In the heart of countless culinary traditions lies a humble yet transformative ingredient: rice. From the basmati grains that grace festive feasts to the sticky varieties that accompany Asian delicacies, rice serves as a staple for billions around the globe. Yet, before it adorns our plates, this versatile grain embarks on an incredible journey that is often overlooked. Enter the world of rice milling units, where the art and science of grain transformation come together in perfect harmony. This article delves into the intricate processes, innovative technologies, and the skilled craftsmanship that breathe life into paddy—turning it into the polished grains we cherish. As we unveil the sometimes invisible journey of rice from field to fork, we invite you to explore the artistry that makes this simple grain a key player in kitchens worldwide.

Understanding the Rice Milling Process: From Grain to Gourmet

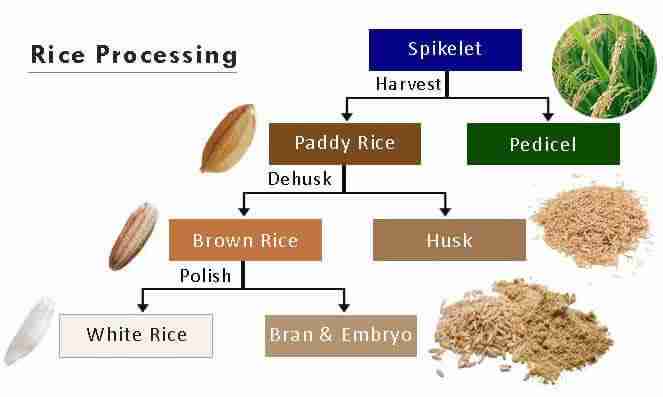

The journey from harvested grains to the polished, tantalizing rice on your plate begins with a meticulous milling process that involves various stages, each vital to ensuring the quality and flavor of the final product. Initially, the paddy is cleaned to remove impurities such as stones, dust, and other foreign materials. This is followed by hulling, where the rough husk is separated from the rice grain to yield brown rice. At this stage, the rice retains its bran layer, which adds nutritional value. To reach the highly sought-after white rice, milling is carried out, where the bran layer is removed, resulting in a polished grain with a delightful sheen.

Advanced rice milling units employ state-of-the-art technology to enhance efficiency and quality control. These units typically consist of several key components:

- Pre-cleaner: Ensures the rice is free from foreign materials.

- Husker: Removes the outer husk from the paddy.

- Separator: Sorts the brown rice from the husk and broken grains.

- Whitener: Polishes the brown rice to produce white rice.

- Grader: Categorizes rice according to size and quality.

| Stage | Function |

|---|---|

| Cleaning | Eliminate foreign materials |

| Hulling | Separate husk from grain |

| Milling | Remove bran for white rice |

| Grading | Ensure uniform size and quality |

Employing such detailed processes not only enhances the quality of the rice but also maximizes its shelf life and overall marketability. As consumers continue to seek superior flavors and textures, the rice milling industry adapts by integrating innovative techniques, focusing on sustainability, and producing grains that cater to distinct culinary preferences. Each step in the milling process contributes to transforming a simple grain into an ingredient worthy of gourmet cuisine.

Essential Components of a Successful Rice Milling Unit

At the heart of an effective rice milling unit lies a well-designed production floor, where every component plays a crucial role in ensuring efficiency and quality. Machinery is the backbone of this operation, featuring advanced rice hullers, polishers, and separators that transform paddy into high-quality rice. These machines must be calibrated precisely to minimize breakage and maximize yield. In addition to state-of-the-art machinery, proper layout and workflow are essential. An optimized layout reduces bottlenecks and enhances the movement of materials, allowing for a seamless transition from one process to the next.

Equally important is the attention to quality control at every stage of milling. Routine checks and maintenance on machinery ensure longevity and reliability, while sampling and testing of the rice produced help maintain high standards. The workforce must be well-trained, understanding both the technical and operational aspects of the equipment. Furthermore, logistics and storage solutions must be carefully managed to keep the supply chain running smoothly. Efficient storage methods protect the milled rice from spoilage and contamination, ensuring that customers receive the best quality product. Together, these components create a cohesive environment that supports the art of rice milling.

Maximizing Efficiency: Technology Innovations in Rice Processing

The evolution of rice processing has been significantly influenced by recent technological advancements, which have streamlined operations and enhanced product quality. Key innovations include the integration of automated milling systems, which reduce human error and increase processing speed. This technology employs sensors and data analytics to continuously monitor grain conditions, ensuring optimal milling parameters are maintained. Other noteworthy developments encompass the use of energy-efficient machinery, which not only lowers operational costs but also minimizes the environmental impact typically associated with traditional rice milling techniques.

Additionally, smart processing units equipped with IoT capabilities provide real-time data to stakeholders, facilitating informed decision-making throughout the supply chain. This interconnectedness allows for improved inventory management and quality control, resulting in higher customer satisfaction. The implementation of these modern advancements has led to transformational changes in rice processing, helping producers embrace sustainability and efficiency. Below is a simple overview of the benefits realized through innovative technologies:

| Innovation | Benefits |

|---|---|

| Automated Milling Systems | Increased speed and precision in processing. |

| Energy-Efficient Machinery | Lower operational costs and reduced carbon footprint. |

| Smart Processing Units | Enhanced data analytics for quality control. |

Sustainable Practices in Rice Milling for a Greener Future

In an era where sustainability is paramount, the rice milling industry has taken significant strides toward minimizing its environmental footprint. By incorporating innovative techniques and eco-friendly practices, milling units are reshaping their operations to benefit both the planet and consumers. Key initiatives include:

- Water Conservation: Implementing closed-loop systems reduces water wastage, ensuring that every drop is utilized efficiently.

- Energy Efficiency: The adoption of renewable energy sources, such as solar and wind power, contributes to a drastic reduction in reliance on fossil fuels.

- Waste Management: By-products from milling, such as husks and bran, are repurposed as biomass for energy generation or as nutritious animal feed.

Moreover, modern milling units often integrate smart technology and automation to optimize production processes and minimize waste. This technological evolution not only boosts productivity but also promotes sustainable management of resources. Economic benefits arise through:

| Benefit | Description |

|---|---|

| Cost Reduction | Lower energy and water bills lead to significant operational savings. |

| Brand Loyalty | Consumers increasingly prefer eco-friendly products, enhancing market competitiveness. |

| Regulatory Compliance | Proactive sustainable practices ensure adherence to environmental regulations. |

To Conclude

As we conclude our exploration of the intricate world of rice milling units, it becomes clear that transforming grains is a delicate dance between tradition and technology. From the rhythmic thud of wooden mortars in ancient villages to the precision of modern machines, each method reflects a history rich with cultural significance and innovation. This art of milling not only nourishes communities but also sustains economies, weaving together the fabric of societies reliant on this staple.

The journey of rice from paddy to plate is more than a mere process; it is a testament to human ingenuity and resilience. As rice milling units continue to evolve, they embody a fusion of artisanal craftsmanship and cutting-edge advancements. In recognizing their pivotal role, we can appreciate not just the grains that fill our bowls, but the stories, struggles, and triumphs they represent.

Ultimately, understanding the nuances of rice milling is an invitation to celebrate the simple yet profound impact of this grain on our lives. So, next time you savor a dish of fragrant rice, take a moment to reflect on the journey it undertook—from the fields to the milling units, and finally to your table—transforming not just grains, but also the communities and cultures that cherish them.