distribution. Incorporating partnerships with local farmers can also support sustainable sourcing practices, ensuring that rice is grown with minimal chemical inputs. Additionally, worker training programs focused on best practices can promote safety and efficiency, creating a culture of sustainability within the rice milling community.

Exploring the Economic Impact of Rice Mills on Local Communities

The presence of rice mills within a community extends far beyond the mere processing of grains; it catalyzes an economic ecosystem that transforms rural landscapes. These mills create jobs, offering a range of employment opportunities, from skilled positions in machine operation and maintenance to unskilled labor for transporting and packaging rice. This influx of jobs can lead to substantial income generation for families, supporting local economies and reducing poverty levels. Furthermore, rice mills often serve as a hub for various small-scale enterprises, including transportation services and retail outlets that sell rice and related products, ultimately fostering entrepreneurship.

Moreover, the economic benefits of rice mills stretch to agricultural stakeholders and local farmers. By purchasing paddy directly from farmers, rice mills ensure fair prices, which can enhance the livelihoods of those engaged in rice cultivation. This symbiotic relationship establishes a reliable market for farmers and encourages investment in better farming techniques. The following key points illustrate the broader impact on local communities:

- Increased Employment: Job opportunities within mills help sustain families.

- Support for Local Businesses: Mills promote entrepreneurship through ancillary services.

- Stable Market for Farmers: Mills provide a consistent demand for locally grown rice.

- Rural Development: Enhanced infrastructure and access to resources as mills thrive.

To encapsulate the financial significance, consider the following table reflecting potential economic contributions:

| Contribution Factor | Estimated Impact |

|---|---|

| Jobs Created | 50-100 direct jobs per mill |

| Annual Revenue for Farmers | $10,000 – $30,000 |

| Local Business Growth | 10-20 new businesses within 3 years |

| Investment in Infrastructure | 20% increase in local infrastructure spending |

Future Outlook

As we conclude our exploration inside the world of rice mills, we find ourselves at the intersection of tradition and innovation, where the age-old craft of grain processing meets modern technology. These bustling centers not only breathe life into the staple food that nourishes billions, but also embody the unsung heroics of skilled workers who transform rough grains into our daily sustenance. With every husked grain and every polished white rice, we witness a complex dance of machinery, labor, and knowledge—an intricate web spun with threads of history and future potential.

In understanding the journey from paddy to plate, we gain a deeper appreciation for this fundamental food source and the diligent efforts behind it. As we move forward, it is essential to remember the pivotal role rice mills play not only in bolstering economies but in fostering food security and cultural connections across the globe. So the next time you savor a bowl of rice, take a moment to reflect on the journey it has taken—from the heart of the rice mill, where the magic truly begins.