In the intricate tapestry of global agriculture, one staple stands out as both a dietary cornerstone and a cultural emblem: rice. Feeding billions and serving as a symbol of sustenance and heritage, rice embodies the intersection of tradition and innovation in farming practices. At the heart of this vital grain’s journey from paddy to plate lies the rice milling unit — a marvel of engineering and efficiency. This article delves into the essential role of these units, exploring their function, technological advancements, and the delicate balance they strike between preserving quality and enhancing productivity. Join us as we unveil the processes that transform rough grains into the polished pearls of nutrition cherished around the world, revealing the intricate layers of an industry that nourishes today’s global populace.

Exploring the Essential Components of a Rice Milling Unit

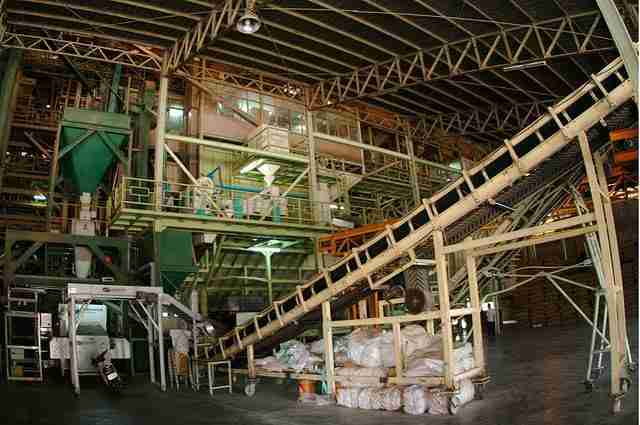

The rice milling unit is a sophisticated system designed to process paddy and transform it into high-quality rice. Each component plays a crucial role in ensuring efficiency and maximizing yield. The primary elements include the dehusking machine, polisher, grading machine, and destoner. These machines work in concert to separate the rice from the husk, polish it to perfection, and eliminate any impurities, resulting in clean, market-ready grains. The performance of a milling unit largely depends on the effectiveness of these components in handling various rice varieties and processing conditions.

In addition to the main machines, several supporting systems enhance the operation of a rice milling unit. These include:

- Elevators: Transport grains between different stages of the milling process.

- Fans: Cool the rice post-polishing and help in grain separation.

- Dust collectors: Maintain cleanliness and enhance safety by removing grain dust.

- Control panels: Monitor and regulate machine operations for optimal performance.

| Component | Function |

|---|---|

| Dehusking Machine | Removes husk from paddy grains |

| Polisher | Enhances the appearance of rice |

| Grading Machine | Sorts rice by size and quality |

Understanding the intricate functions of each component within the rice milling unit not only aids in optimizing performance but also in tailoring the milling process to meet specific market demands. This multifaceted approach ultimately contributes to producing rice that meets quality standards, catering to consumer preferences worldwide.

Mastering the Milling Process: Techniques for Enhanced Efficiency

In the intricate world of grain processing, the milling process stands as a pivotal element that affects both the quality and efficiency of the final product. Understanding the nuances of rice milling can significantly enhance the productivity of any milling unit. Advancing technique integration could greatly benefit operations. Incorporating state-of-the-art technology enables millers to achieve better yield rates and reduce processing time. Some key techniques include:

- Pre-cleaning: Removing impurities before milling ensures high-quality output.

- Proper Moisture Control: Maintaining optimal moisture levels helps prevent breakage during milling.

- Innovative Machinery: Investing in advanced milling machines can drastically increase efficiency.

Equally important is the adoption of systematic maintenance routines, which play a crucial role in sustaining operational performance. A well-maintained rice milling unit yields consistent results over time, minimizing downtime. Focus areas for maintenance should include:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Machine Calibration | Monthly | Ensures precision in milling |

| Cleaning & Lubrication | Weekly | Reduces wear and tear |

| Component Inspection | Quarterly | Prevents unexpected failures |

By merging innovative techniques with dedicated maintenance practices, milling units can optimize their processes, ultimately leading to enhanced production efficiency and superior product quality.

Quality Control: Ensuring Superior Rice Production

In the intricate journey from paddy to polished grains, quality control stands as an unwavering guard, ensuring that every kernel meets the highest standards. This meticulous process involves several crucial steps, each harmoniously aligned to enhance the overall quality and safety of rice. The heart of this initiative is laboratory testing, where samples are meticulously analyzed for moisture content, broken kernels, and foreign material. Additionally, visual inspections and sensory evaluations are conducted regularly to ensure consistency in color, aroma, and taste. These quality checkpoints enable producers to catch any anomalies early, ultimately resulting in a superior final product that satisfies both consumer expectations and market demands.

Moreover, an integral component of quality management is the engagement of skilled technicians and mill operators, who play a vital role in monitoring and adjusting the milling process. These professionals perform a range of tasks, including machinery calibration and maintenance checks, ensuring that the rice milling unit operates seamlessly. Establishing a culture of continuous improvement is essential; thus, regular training sessions are held to keep the team updated on the latest practices and technological advancements. This commitment not only elevates the quality of the rice produced but also enhances the efficiency and sustainability of the operation.

| Key Quality Control Components | Description |

|---|---|

| Laboratory Testing | Analyzes moisture, kernels, and impurities to ensure quality. |

| Visual Inspections | Examines color, aroma, and texture for consistency. |

| Machinery Calibration | Adjusts milling equipment for optimal performance. |

| Team Training | Enhances skills for improved quality management. |

Navigating the Future of Rice Milling Technology and Best Practices

In the ever-evolving landscape of rice milling, technology plays a pivotal role in enhancing efficiency and sustainability. Advanced machinery, equipped with state-of-the-art sensors and automated controls, streamlines the milling process, ensuring consistent quality and reduced waste. As the industry pivots towards a more eco-conscious approach, incorporating energy-efficient systems and renewable energy sources in rice milling units becomes essential. Employing innovative techniques such as water-saving practices and waste recycling methods not only minimizes environmental impact but also optimizes operational costs, enabling millers to remain competitive in a challenging market.

Best practices in rice milling extend beyond technology, emphasizing the importance of skilled labor and continual training. Engaging in regular workshops and training sessions ensures that operators are familiar with the latest advancements and safety protocols. Additionally, implementing a robust maintenance schedule for milling equipment can significantly extend machinery life while minimizing downtimes. Below are some crucial aspects to consider in enhancing the efficacy of rice milling operations:

- Quality Control Measures: Establish strict protocols for monitoring grain quality at each stage.

- Process Optimization: Regularly analyze workflow efficiency and seek areas for improvement.

- Data Utilization: Leverage data analytics for decision-making and trend forecasting.

- Community Engagement: Foster relationships with local rice farmers to create a sustainable supply chain.

Closing Remarks

As we conclude our exploration of the rice milling unit, we find ourselves at the intersection of tradition and technology, where the humble grain transforms into the staple that nourishes billions. This intricate dance of machinery and technique embodies more than mere processing; it captures the essence of agricultural innovation, sustainability, and economic vitality. The rice milling unit serves as a testament to our ability to honor the past while forging paths toward a more efficient and resource-conscious future.

Behind every grain of rice lies a story of cultivation, harvest, and meticulous processing, all carefully orchestrated within the heart of these units. As we unveil the layers of complexity and craftsmanship involved, we recognize the critical role these systems play in feeding a growing population and supporting livelihoods across the globe.

In understanding the rice milling unit, we gain insight not only into a vital industry but also into the cultural significance of rice itself—a food that connects us all. So, as we reflect on this intricate process, let us appreciate the unseen efforts that transform raw crops into the beloved staple that graces our tables, reminding us of the profound journey from field to fork.