Exploring the Potential of a 2-Ton Rice Mill Plant Project

In an age where food security and sustainable agriculture are paramount, the humble grain of rice stands out as a staple that feeds billions around the globe. As nations strive for self-sufficiency and economic development, the importance of modernizing agricultural processes becomes increasingly evident. Enter the 2-ton rice mill plant project—a transformative venture that not only promises to enhance local rice production but also to empower farmers and invigorate rural economies. This article delves into the myriad possibilities inherent in setting up a 2-ton rice mill plant, exploring its economic viability, technological advancements, and the potential benefits it holds for communities and industries alike. Join us as we uncover the strategic significance and innovative solutions that lie within this seemingly simple yet profoundly impactful project.

Assessing the Economic Viability of a 2-Ton Rice Mill Plant Initiative

Conducting a thorough analysis of the economic potential of a 2-ton rice mill plant involves evaluating several critical factors that influence its feasibility. First and foremost, understanding the initial investment costs is essential. This includes not only the purchase of milling equipment but also expenses related to installation, permits, and other startup requirements. Additionally, we should factor in operational costs, such as labor, maintenance, utilities, and raw material procurement. The potential for profitability hinges on the balance of these expenditures against expected income derived from rice sales. Key components to consider in the financial analysis are:

- Market Demand: Assessing local and regional demand for milled rice.

- Competition: Evaluating similar enterprises in the vicinity to gauge the market saturation.

- Price Volatility: Analyzing rice pricing trends in the agricultural market.

Another aspect to consider is the establishment of operational efficiencies that can enhance profit margins. Factors such as crop yield projections, quality control measures, and potential partnerships with local farmers can positively impact productivity and reduce costs. Additionally, exploring government subsidies or support systems for agricultural ventures may provide further financial backing. A simplified breakdown of estimated revenues and costs over time is essential to visualize the project’s trajectory:

| Year | Estimated Revenue | Operational Costs | Net Profit |

|---|---|---|---|

| 1 | $50,000 | $40,000 | $10,000 |

| 2 | $60,000 | $45,000 | $15,000 |

| 3 | $70,000 | $50,000 | $20,000 |

Ultimately, a comprehensive economic evaluation embracing both qualitative and quantitative metrics will empower stakeholders to make informed decisions regarding the 2-ton rice mill plant initiative. By understanding these dynamics and preparing for potential challenges, investors can maximize both sustainability and profitability in this agricultural venture.

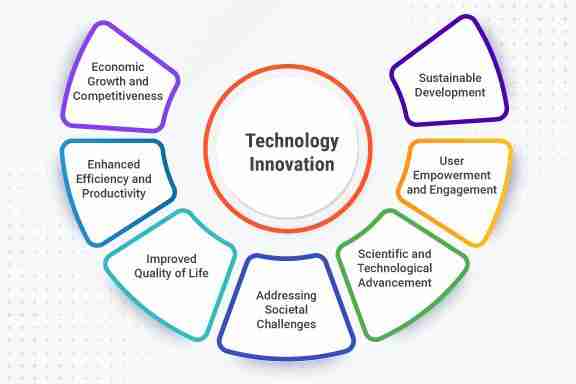

Technological Innovations Shaping Modern Rice Milling Processes

In recent years, advancements in technology have dramatically transformed rice milling processes, significantly improving efficiency and output quality for small and large-scale operations alike. The introduction of automated milling systems has streamlined production, reducing human error and minimizing labor costs. Some key innovations include:

- Smart Sensors: These devices monitor grain moisture levels, helping millers optimize drying processes.

- Energy-efficient Machines: New milling equipment is designed to consume less energy while still achieving high output rates.

- Real-time Data Analytics: Incorporating data analytics allows for better decision-making by providing insights into operational performance.

Moreover, the integration of IoT technology into rice milling plants has opened new frontiers for operational excellence. Plant managers now have the ability to remotely monitor equipment and processes, leading to timely maintenance and reducing downtime. Additionally, innovations such as eco-friendly milling practices are gaining traction, focusing on sustainable operations by minimizing waste and energy consumption. A comparative overview of conventional vs. innovative milling processes highlights these advancements:

| Aspect | Conventional Milling | Modern Innovations |

|---|---|---|

| Energy Consumption | High | Reduced by up to 30% |

| Labor Requirements | Manual, high | Automated, low |

| Moisture Control | Limited | IoT Sensors, precise |

Sustainable Practices for Efficient Rice Production and Processing

As the world increasingly prioritizes sustainability, rice production and processing can greatly benefit from innovative practices that not only enhance output but also conserve resources. Implementing integrated pest management (IPM) techniques helps minimize the use of harmful pesticides, effectively reducing chemical runoff into surrounding ecosystems. Likewise, adopting organic farming principles, such as crop rotation and green manuring, can strengthen soil health and promote biodiversity. Technologies like precision agriculture, which utilize GPS and IoT devices, allow for more targeted application of water and fertilizers, mitigating waste and optimizing yields.

In processing, energy-efficient milling techniques are essential for a sustainable rice industry. Operators can explore options like utilizing renewable energy sources, such as solar or biogas, for powering mills. Additionally, the recycling of by-products, including husks and bran, can be transformative. These by-products can be converted into biofuels or organic fertilizers, creating a circular economy within the rice processing sector. Furthermore, investing in modern milling equipment not only reduces energy consumption but also increases the quality of output, thereby enhancing market competitiveness.

| Practice | Description | Benefits |

|---|---|---|

| Integrated Pest Management | Utilizes natural pests and minimizes chemicals. | Enhances biodiversity and reduces health risks. |

| Precision Agriculture | Incorporates technology for efficient resource use. | Optimizes yield and conserves water and nutrients. |

| Renewable Energy | Utilizes solar or biogas to power milling processes. | Reduces carbon footprint and lowers operating costs. |

Navigating Regulatory Frameworks and Market Opportunities in Rice Milling

Establishing a rice milling plant requires a keen understanding of the various regulatory frameworks that govern the agricultural sector. Key regulations may vary significantly across regions, but they often include compliance with food safety standards, environmental regulations, and labor laws. Familiarizing oneself with these indispensable guidelines can pave the way for smoother operations. Researching local government initiatives not only enhances compliance but also unveils potential funding opportunities and incentives. By engaging with local agricultural boards, entrepreneurs can gain insights into:

- Permitting processes

- Incentives for sustainable practices

- Support programs for new ventures

Amidst the complexities of regulatory compliance, the landscape for market opportunities remains promising for rice milling ventures. Growing consumer demand for rice products—both locally and internationally—highlights the potential for profitability. By leveraging the right marketing strategies, millers can tap into diverse segments such as organic rice, pre-packaged rice products, and even rice by-products like bran oil. Analyzing current market trends can help project profitability and inform strategic decisions. A recent market overview might reveal essential insights such as:

| Optimum Market Segments | Projected Growth Rate |

|---|---|

| Organic Rice | 15% CAGR |

| Packaged Rice Products | 10% CAGR |

| Rice By-products | 8% CAGR |

In Summary

As we draw the curtains on our exploration of the 2-ton rice mill plant project, it’s evident that this initiative holds promise beyond mere numbers and machinery. The fusion of technology, sustainable practices, and community engagement positions this project as a beacon of innovation in the agricultural sector.

By harnessing local resources and catering to regional demands, a well-executed rice mill can not only uplift the economic landscape but also cultivate a sense of empowerment among farmers. As we look toward the future, the potential ripple effects of such an investment—be it through job creation, enhanced food security, or stronger local economies—are too significant to ignore.

In essence, this endeavor is more than just about processing rice; it’s about sowing the seeds of progress. As stakeholders consider their roles in bringing this vision to fruition, let us hope for a future where small-scale agricultural projects like this can thrive, creating a sustainable ecosystem that nurtures both people and the planet. The journey may be long, but with careful planning and dedication, the rewards could be transformative.