In the heart of rural landscapes and bustling urban centers, a silent transformation occurs that captivates the essence of agriculture: rice milling. This intricate process, often overlooked, plays a pivotal role in converting golden grains into the staple food that nourishes millions across the globe. While rice paddies sway gracefully under the sun, the true magic lies in the hidden chambers of rice milling units, where technology and tradition intertwine to elevate raw harvests into polished perfection. In this article, we delve into the inner workings of these essential facilities, exploring the sophisticated machinery, meticulous processes, and the human expertise that together transform unassuming grains into the beloved rice that fills plates around the world. Join us on a journey through the intricate layers of rice milling, where every grain carries the story of its journey from field to fork.

Understanding the Basics of Rice Milling Processes

Rice milling is a multifaceted process that transforms paddy into market-ready rice, ensuring the preservation of grain quality while enhancing its edibility. The initial stage involves dehusking, where the outer husk is removed using machines known as huskers, which employ an abrasive method to separate the husk from the rice grain. Following dehusking, the rice undergoes milling, where the grain’s bran layer is polished away, enhancing both the appearance and taste. This stage is crucial as it also minimizes the risk of spoilage and prepares the rice for long-term storage. The milled rice can then be categorized into various grades depending on the level of polishing and the presence of impurities.

Throughout the milling process, several key steps are essential for producing high-quality rice. Key operations include:

- Pre-cleaning: Removing impurities like stones and dirt before milling.

- De-stoning: Further refining to ensure no stone contaminates the final product.

- Polishing: Enhancing the surface of the rice grains for improved aesthetic qualities.

- Color sorting: Using optical sensors to eliminate discolored or defective grains.

To better understand the milling stages, the following table highlights the typical time frames and key functions associated with each step:

| Processing Stage | Duration (Approx.) | Primary Purpose |

|---|---|---|

| Pre-cleaning | 15-30 minutes | Remove impurities |

| Dehusking | 20-40 minutes | Separate husk from rice |

| Milling | 30-60 minutes | Polish and refine grains |

| Color Sorting | 10-20 minutes | Ensure uniform quality |

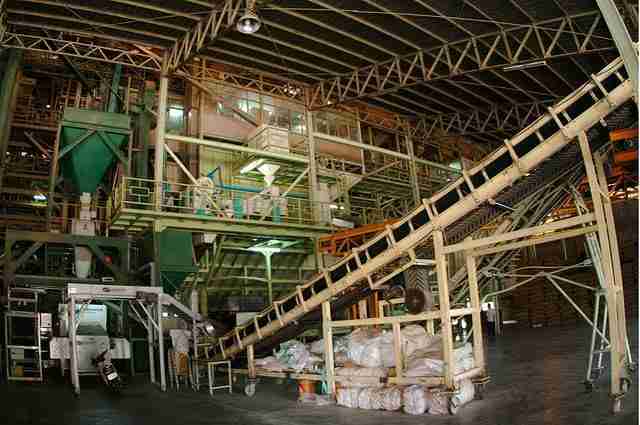

Essential Components of Modern Rice Milling Units

Modern rice milling units are meticulously engineered systems that transform raw paddy into finely polished rice grains ready for distribution. The process begins with the pre-cleaning stage, where impurities such as dirt, stones, and husks are removed to ensure a quality yield. This is followed by parboiling, a technique that partially cooks the rice before milling, enhancing its nutritional value and shelf life. The centerpiece of the milling process is the husker, which efficiently separates the rice grain from its outer husk, utilizing the power of rubber rolls for a gentle yet effective husking operation. Essential to achieving the desired grain quality is the milling machine, which can be a combination of various machines such as the crusher and polisher, ensuring uniformity and brightness in the final product.

In addition to the core machinery, the layout of modern rice milling units includes support systems that streamline production. A dust collection system plays an important role, minimizing air pollution and ensuring worker safety. Furthermore, automation is paramount, as programmable logic controllers (PLCs) allow for real-time monitoring and adjustment of milling parameters. quality control labs are integrated within the milling unit, where samples of the rice undergo rigorous testing for moisture content, head rice yield, and nutritional analysis, ensuring that only the best product reaches the market.

| Component | Function |

|---|---|

| Pre-Cleaner | Removes impurities from raw paddy |

| Husker | Separates rice grains from husk |

| Milling Machine | Processes rice for uniformity and polish |

| Dust Collection System | Minimizes pollution and maintains air quality |

| Quality Control Lab | Tests rice for quality standards |

Optimizing Efficiency Through Technological Innovations

In the realm of rice milling, the implementation of cutting-edge technology has dramatically transformed traditional processes, leading to enhanced productivity and reduced operational costs. Modern rice milling units now incorporate automated systems that streamline workflow, resulting in faster turnaround times and fewer human errors. With smart sensors monitoring moisture and temperature during milling, the quality of the end product is maintained at optimal levels. Additionally, advances in AI-driven analytics provide mill operators with real-time insights, allowing for quick adjustments and improved decision-making.

Furthermore, innovations such as automated cleaning procedures and energy-efficient machinery are crucial in minimizing waste and maximizing resource use. By adopting environmentally-friendly practices, these mills not only contribute to sustainability but also benefit from lower energy costs. The integration of IoT devices enables seamless communication between different components of the milling unit, ensuring consistent quality. The following table illustrates key technological advancements in rice milling:

| Technology | Benefit |

|---|---|

| Automated Systems | Increases efficiency and accuracy |

| Smart Sensors | Monitors quality in real-time |

| AI Analytics | Improves decision-making |

| Energy-Efficient Machinery | Reduces operational costs |

Best Practices for Quality Control in Rice Milling Operations

To ensure the highest quality of rice during milling operations, implementing systematic quality control measures is essential. These practices not only enhance the end product but also contribute to a more efficient milling process. Regular inspection of equipment is vital; operators should establish a schedule for checks that includes cleaning, calibration, and maintenance of machines. Employing visual color sorting can effectively identify discolored or defective grains early in the processing, allowing for immediate corrective action. By prioritizing sample testing of milled rice for moisture content and presence of impurities, facilities can maintain high standards and minimize spoilage.

Another crucial aspect of quality assurance involves educating the workforce on best practices and operational standards. Training sessions focusing on proper handling techniques and the implications of contamination can significantly reduce quality issues. Creating a culture of accountability encourages employees to report problems promptly and take ownership of maintaining quality. Furthermore, keeping a detailed log of all quality control measures, including results from tests and inspections, allows for transparent tracking and continuous improvement. When every member of the team is engaged in quality control, the benefits are evident in the consistency and excellence of the final product.

Key Takeaways

As we conclude our exploration of rice milling units, it becomes evident that the journey from paddy to polished grain is a remarkable interplay of technology, tradition, and transformation. Each step in the milling process not only enhances the quality and shelf life of rice but also preserves the vital nutrients that nourish millions around the globe. The intricate machinery at work, from huskers to polishers, reflects both innovation and the agricultural heritage of rice cultivation.

Understanding these inner workings opens a window into the complexities of food production and the innovations that continue to shape the industry. As we seek sustainable solutions for the challenges ahead, the evolution of rice milling remains a testament to human ingenuity and resilience. Whether enjoyed in a simple bowl or as part of a culinary masterpiece, the grains we savor carry stories that connect us to farmers, millers, and countless cultures.

In a world where the demand for high-quality food continues to rise, the transformation of grains through rice milling units stands as a vital link in the food supply chain. As we appreciate the humble grain on our plates, let us acknowledge the intricate systems that bring it to us and the ongoing advancements aimed at making these processes more efficient and sustainable for future generations. As we move forward, embracing both tradition and technology will ensure that the journey of rice remains as rich and profound as the grains themselves.