Unveiling Paddy Processing: From Field to Finely Milled Rice

In the lush green expanse of rural landscapes, rice paddies sway gently in the breeze, waiting for the harvest that will transform them from vibrant fields into a staple that graces tables around the globe. The journey from paddy to plate is a captivating process, steeped in tradition and innovation. Each step along this path plays a crucial role in ensuring that grains are not only nourishing but also of the highest quality. This article delves into the intricate world of paddy processing, tracing its transformation from humble sprout to perfectly milled rice. Join us as we explore the stages of cultivation, harvesting, and milling, uncovering the skilled hands and advanced techniques that contribute to this essential food source. Together, we will reveal the artistry and science behind a crop that feeds billions, illuminating the often-overlooked journey that begins in the field and ends in our kitchens.

Understanding the Paddy Lifecycle: Cultivation to Harvest

Paddy cultivation is a meticulous process that begins with selecting the right variety of rice seeds, tailored to the climate and soil conditions of the region. Once seeds are sown, they germinate into seedlings that thrive in flooded fields, which serve not only as a protective barrier against weeds but also as a source of essential nutrients. Key stages in this lifecycle include:

- Seedling Development: Initially, rice seeds are nurtured in nurseries where they grow to about 5-10 cm tall.

- Transplanting: Once the seedlings mature, they are carefully uprooted and transplanted into prepared paddy fields.

- Growth Period: This crucial phase allows the plants to flourish over 3-4 months, collecting sunlight and water.

- Ripening: As the grains mature, the fields transform into golden vistas, signaling that harvest time is near.

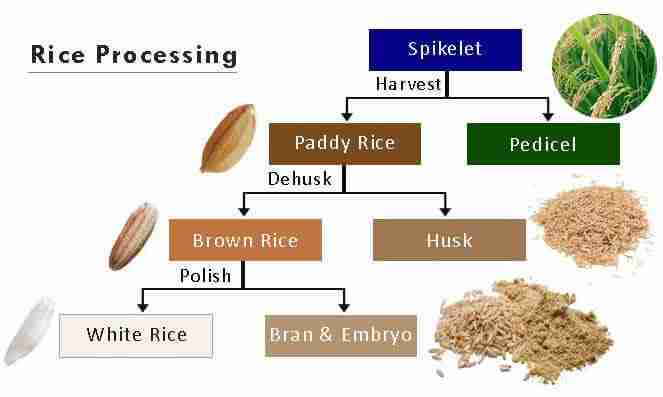

When harvest arrives, careful timing ensures that the grains are at their optimal moisture content, ready for cutting. After harvesting, the paddy undergoes drying to reduce moisture levels, preventing spoilage. Following this, the grains are transported to mills where they are hulled and polished, transforming rough paddy into the shiny, white rice that graces dining tables worldwide. The processing stages can be summarized as:

| Processing Stage | Description |

|---|---|

| Drying | Reduces moisture content for better storage. |

| Hulling | Removes the outer husk from the paddy. |

| Polishing | Gives rice its final luster and removes bran. |

Critical Steps in Paddy Processing: Ensuring Quality and Efficiency

In the journey from paddy to polished rice, each stage of processing plays a pivotal role in determining the quality of the final product. The initial step involves harvesting, where meticulous attention is paid to the timing, as this can significantly impact grain quality. Following this, the threshing process separates the kernels from the stalks, an act that requires the right equipment to minimize damage. Subsequently, the drying phase is crucial; improper moisture levels can lead to spoilage or reduced quality during storage. During this stage, careful monitoring is essential to ensure that the grains reach an optimal moisture content. Continuous quality checks during these phases establish a strong foundation for the later stages of milling and marketing.

With the paddy properly prepared, the focus shifts to milling, where the transformation into rice occurs. A well-designed milling system operates efficiently to produce high-quality end products. Key components include parboiling, which enhances the nutritional profile, and hulling, which removes the outer husk without adversely affecting the grains. Following milling, grading is performed to classify the rice based on size and quality, making it easier for both producers and consumers to evaluate the product. A systematic approach to these processes not only enhances efficiency but also ensures that each batch meets safety and quality standards, fostering trust among consumers.

| Processing Step | Key Focus | Quality Indicator |

|---|---|---|

| Harvesting | Timing & Technique | Grain Integrity |

| Threshing | Equipment Selection | Kernels Separation |

| Drying | Moisture Control | Prevent Spoilage |

| Milling | Technology & Method | Mineral Retention |

| Grading | Size & Quality Sorting | Market Value |

Innovative Technologies in Milling: Enhancing Texture and Flavor

The world of milling has experienced a significant transformation with the advent of innovative technologies designed to enhance both texture and flavor in rice processing. Advanced milling machines now incorporate features such as precision grinding and multi-stage processing, which not only optimize yield but also ensure that the final product retains its natural aroma and nutritional value. By utilizing AI-driven analytics, mill operators can monitor the quality of rice in real-time, making instantaneous adjustments to milling parameters that enhance the taste profile and texture.

Moreover, these cutting-edge technologies allow for greater customization in the milling process. Producers can now fine-tune variables such as temperature, pressure, and retention time, resulting in perfectly milled rice tailored to specific culinary needs. Emerging flavor infusion techniques incorporate natural flavors and essential oils during the milling process, offering gourmet options that cater to a diverse consumer palate. The fusion of technology with traditional practices continues to redefine the possibilities in rice milling, delivering products that not only meet but exceed modern consumer expectations.

| Technology | Impact on Milling |

|---|---|

| Precision Grinding | Improves texture and consistency |

| AI-Driven Analytics | Ensures quality control and efficiency |

| Flavor Infusion | Enhances taste with natural elements |

Sustainability in Rice Production: Best Practices for a Greener Future

In the journey from field to finely milled rice, implementing sustainable practices is essential for minimizing environmental impact and enhancing resilience. Sustainable rice production emphasizes crop rotation, which can improve soil health and reduce dependency on chemical fertilizers. Farmers are adopting integrated pest management (IPM), a strategy that reduces pesticide use by utilizing biological controls and crop varieties that resist pests. Additionally, water management techniques play a crucial role. By employing methods such as alternate wetting and drying, farmers can conserve water resources while maintaining paddy yields.

Moreover, the transformation of paddy to rice involves various steps where sustainability can be enhanced. The milling process, for example, can benefit from renewable energy sources, which dramatically decrease carbon emissions. Moreover, the use of by-products from milling, like rice husk and straw, can be optimized for energy production or as organic fertilizer, closing the waste loop. Sustainable packaging and distribution further help to reduce the overall carbon footprint associated with rice. Key practices include:

- Efficient use of fertilizers: Targeting nutrient application and using organic alternatives.

- Harnessing renewable energy: Solar panels for processing facilities, reducing reliance on fossil fuels.

- Minimizing food waste: Promoting ‘whole grain’ rice options and proper storage techniques.

| Practice | Impact |

|---|---|

| Crop Rotation | Improves soil fertility |

| IPM | Reduces pesticide usage |

| Water Management | Conserves vital resources |

| Renewable Energy in Milling | Decreases carbon emissions |

Concluding Remarks

As we draw the curtains on our journey through the intricate world of paddy processing, it’s clear that this humble grain encapsulates a remarkable story of transformation. From the lush green fields where it sways in the breeze to the meticulously controlled milling facilities that yield the fine rice gracing our tables, every step in the paddy processing journey is a testament to human ingenuity and agricultural diligence.

The delicate balance of tradition and technology plays a vital role, ensuring that we not only preserve the rich heritage of rice cultivation but also meet the demands of a growing global population. Each grain embodies the hard work of farmers, the expertise of millers, and the cultural significance that rice holds in various societies.

As we savor the end product, let us appreciate the unseen labor and innovation that has brought us from paddy to polished rice. The path from field to table is not merely a logistical transition; it is a narrative woven with history, sustainability, and a promise of nourishment that continues to evolve. In exploring this journey, we deepen our connection to the food we consume and the stories behind it—stories that deserve recognition and respect.