Transforming Grains: The Essentials of Rice Milling Units

In the heart of agriculture, where the golden fields sway gently under the sun, lies a crucial process that transforms humble grains into a staple of nourishment for millions: rice milling. This vital stage not only enhances the quality and taste of rice but also determines its nutritional value and market readiness. As we delve into the world of rice milling units, we will uncover the essential components and technologies that make this transformation possible. From the intricate machinery that shells and polishes the grains to the skilled hands that oversee the operation, every aspect of rice milling plays a significant role in delivering the final product to consumers. Join us as we explore the fundamentals of rice milling units, their significance in the agricultural landscape, and the innovations that are shaping the future of this time-honored process.

Understanding the Rice Milling Process: A Journey from Paddy to Polished Grain

The rice milling process is a fascinating journey that begins with paddy, the harvested grain still enveloped in its protective husk. To transform paddy into the familiar white grains found on dinner tables worldwide, several crucial steps are employed. Initially, the paddy is thoroughly cleaned to remove impurities and foreign materials that may have accompanied it during harvesting. This step is crucial for ensuring the quality of the final product. Following this, the grains undergo hulling, where the husk is removed, resulting in brown rice. At this stage, the grain retains its bran layer, which is rich in nutrients but lacks the appealing gloss that many consumers prefer.

Next in the milling process is the white rice transformation, where the bran and germ are stripped away through a process known as polishing. This step not only improves the aesthetics of the rice but also extends its shelf life. Various milling units utilize a combination of machines to achieve these results effectively:

- Dehusking machine: Efficiently removes the outer husk.

- Whitener: Polishes brown rice, eliminating the bran layer.

- Grader: Sorts rice by size and quality.

To better understand the rice milling process, a simplified overview of the steps is outlined below:

| Step | Description |

|---|---|

| 1. Cleaning | Removes impurities from paddy. |

| 2. Hulling | Removes the husk to produce brown rice. |

| 3. Whitening | Strips bran and germ, resulting in polished white rice. |

| 4. Grading | Sorts rice based on size and quality. |

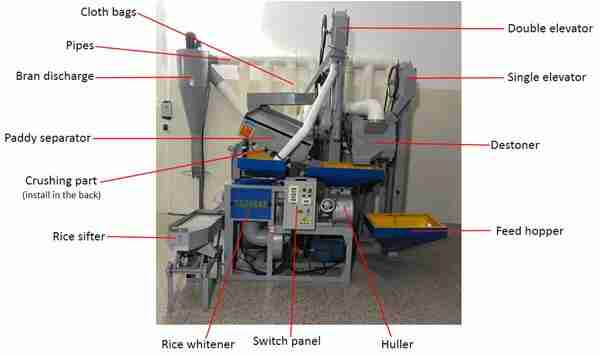

Key Components of an Efficient Rice Milling Unit: A Focus on Technology and Design

In the world of rice milling, the integration of cutting-edge technology and practical design principles can drastically enhance productivity and quality. Automated systems play a crucial role in ensuring the efficient operation of a milling unit by minimizing human intervention and reducing the chances of error. Key features that should be incorporated into the design include:

- High-precision milling machines: For optimal grain processing and minimal breakage.

- Advanced sorting mechanisms: Utilizing optical sensors to ensure only the highest quality grains proceed to packaging.

- Real-time monitoring sensors: To track moisture levels and prevent spoilage during milling.

Moreover, the layout of the milling unit must support the flow of materials while promoting efficiency. A well-structured workflow can significantly reduce processing time and waste. Important design considerations include:

- Streamlined conveyor systems: Designed to move grains seamlessly from one stage to another.

- Ergonomic workspaces: That allow operators to easily manage machinery with minimal strain.

- Efficient storage solutions: Such as silos that ensure optimal conditions for storing both raw and processed rice.

| Component | Benefit |

|---|---|

| Automated Sorters | Enhance quality control |

| Moisture Sensors | Prevent grain spoilage |

| Ergonomic Equipment | Increase operator safety |

Best Practices for Quality Control in Rice Milling: Ensuring Consistent Production Standards

Quality control is crucial in rice milling to maintain a high standard and ensure that the final product meets consumer expectations. Establishing effective quality checkpoints throughout the milling process is essential. These checkpoints can include:

- Initial Grain Assessment: Evaluate the quality of incoming paddy, checking for moisture content, impurities, and damaged grains.

- Milling Process Monitoring: Regularly inspect machinery settings and cleanliness to ensure optimal processing efficiency.

- Final Product Sampling: Test the milled rice for appearance, smell, and taste to confirm it meets established grading standards.

Incorporating standard operating procedures (SOPs) helps minimize variability and ensures consistent product quality. Furthermore, training staff on these SOPs is vital, as well-informed employees can recognize discrepancies more readily. The importance of data tracking should not be overlooked either. Implementing a digital quality management system can facilitate real-time monitoring and analysis, leading to swift corrective actions. Below is an example of a simple quality tracking table that can be integrated into the rice milling workflow:

| Quality Parameter | Standard Value | Actual Value | Status |

|---|---|---|---|

| Moisture Content (%) | 14-16 | 15 | Within Range |

| Broken Grain (%) | Less than 5 | 3 | Within Range |

| Foreign Material (%) | Less than 2 | 1 | Within Range |

Sustainability in Rice Milling: Innovations for a Greener Future in Grain Processing

The rice milling industry is undergoing a significant transformation, driven by the imperative for sustainability. Innovative technologies are emerging that not only enhance productivity but also minimize environmental impact. Key advancements include:

- Energy-efficient machinery: Modern milling equipment consumes less energy and incorporates renewable energy sources.

- Water recycling systems: Closed-loop systems effectively reuse water, reducing waste and conserving essential resources.

- Biomass utilization: By-products from rice milling, such as husks and bran, are increasingly being converted into bioenergy, leading to reduced overall waste.

Furthermore, the integration of smart technology is revolutionizing grain processing within rice mills. Sensors and data analytics play a crucial role in optimizing production processes, enabling precise control over milling and reducing losses. The adoption of sustainable practices is amplified by the commitment to certified organic and fair trade rice production, aligning with consumer demands for eco-friendly products. Consider the following table that summarizes some of these cutting-edge innovations:

| Innovation | Description | Benefit |

|---|---|---|

| Energy-efficient Machines | Modern equipment designed to use less power | Lower operational costs |

| Water Recycling | Systems that reuse water in the milling process | Conserves water resources |

| Biomass Energy | Utilizing milling by-products for energy | Reduces waste and emissions |

In Retrospect

In the intricate dance of agriculture and technology, rice milling units stand at the forefront, bridging the gap between raw harvest and culinary delight. Through the meticulous processes of cleaning, hulling, and polishing, these essential machines not only elevate the quality of our daily staples but also empower farmers and communities to unlock the full potential of their crops. As we’ve explored the nuances of this transformative journey—from harvesting golden grains to the final product on our plates—it’s clear that the role of rice milling units transcends mere functionality. They are a testament to innovation, sustainability, and the age-old relationship between mankind and the land.

As we conclude our exploration, let us appreciate the artistry behind grain transformation, where technology meets tradition and every kernel tells a story. Whether you’re a farmer, a miller, or simply a lover of rice, understanding the essentials of these units allows us to celebrate the journey of our food and the global tapestry that connects us all. Embrace this knowledge, for in every grain lies not just sustenance, but a legacy of human ingenuity and resilience. Here’s to the future of rice milling, and to the grains that nourish our bodies and cultures alike.