Reviving Grains: Exploring the rice mill plant Revolution

In a world increasingly focused on sustainable practices and innovative agriculture, the humble grain takes center stage in a remarkable revival. As the backbone of countless diets and economies, rice has long been celebrated not just as a staple food, but as a source of cultural identity and agricultural heritage. Today, the rice mill plant is undergoing a transformation—one that blends traditional methods with cutting-edge technology, creating a seamless dance between the past and the future of grain production. This article delves into the revolution sweeping through rice mills around the globe, exploring how advancements in processing techniques, sustainability initiatives, and community engagement are breathing new life into the rice industry. Join us as we uncover the stories, challenges, and triumphs behind this pivotal movement, and discover how the revival of grains is shaping the future of food security and ecological balance.

Unveiling the Potential of Ancient Grains in Modern Agriculture

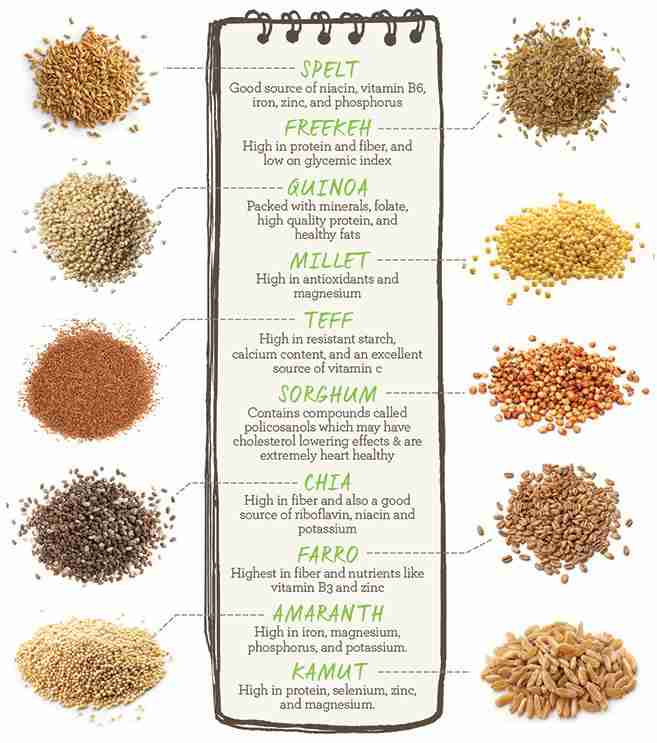

The rich tapestry of ancient grains, often overlooked in favor of their more modern counterparts, holds significant promise for contemporary agriculture. As farmers face the dual challenge of climate change and the demand for more sustainable practices, these grains present a viable solution. Transitioning to ancient grains such as spelt, quinoa, and farro not only contributes to biodiversity but also provides a resilient option that thrives in varying environmental conditions. Their unique growing characteristics enable farmers to cultivate crops that require less water and resist pests without heavy pesticide use, aligning seamlessly with eco-friendly initiatives.

Moreover, the revival of rice mill plants is instrumental in processing these ancient grains, facilitating their entry into the mainstream market. These modern facilities are equipped with cutting-edge technologies that enhance efficiency while maintaining the nutritional integrity of the grains. Innovative milling techniques allow for better extraction of nutrients and flavors, capturing the essence of each grain. Consider the benefits of integrating ancient grains into today’s diets:

- Enhanced Nutritional Profile: Rich in essential amino acids and fiber.

- Culinary Versatility: Can be used in a variety of dishes from salads to baked goods.

- Environmental Benefits: Require less resource input and support soil health.

Innovative Technologies Transforming Rice Milling Processes

As the global demand for efficient rice production continues to rise, innovative technologies are stepping in to reshape the landscape of rice milling. One of the revolutionary advancements is the adoption of automated milling systems, which significantly reduce human error and increase consistency in grain processing. These state-of-the-art machines utilize smart sensors and AI algorithms to monitor every stage of milling, ensuring optimal quality control. Additionally, advancements in precision engineering have led to the development of machines that maximize yield, minimizing grain loss during the milling process and enhancing overall productivity.

Furthermore, the integration of sustainable practices and energy-efficient technologies is becoming increasingly prominent in modern rice mills. Bioenergy systems and solar power installations are being incorporated to reduce carbon footprints and operational costs. Mills are also utilizing water recycling techniques to minimize waste and contribute to conservation efforts. Together, these innovations not only elevate operational efficiency but also promote a more environmentally responsible approach to rice milling, making the industry more resilient and future-ready.

| Technology | Benefit |

|---|---|

| Automated Milling Systems | Improved consistency and reduced human error |

| Precision Engineering | Maximized yield and minimized grain loss |

| Bioenergy Systems | Lower carbon footprint and operational costs |

| Water Recycling Techniques | Promotion of sustainability and conservation |

Sustainable Practices for Enhancing Rice Mill Efficiency

Embracing sustainability in rice milling is not only beneficial for the environment but also enhances operational efficiency. By integrating renewable energy sources such as solar and biogas, rice mills can significantly reduce their reliance on fossil fuels. This shift not only lowers operational costs but also promotes energy independence. Furthermore, the adoption of precision agriculture techniques allows for a more efficient use of resources, minimizing waste and optimizing crop yields. The potential benefits of these initiatives include:

- Lower carbon footprint: Reducing greenhouse gas emissions through cleaner energy sources.

- Cost savings: Decreasing energy costs with the use of renewable resources.

- Enhanced crop management: Utilizing technology to make informed decisions that lead to better outcomes.

To further enhance the efficiency of rice mills, implementing water conservation strategies is crucial. Techniques like rainwater harvesting and the installation of water-efficient machinery can drastically reduce water usage. By recycling water within the milling process, mills can minimize waste and lower operational costs. Additionally, collaborating with local farmers to adopt sustainable farming practices can create a symbiotic relationship that supports the rice supply chain. The rewards of these practices encompass:

| Practice | Benefit |

|---|---|

| Water-efficient Machinery | Reduces water consumption significantly |

| Rainwater Harvesting | Provides an alternative water source |

| Collaboration with Local Farmers | Strengthens supply chain sustainability |

Exploring Market Trends and Consumer Preferences in Grain Products

The resurgence of interest in grain products has been shaped by a myriad of market dynamics and shifting consumer preferences. Today’s consumers are increasingly health-conscious, leading to a significant uptick in the demand for whole grains and minimally processed foods. Factors influencing these trends include:

- Health Awareness: Consumers are seeking out grains that offer nutritional benefits, such as high fiber content, vitamins, and minerals.

- Functional Foods: There is a rising trend towards products that contribute to well-being, including ancient grains like quinoa and spelt.

- Sustainability: Environmentally friendly practices in grain production and processing are becoming essential to attract eco-conscious buyers.

As the industry evolves, rice mill plants are adapting to cater to these changing demands, reflecting a broader commitment to innovation. The integration of technology in milling operations not only increases efficiency but also preserves the nutritional quality of grains. Consider the following insights on modern rice mill plants:

| Features | Benefits |

|---|---|

| Advanced milling machinery | Enhances efficiency and precision |

| Integrated quality control systems | Ensures product consistency and safety |

| Sustainable sourcing practices | Appeals to environmentally-conscious consumers |

Future Outlook

As we draw the curtain on our exploration of the rice mill plant revolution, it is clear that this movement goes beyond mere machinery and processing techniques. It embodies a heartfelt revival of ancient grains, weaving together tradition and innovation to meet the evolving challenges of our food systems. The advancements in milling technology not only promise higher efficiency and sustainability but also honor the legacy of rice cultivation that has nourished populations for centuries.

In this journey through the world of rice mills, we have witnessed how communities are reimagining their agricultural landscapes, embracing practices that respect both the environment and the rich heritage of their grains. As we turn the page to the future, it is crucial for stakeholders — from farmers to consumers — to continue advocating for practices that reinforce this revolution.

So, let us carry forward the lessons learned and the connections made, pooling our efforts to support the resurgence of grains that not only fill our plates but also feed our cultures and economies. In this ever-evolving narrative, the story of rice milling is just beginning, and with each grain, we sow the seeds of a sustainable future.