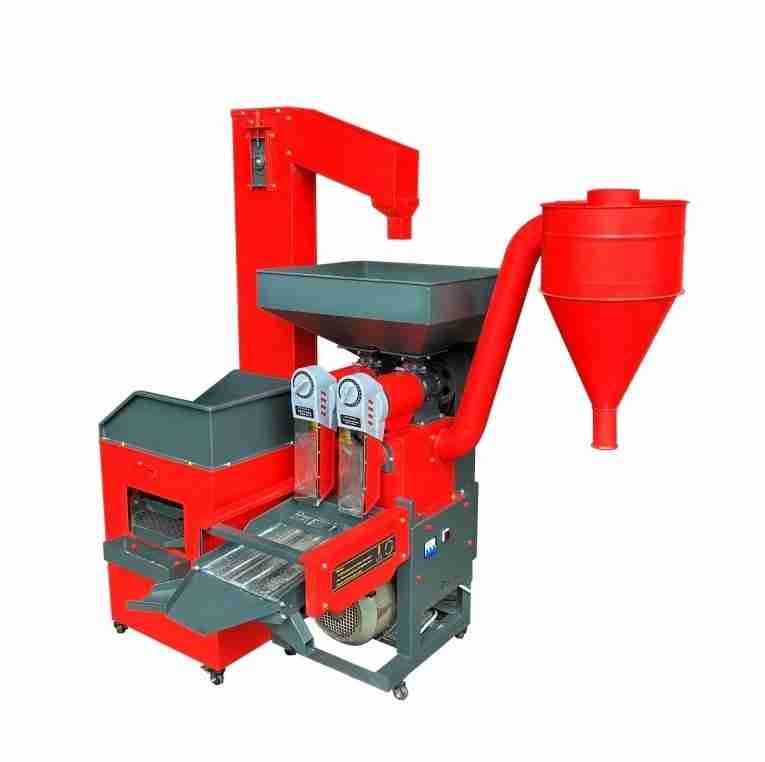

In a world where technology continually reshapes our daily routines, the culinary landscape is not left untouched. At the heart of this transformation lies a humble grain that has nourished civilizations for millennia: rice. For generations, the art of rice polishing has been a meticulous and often labor-intensive process, crucial to achieving the desired texture and quality for this staple food. However, with the advent of mini rice polisher machines, the traditional methods of polishing are being redefined. These compact, efficient devices are not only streamlining production but are also promising to enhance flavor and nutritional value, catering to the needs of both small-scale producers and home cooks alike. As we explore the rise of these innovative machines, we will uncover how they are unlocking precision and perfection in rice preparation, revolutionizing the way we approach one of the world’s most beloved foods.

The Evolution of Rice Polishing Technology

The journey of rice polishing technology has witnessed remarkable advancements, steadily shifting from traditional methods to highly specialized machinery. Initially, rice was polished using manual techniques involving stone grinders or wooden mortars, which, while effective, were labor-intensive and often resulted in uneven polishing. As the demand for polished rice surged, manufacturers sought more efficient solutions. The introduction of mechanical polishing machines in the early 20th century marked a significant turning point, enabling consistent results and increased production capabilities.

Today, mini rice polisher machines embody the latest innovations in this domain. These compact yet powerful machines leverage precision engineering to achieve superior polishing quality while minimizing waste. Their design typically features adjustable polishing settings, which allow users to customize the degree of polish according to specific requirements. Significant benefits of these modern machines include:

- Energy Efficiency: Reducing power consumption without compromising performance.

- Enhanced Control: User-friendly interfaces for precise adjustments.

- Sustainable Practices: Increased recovery of rice bran and less rejection of usable grain.

| Feature | Traditional Methods | Mini Rice Polishers |

|---|---|---|

| Polishing Precision | Inconsistent results | Highly customizable |

| Labor Intensity | High | Low |

| Energy Use | Higher consumption | Optimized for efficiency |

Benefits of Mini Rice Polishers for Small Scale Operations

In the evolving landscape of food processing, mini rice polishers have emerged as game-changers for small scale operations. Their compact size allows entrepreneurs to fit them into any workspace, making them an ideal choice for those with limited space. Moreover, their efficiency in polishing rice enhances productivity without compromising on quality. By processing smaller batches, businesses can maintain higher control over their product quality, ensuring that every grain meets the standards that customers expect. This precision fosters customer loyalty and can significantly boost market reputation.

Another noteworthy benefit lies in the cost-effectiveness of mini rice polishers. These machines consume less power compared to larger counterparts, resulting in reduced operational costs. Additionally, the straightforward design means lower maintenance expenses, making them more accessible for small business owners. Beyond savings, mini rice polishers offer various features tailored to meet specific needs, such as adjustable polishing times and different polishing modes. This versatility allows operators to customize the process, catering to diverse consumer preferences and enhancing the overall product appeal.

Key Features to Look for in Your Next Mini Rice Polisher

When searching for the perfect mini rice polisher, there are several key features to consider that will enhance both performance and user experience. One of the most important aspects is the polishing technology. Machines that utilize advanced polishing techniques, like high-frequency vibrations or gentle air circulation, often yield better results while preserving the nutritional value of the rice. Additionally, look for adjustable polishing settings that allow you to customize the degree of polish based on your specific preferences and rice type, ensuring that you achieve the ideal texture and shine every time.

Another crucial factor is the size and capacity of the mini rice polisher. Consider the amount of rice you typically process; models with larger hoppers can save time and prevent frequent refills. Moreover, ease of maintenance and cleaning should not be overlooked. A design that allows for simple disassembly and features such as non-stick surfaces or detachable components can significantly streamline the cleaning process. To give you a clear overview, here’s a quick comparison of some popular features:

| Feature | Importance |

|---|---|

| Polishing Technology | Enhances texture and preserves nutrients |

| Adjustable Settings | Allows customization for different rice types |

| Capacity | Saves time by reducing refill frequency |

| Ease of Cleaning | Streamlines maintenance routine |

Best Practices for Maintenance and Efficiency Enhancement

To maximize the performance of mini rice polisher machines, it is essential to adopt preventive maintenance strategies. Regular checks on critical components such as the polishing chamber and the rotating brushes can help identify wear and tear before it leads to significant breakdowns. Scheduled cleaning is also vital, as rice husk and dust can accumulate, hindering the machine’s efficiency. Implementing a daily inspection checklist can streamline this process:

- Check for any unusual noise during operation

- Monitor the temperature of the polishing chamber

- Inspect the integrity of the rotating brushes

- Ensure that electrical connections are secure

In addition to regular maintenance, optimizing operational practices can lead to substantial improvements in efficiency. One effective strategy is to conduct staff training sessions focused on the best use of the machinery. This not only promotes a deeper understanding of the machines but also encourages adherence to optimal operating parameters. To visualize the efficiency enhancements, consider the following comparison of operational variables:

| Operational Variable | Before Optimization | After Optimization |

|---|---|---|

| Energy Consumption | 100 kWh | 80 kWh |

| Polishing Time | 60 minutes | 45 minutes |

| Material Loss | 5% | 2% |

Through these practices, machine uptime can be increased, operational costs can be reduced, and the quality of the polished rice can be enhanced, ultimately leading to greater profitability in rice milling operations.

In Summary

As we step into an era where efficiency and quality are paramount, the emergence of mini rice polisher machines stands as a testament to innovation in the agricultural sector. These compact powerhouses not only enhance the grains’ appearance and nutritional value but also empower small-scale farmers and processors to achieve results previously deemed impossible. By systematically unlocking the potential of polished rice, they are transforming traditional practices and paving the way for a more sustainable future.

the rise of mini rice polishers reflects a broader trend towards precision and accessibility in food production. As technology continues to evolve, so too will the opportunities for growers around the globe to refine their craft. With every grain polished to perfection, we find ourselves one step closer to a world where quality and sustainability are seamlessly intertwined. As we look ahead, it will be exciting to witness the next chapter in this unfolding narrative, where innovation continues to enhance our agricultural landscapes, one rice grain at a time.