In a world where culinary experiences are becoming increasingly sophisticated, the journey from farm to table is undergoing a remarkable transformation. At the heart of this evolution lies a humble yet versatile staple: rice. As global palates expand and consumer preferences shift towards quality and authenticity, rice milling units have emerged as key players in the quest for gourmet dining. These specialized facilities not only enhance the quality of rice—ensuring it meets the diverse needs of chefs and home cooks alike—but they also help to optimize the entire supply chain, from grain to gourmet. In this article, we will explore how modern rice milling units are revolutionizing the industry, streamlining processes, and elevating the status of rice from a basic pantry staple to a gourmet ingredient worthy of the finest culinary masterpieces. Join us as we delve into the innovative practices, technological advancements, and economic implications of this rising trend that is reshaping the future of food.

The Evolution of Rice Milling: Transforming Grain into Culinary Delights

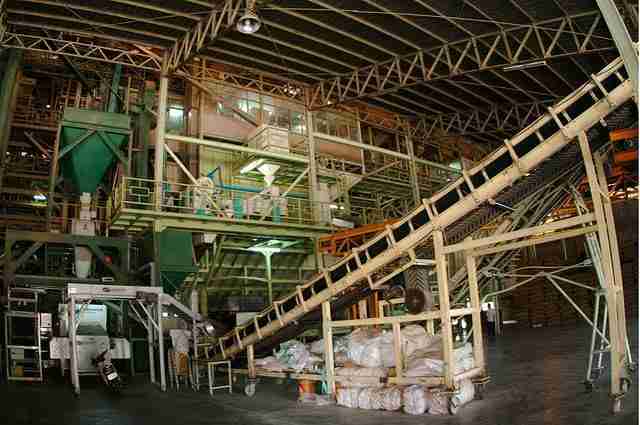

The journey of rice from field to table involves a magnificent transformation, where the humble grain undergoes a meticulous process to achieve its ultimate potential. Traditional methods, relying on manual labor and rudimentary tools, have evolved into sophisticated technology that enhances quality while ensuring efficiency. The rise of modern rice milling units incorporates not just advanced machinery but also scientific cultivation techniques that optimize grain yield and nutritional value. Today’s milling processes incorporate technologies such as integrated rice milling systems, where sorting, husking, and polishing occur under one roof, drastically reducing waste and saving time.

Moreover, the vitality of rice milling units extends beyond mere grain processing. These innovations directly contribute to sustainability and food security by maximizing output and minimizing environmental footprints. Key advancements include:

- Air Classification: Separates lighter impurities for cleaner grains.

- Color Sorting: Utilizes camera technology for sorting perfection, ensuring only the best grains reach consumers.

- Automated Quality Control: Implements algorithms to ensure consistent product quality.

| Innovation | Benefit |

|---|---|

| Husking Machines | Increased speed and reduced grain breakage. |

| Polishing Equipment | Enhanced appearance and taste without excessive loss of nutrition. |

| Packaging Technology | Prolongs shelf life and reduces spoilage. |

In this evolution, the role of rice milling has shifted from a simple processing function to that of an integral part of the agricultural and culinary landscape. The modern approach supports farmers by improving the financial returns on their labor, while consumers benefit from higher quality grains that enhance their culinary experiences. This blend of tradition and technology illustrates how far rice milling has come, proving that even the simplest of ingredients can achieve gourmet status through meticulous refinement.

Technological Advancements in Rice Milling: Enhancing Efficiency and Quality

The evolution of rice milling technology has revolutionized how rice is processed, marrying traditional techniques with cutting-edge innovations. Modern rice mills now utilize automated machinery that not only accelerates the milling process but also enhances the precision of grain grading. By integrating high-efficiency huskers, multifunctional whitening machines, and advanced sorting units, producers can ensure that each grain meets the highest quality standards. The result is a significant reduction in waste and energy consumption, making the entire process more sustainable and cost-effective compared to older methods.

Furthermore, advancements in data analytics and IoT integration are transforming rice milling from a conventional operation into a smart, interconnected system. Operators can now monitor the milling process in real-time, allowing for immediate adjustments based on environmental conditions and grain quality. This not only improves overall production efficiency but also enhances the end-product by ensuring that the texture, flavor, and nutritional value of the rice are preserved. Key benefits of these technological advancements include:

- Higher yield rates: Maximizes output from each batch.

- Consistent grain quality: Ensures uniformity across product lines.

- Energy savings: Reduces operational costs and carbon footprint.

- Real-time monitoring: Enhances decision-making with data-driven insights.

| Technology | Benefit |

|---|---|

| Automated milling systems | Increased efficiency and reduced labor costs |

| IoT sensors | Real-time quality control |

| Data analytics | Optimized milling parameters |

| Advanced sorting technology | Enhanced purity and grading accuracy |

Sustainable Practices in Rice Milling: Balancing Profitability and Environmental Responsibility

Embracing eco-friendly techniques in rice milling not only contributes to environmental sustainability but also enhances profitability for millers. By implementing energy-efficient machinery and reducing water usage in operations, milling units can significantly lower their operational costs while minimizing their ecological footprint. Modern milling technologies, such as solar-powered drying systems and biomass-based energy solutions, allow for a cleaner production process. Additionally, opting for recycling byproducts like rice husks for energy generation mitigates waste and leads to cost savings:

- Energy-efficient equipment reduces electricity costs.

- Water conservation methods lower utility expenses.

- Byproduct utilization transforms waste into profitable resources.

Moreover, rice milling units can engage in sustainable practices that appeal to environmentally-conscious consumers and their evolving demands. Incorporating organic certification processes and promoting transparent sourcing can create a new market niche that enhances brand loyalty. Understanding the value chains associated with sustainable rice production can also optimize distributions and logistics, contributing to extended profitability. The following table illustrates essential sustainable practices and their potential benefits for rice milling operations:

| Practice | Benefit |

|---|---|

| Use of renewable energy | Lower operational costs and reduced carbon footprint |

| Water-efficient milling | Conservation of resources and cost savings |

| Eco-friendly packaging | Attracts eco-conscious consumers |

Market Trends and Consumer Preferences: Adapting to the Gourmet Rice Revolution

The culinary landscape is evolving, with consumers increasingly leaning towards gourmet experiences that elevate traditional staples. This shift towards premium quality has fueled a surge in demand for specialty rice varieties, encouraging producers to innovate in rice processing and milling techniques. Today, consumers are not just looking for rice as a carbohydrate base; they seek products that offer distinct flavors, superior nutritional profiles, and authentic culinary experiences. Manufacturers have responded by implementing advanced milling units that preserve the unique qualities of each rice type, ultimately transforming an everyday ingredient into a gourmet staple.

To understand the underlying dynamics behind this gourmet rice revolution, consider the following trends that reflect changing consumer preferences:

- Increased Health Awareness: Rice fortified with nutrients or organic variants attract health-conscious buyers.

- Global Flavors: Varieties such as Jasmine, Basmati, and Arborio capture international culinary interests.

- Transparency in Sourcing: Consumers prefer brands that clarify their sourcing methods and environmental impact.

- Kitchen Innovations: Products that promote easy cooking and versatility are becoming highly sought after.

In response to these trends, rice milling units are now embracing technology that not only improves efficiency but also enhances the quality of finished products. By adopting precision milling processes, manufacturers can extract the best features from each rice grain, ensuring maximum flavor and texture. Below is a glimpse of the varieties gaining traction:

| Variety | Key Attributes | Consumer Appeal |

|---|---|---|

| Jasmine | Fragrant, soft, and sticky | Perfect for Southeast Asian dishes |

| Basmati | Long grains with aromatic flavor | Ideal for Indian cuisine |

| Arborio | Creamy texture for risottos | Italian culinary staple |

Future Outlook

As we conclude our exploration into the world of rice milling units and their transformation from simple grain processors to integral players in the gourmet food industry, it becomes clear that this evolution is more than just a trend—it’s a testament to the art and science of food production. The rise of rice milling units symbolizes a broader movement towards sustainability, quality, and culinary innovation. By embracing advanced milling techniques and prioritizing flavor profiles, these units are not only enhancing the grains we consume but are also enriching the gastronomic landscape.

As we move forward, the collaboration between millers, chefs, and consumers will undoubtedly shape the future of gourmet rice. This synergy stands to benefit regional economies, elevate culinary practices, and ignite a newfound appreciation for the humble grain. In this ever-evolving market, one thing is certain: the journey from grain to gourmet is just beginning, inviting us all to savor the rich narratives woven into each bowl of rice. Embrace the possibilities, and allow your palate to experience the full spectrum of flavors awaiting us in this dynamic field.