In an era where quality dictates market success, the agricultural sector is continuously seeking ways to enhance the standards of its products. Among the innovations transforming the landscape of grain processing is the Jet Rice Polisher, a sophisticated machine that marries cutting-edge technology with traditional grain handling practices. This remarkable equipment not only refines rice to a pristine polish but also plays a pivotal role in elevating the overall quality of grain. In this article, we will delve into the mechanics of the Jet Rice Polisher, explore its myriad benefits, and examine how it contributes to creating a superior final product that meets the demands of both consumers and producers alike. Join us as we uncover the precision behind this essential tool and its impact on the future of grain quality.

Innovative Technology Behind Jet Rice Polishers

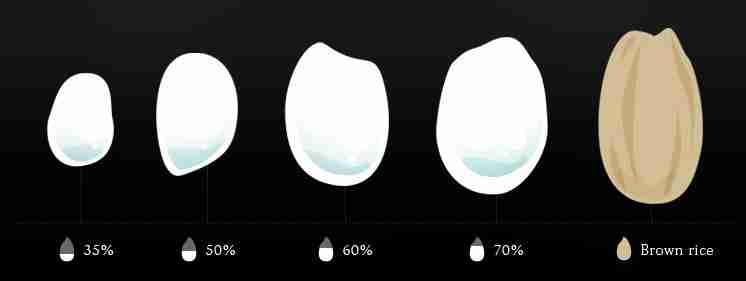

The evolution of grain processing has reached new heights with the introduction of innovative technology in Jet Rice Polishers. These advanced machines leverage cutting-edge engineering to enhance the quality of rice while preserving its nutritional value. Unlike traditional methods, Jet Rice Polishers utilize a combination of high-velocity air and precision polishing mechanisms to achieve superior polishing results. This technology not only ensures a uniform appearance but also enhances the overall quality and taste of the rice, making it more appealing to consumers.

Key features of modern Jet Rice Polishers include:

- Eco-friendly Design: Reducing energy consumption while maintaining performance.

- Automated Control Systems: Allowing for precise adjustments in the polishing process.

- Advanced Sensor Technology: Monitoring grain quality in real-time, ensuring optimal results.

- Reduced Grain Breakage: Enhancing yield through gentle polishing methods.

To illustrate the benefits of using Jet Rice Polishers, a simple comparison table highlights the differences between conventional and modern techniques:

| Aspect | Conventional Polishers | Jet Rice Polishers |

|---|---|---|

| Energy Efficiency | Low | High |

| Grain Quality | Moderate | Superior |

| Grain Breakage | High | Minimal |

| Process Automation | Manual | Automated |

Maximizing Grain Quality Through Precision Engineering

In the competitive world of grain production, achieving superior quality requires an unwavering commitment to precision and innovation. The introduction of advanced machinery, such as jet rice polishers, epitomizes this dedication. These machines utilize high-velocity jets of air, enhancing the polishing process without compromising the integrity of the grains. By meticulously removing impurities and maximizing shine, jet rice polishers not only elevate the aesthetic appeal of the grains but also play a significant role in their overall nutritional value. The precision in engineering allows for minimal grain breakage, ensuring that producers maintain the highest standards for marketability.

Key features of jet rice polishers include:

- Adjustable Polishing Settings: Tailored parameters to match varying grain types, ensuring optimal results.

- Energy Efficiency: Innovative designs reduce energy consumption while elevating performance.

- User-Friendly Interface: Simplified controls allow operators to make quick adjustments for consistent quality.

- Advanced Airflow Technology: Guarantees uniform treatment across all grains, preventing any cold or hot spots that may affect quality.

To better understand the impact of jet rice polishers on grain quality, consider the following comparison table:

| Feature | Traditional Polishers | Jet Rice Polishers |

|---|---|---|

| Grain Breakage Rate | High | Low |

| Energy Consumption | Moderate | Low |

| Consistency of Finish | Variable | High |

| Ease of Use | Complex | User-Friendly |

This comparison underscores the transformative potential of precision engineering in enhancing grain quality, marking a significant advancement in agricultural technology. By leveraging the capabilities of jet rice polishers, operators can ensure that their products meet both market demands and consumer expectations, ultimately leading to greater profitability and sustainability in grain production.

Best Practices for Effective Rice Polishing

Effective rice polishing is essential for enhancing the grain’s marketability and consumer appeal. To achieve optimal results, operators should focus on maintaining uniform pressure and consistent airflow throughout the polishing process. This will ensure that all grains are polished evenly, preventing any damage to fragile kernels. Additionally, monitoring the temperature during polishing can help mitigate any risk of overheating, which can lead to quality loss and nutritional deterioration. Consider embracing technology for tracking important metrics, such as moisture content and polishing time, which are critical for achieving the best results.

Furthermore, employing a multi-step polishing technique can further improve grain quality. This approach includes an initial coarse polishing, followed by more refined polishing stages. Operators should also prioritize regular maintenance checks on polishing machines to ensure they are functioning at peak efficiency. Key practices include:

- Regularly cleaning polishing chambers to avoid residue build-up.

- Examining polishing pads for wear and replacing them as needed.

- Utilizing appropriate polishing agents to protect the grain’s surface.

| Polishing Stage | Purpose | Main Focus |

|---|---|---|

| Coarse Polishing | Initial removal of outer husk | Minimize kernel damage |

| Medium Polishing | Smoother grain texture | Consistent polishing pressure |

| Fine Polishing | Achieve high luster | Optimal temperature control |

The Future of Grain Processing with Jet Rice Polishers

In an era where consumer demands for high-quality grains are on the rise, the introduction of jet rice polishers represents a significant leap forward in grain processing technology. These machines utilize high-velocity air streams, which precisely remove impurities and enhance the quality of rice without compromising its nutritional integrity. This innovative method not only improves the appearance of rice but also boosts its shelf life and cooking quality, meeting the expectations of both manufacturers and discerning consumers alike. The surge in automation and digitization in food processing is making these advanced machines more accessible, allowing for wider implementation across various mill sizes and types.

The versatility of jet rice polishers is noteworthy, as they can cater to different types of grains while providing consistent results. The advantages include reduced processing times, higher output quality, and environmentally friendly operations. Key features that set these machines apart include:

- Precision control: Tailored settings for varying grain types.

- Energy efficiency: Lower energy consumption compared to traditional methods.

- Minimized waste: Efficient removal of husk and bran while preserving kernel integrity.

The future landscape of grain processing will likely be shaped by these advancements, with ongoing innovations promising even greater efficiencies. Below is a simplified overview of their impact on grain processing:

| Aspect | Traditional Methods | Jet Rice Polishers |

|---|---|---|

| Processing Time | Longer | Reduced significantly |

| Grain Quality | Variable | Consistently high |

| Energy Use | High | Lower |

| Waste Produced | Higher | Minimized |

As the industry continues to evolve, embracing technology like jet rice polishers becomes essential for staying competitive and delivering superior products to the market.

To Wrap It Up

As we draw the curtain on our exploration of the Jet Rice Polisher, we are reminded of the delicate balance between tradition and innovation in the grain processing industry. This remarkable machine stands as a testament to the power of precision engineering, enhancing the quality of rice while preserving the rich heritage associated with its cultivation. In a world where consumer demands are ever-evolving, the Jet Rice Polisher not only meets these challenges but also elevates the standards of grain refinement. With its ability to deliver enhanced purity and appeal, this technology ensures that each grain is not just a staple, but a testament to the meticulous craft behind its production. As we continue to seek advancements in agricultural practices, the Jet Rice Polisher shines as a beacon of progress, reminding us that the journey of grain—from field to table—can always be improved with a little innovation and a touch of care.