Unlocking Potential: The Essential Guide to Rice Milling Units

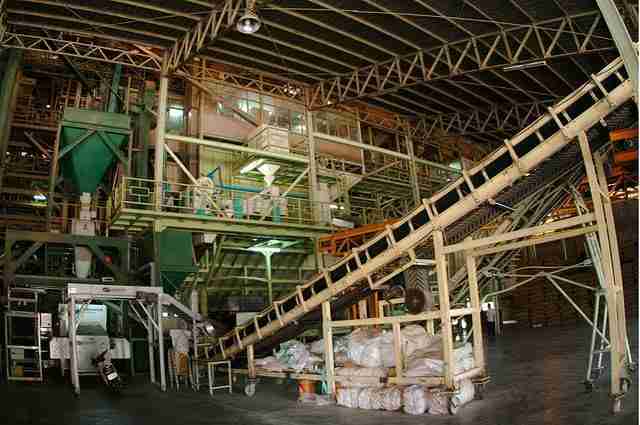

In a world that increasingly values efficiency and sustainability, the backbone of staple food production often goes unnoticed. Rice, a dietary cornerstone for billions, relies on an intricate process that begins long before it reaches our tables. At the heart of this transformation lies the rice milling unit—a dynamic environment where raw grains undergo a remarkable metamorphosis. This essential guide is designed to illuminate the multifaceted world of rice milling units, offering insights into their operation, technology, and significance within the agricultural landscape. Whether you are a seasoned industry professional, a budding entrepreneur, or simply curious about the journey of rice from field to fork, this comprehensive exploration will equip you with the knowledge to unlock the full potential of rice milling units. Join us as we delve into the machinery, processes, and innovations that define this vital sector, paving the way for enhanced productivity and sustainable practices in rice processing.

Understanding the Basics of Rice Milling Technology

Rice milling technology is the backbone of the rice supply chain, transforming raw paddy into the polished grains that are familiar to consumers worldwide. The process involves several stages, each specialized to enhance efficiency and maintain the quality of the rice. Key elements of the milling process include:

- Cleaning: Removing impurities such as stones, dirt, and husks.

- Hulling: Removing the outer husk to reveal brown rice.

- Milling: Polishing the brown rice to produce white rice. This includes grinding and polishing stages.

- Grading: Sorting rice based on size and quality to meet market standards.

Understanding these stages not only aids mill operators in optimizing their practices but also helps farmers market their products more effectively. As rice milling units become increasingly advanced, the integration of technology plays a crucial role in improving productivity. Modern milling equipment often features:

- Automated Systems: Reducing labor costs and errors.

- Sensors and Control Panels: Allowing for real-time monitoring of the milling process.

- Energy-Efficient Machines: Minimizing operational costs while maximizing output.

| Stage | Description |

|---|---|

| Cleaning | Elimination of contaminants. |

| Hulling | Removal of husks. |

| Milling | Polishing to produce white rice. |

| Grading | Sorting based on quality. |

Key Components and Their Roles in Enhancing Efficiency

To truly optimize the operations of a rice milling unit, understanding its integral components is essential. Each part not only plays a specific role but also contributes to the overall efficiency of the milling process. The main components include the following:

- Dehusking Machine: Responsible for removing the outer husk, ensuring that the rice kernels are ready for further processing.

- Sheller: Enhances the dehusking process by effectively separating the husks from the rice without damaging the grains.

- Milling Machine: Polishes the rice, enhancing its appearance and market value by removing the bran layer.

- Grading System: Sorts the milled rice according to size and quality, facilitating appropriate packaging and sales strategies.

Incorporating advanced technology into these components significantly boosts productivity. For instance, modern milling units may incorporate features like:

| Component | Feature | Benefit |

|---|---|---|

| Dehusking Machine | Automated Feed System | Increases throughput and reduces manual labor. |

| Shelter | Precision Calibration | Minimizes grain breakage and maximizes yield. |

| Milling Machine | Variable Speed Control | Allows adjustment for different rice types, improving efficiency. |

By understanding each component’s role and investing in modern technology, rice milling units can enhance output and significantly reduce waste. This strategic approach not only meets market demand but also ensures sustainability and profitability in the long run.

Best Practices for Sustainable and Profitable Operations

To achieve longevity and profitability in rice milling operations, adopting eco-friendly methods is essential. By integrating energy-efficient machinery and optimizing the production process, millers can significantly reduce their environmental footprint while also cutting costs. Consider implementing the following strategies:

- Utilize solar energy for operations to decrease reliance on fossil fuels.

- Conduct regular maintenance checks to ensure equipment efficiency and mitigate waste.

- Invest in water recycling systems to minimize water usage during milling.

- Source raw materials from sustainable farms committed to eco-friendly practices.

Beyond just sustainability, leveraging technology can bolster profitability. By employing automation in milling processes, businesses can enhance productivity and minimize labor costs. Additionally, adopting data analytics can provide insights into market trends and inventory management. Some effective technological solutions include:

| Technology | Benefit |

|---|---|

| Automated Milling Equipment | Boosts productivity and reduces wastage |

| Inventory Management Software | Optimizes stock levels and reduces holding costs |

| Quality Control Systems | Ensures high product standards and customer satisfaction |

Future Trends: Innovations Shaping the Rice Milling Industry

As the rice milling industry evolves, several innovations are beginning to shape its future landscape. The increasing incorporation of Internet of Things (IoT) technology is one of the most significant advancements, enabling rice mills to monitor and optimize operations in real time. This connectivity empowers mill operators to make data-driven decisions, enhancing efficiency and productivity. Additionally, the adoption of machine learning and AI algorithms optimizes milling processes by predicting equipment failures and minimizing downtime, leading to reduced operational costs. Other noteworthy trends include advancements in energy-efficient machinery, which are crucial in reducing the environmental impact of rice milling, thereby adhering to global sustainability goals.

Moreover, the rise of automated systems is paving the way for more streamlined operations. Features such as robotic automation in sorting and packaging are enhancing speed and precision, which ensures consistent quality while reducing manual labor dependence. The emergence of biotechnology is also promising, as innovative methods for pest control and crop improvement, such as genetically modified seeds designed for better yield, are gaining traction. To illustrate these trends, the following table highlights some key innovations and their corresponding benefits:

| Innovation | Benefits |

|---|---|

| IoT Integration | Real-time monitoring and data-driven decision-making |

| Energy-efficient Machinery | Reduced operational costs and environmental footprint |

| Automated Systems | Enhanced speed, precision, and reduced labor costs |

| Biotechnology | Improved crop yield and pest resistance |

Closing Remarks

As we draw the curtains on our exploration of rice milling units, it becomes clear that these seemingly simple machines are the unsung heroes of the agricultural landscape. With the power to transform raw grains into polished rice, they not only boost productivity but also foster economic growth and sustainability in communities around the globe. Unlocking the potential of rice milling technology is not just about enhancing efficiency; it’s about embracing a future where food security, innovation, and local entrepreneurship thrive hand in hand.

Whether you’re a seasoned farmer, an aspiring entrepreneur, or simply a curious reader, this guide serves as a stepping stone into the intricate world of rice milling. The insights shared here illuminate not just the technical aspects, but also the broader implications of this vital industry. As we move forward, let us remain committed to harnessing the potential of rice milling units while nurturing the agricultural ecosystems they support.

In our united effort to cultivate a more sustainable food system, may we remember that every grain milled is a step toward progress, a story of transformation, and a promise of prosperity. With new knowledge at your fingertips, the possibilities are endless—let’s continue to cultivate growth, one grain at a time.