Rice, a staple food for billions around the world, has been cultivated for thousands of years. In today’s modern world, rice mills play a crucial role in processing and packaging this beloved grain. If you’re looking to invest in a 4 ton rice mill plant, look no further. This ultimate guide is your one-stop resource for everything you need to know about setting up and operating a successful rice mill plant. From selecting the right machinery to understanding the milling process, we’ve got you covered every step of the way. Let’s dive in and unlock the secrets to running a thriving rice mill operation.

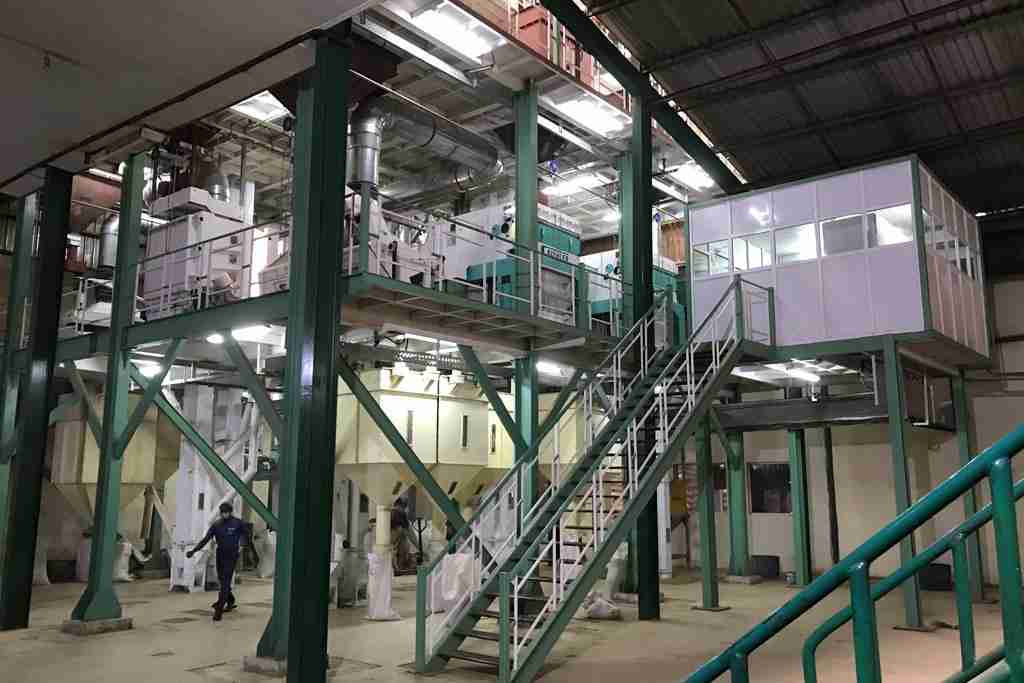

Key Components of a 4 Ton rice mill plant

When setting up a 4 ton rice mill plant, there are several key components that are essential for efficient operation. One of the most important components is the paddy separator, which helps to separate the hulls and rice grains. This process is crucial for producing high-quality rice that is free from impurities.

Another essential component of a 4 ton rice mill plant is the rice polisher, which is used to give the rice a shiny appearance and improve its texture. Additionally, the rice grader is vital for sorting the rice grains based on size, ensuring uniformity in the final product. Other important components include the destoner, husker, and whitener, all of which play a crucial role in the rice milling process.

Maximizing Efficiency in Rice Milling Operations

When it comes to , having a 4 ton rice mill plant can greatly improve productivity and output. This comprehensive guide covers everything you need to know about setting up and running a successful plant, from selecting the right equipment to optimizing your processes for maximum efficiency.

Key components of a 4 ton rice mill plant include:

- Rice Husker: Removes the husk from the paddy to produce brown rice.

- Rice Polisher: Polishes the brown rice to remove the bran layer and improve appearance.

- Grain Separator: Separates the rice into different sizes for packaging.

- Bagging Machine: Automates the packaging process for faster production.

Choosing the Right Machinery for Your rice mill plant

In order to ensure that your rice mill plant operates efficiently, it is crucial to choose the right machinery that meets the specific needs of your production process. With a 4 ton rice mill plant, there are several key pieces of equipment that you will need to consider investing in. One essential machine is the paddy separator, which helps to separate the husk from the brown rice. Additionally, a rice whitener is necessary to remove the bran layer and polish the rice grains, giving them a shiny finish. Another important piece of machinery for a 4 ton rice mill plant is a rice grader, which helps to sort the rice grains based on size.

Furthermore, a rice packaging machine is essential for efficiently packing the processed rice into bags for distribution. Additionally, investing in a rice bran oil extraction machine can help to maximize the value of your rice milling process by extracting oil from the rice bran. Lastly, a rice huller machine is crucial for removing the outer husk of the rice grains to make them more accessible for further processing. By carefully selecting the right machinery for your 4 ton rice mill plant, you can ensure that your production process runs smoothly and efficiently.

Maintenance Tips for Longevity and Performance

When it comes to maintaining a 4 ton rice mill plant, there are several key tips to consider in order to ensure longevity and optimal performance. Regular maintenance is crucial for keeping your equipment running smoothly and efficiently. One important tip is to regularly check and clean the machinery to remove any debris or build-up that can cause clogs or damage. Additionally, lubricating moving parts such as the conveyor belts and rollers can help prevent wear and tear, extending the lifespan of your equipment.

Another essential maintenance tip is to regularly inspect and replace any worn or damaged parts. This includes checking for loose screws or bolts, worn belts, and damaged bearings. By staying on top of these small repairs, you can prevent larger issues from arising that could lead to costly downtime. Ultimately, following these maintenance tips will not only help extend the life of your 4 ton rice mill plant but also optimize its performance for increased productivity.

To Conclude

In conclusion, this ultimate guide has provided you with all the information you need to set up a successful 4 ton rice mill plant. From selecting the right location to choosing the best equipment, we have covered every aspect to help you achieve maximum productivity and efficiency. We hope this article has been helpful in guiding you through the process of setting up your own rice mill plant. Good luck on your journey towards a successful and thriving business!