In the world of agriculture, where tradition meets innovation, the landscape of rice production is witnessing a transformative shift. Paddy processing, a critical step in converting harvested rice into the staple we know, has long required a delicate balance of time, labor, and technology. As demand for rice continues to rise globally, so too does the need for more efficient processing solutions. Enter the age of advanced paddy processing machines—a realm where cutting-edge technology and innovative design converge to redefine efficiency. This article delves into the future of paddy processing machinery, exploring how these advancements not only streamline production but also contribute to sustainability and food security. Join us as we unlock the potential of modern mechanization and uncover the vital role it plays in shaping the future of rice cultivation.

Exploring Innovative Technologies in Paddy Processing Equipment

As the world shifts towards sustainable agricultural practices, the advent of cutting-edge technologies in paddy processing equipment is redefining efficiency and productivity. Innovations such as automated rice milling systems, which utilize advanced sensors and AI-driven algorithms, ensure precise quality control while significantly reducing labor costs. These machines not only enhance the milling process but also minimize wastage of grains, contributing to a more sustainable food supply chain.

Furthermore, the integration of smart technologies such as IoT (Internet of Things) capabilities has revolutionized how farmers monitor and manage their paddy processing operations. With real-time data analytics, farmers can make informed decisions about optimal milling times and processing methods, leading to increased overall yield. Some key features of these futuristic machines include:

- Automated quality assessment: Using imaging technology to assess grain quality.

- Energy efficiency: Minimizing energy consumption with eco-friendly designs.

- User-friendly interfaces: Simplified controls for ease of use.

- Predictive maintenance: Reducing downtime with advanced maintenance alerts.

| Technology | Benefits |

|---|---|

| Automated Milling Systems | Higher efficiency and reduced labor costs. |

| IoT Integration | Real-time monitoring and management. |

| Energy-Efficient Designs | Lower operating costs and environmental impact. |

| Smart Quality Control | Enhances product consistency and customer satisfaction. |

Enhancing Sustainability through Modern Processing Techniques

As the agriculture sector shifts towards sustainable practices, innovative processing techniques are at the forefront of enhancing efficiency and reducing waste. Modern paddy processing machines are designed not only to maximize yield but also to minimize environmental impact. With the integration of advanced technologies, these machines have revolutionized the traditional practices, fostering a cleaner production cycle. Key features of these innovations include:

- Energy Efficiency: Reduced energy consumption through optimized machinery and automation.

- Waste Reduction: Effective separation and utilization of by-products, promoting a circular economy.

- Precision Processing: Enhanced accuracy in grain handling minimizes damage and loss.

Moreover, adopting smart processing techniques facilitates real-time monitoring and data analysis, helping farmers make informed decisions that positively impact both their productivity and sustainability goals. The following table highlights the comparative benefits of traditional versus modern paddy processing techniques:

| Aspect | Traditional Processing | Modern Processing |

|---|---|---|

| Energy Use | High consumption | Optimized efficiency |

| Waste Management | Significant waste | Recycled by-products |

| Processing Time | Long duration | Quick turnaround |

Such advancements not only ensure better quality grains but further contribute to the overall environmental sustainability of agricultural practices. As these machines become more accessible, they pave the way for a promising future that aligns agricultural efficiency with sustainable development goals.

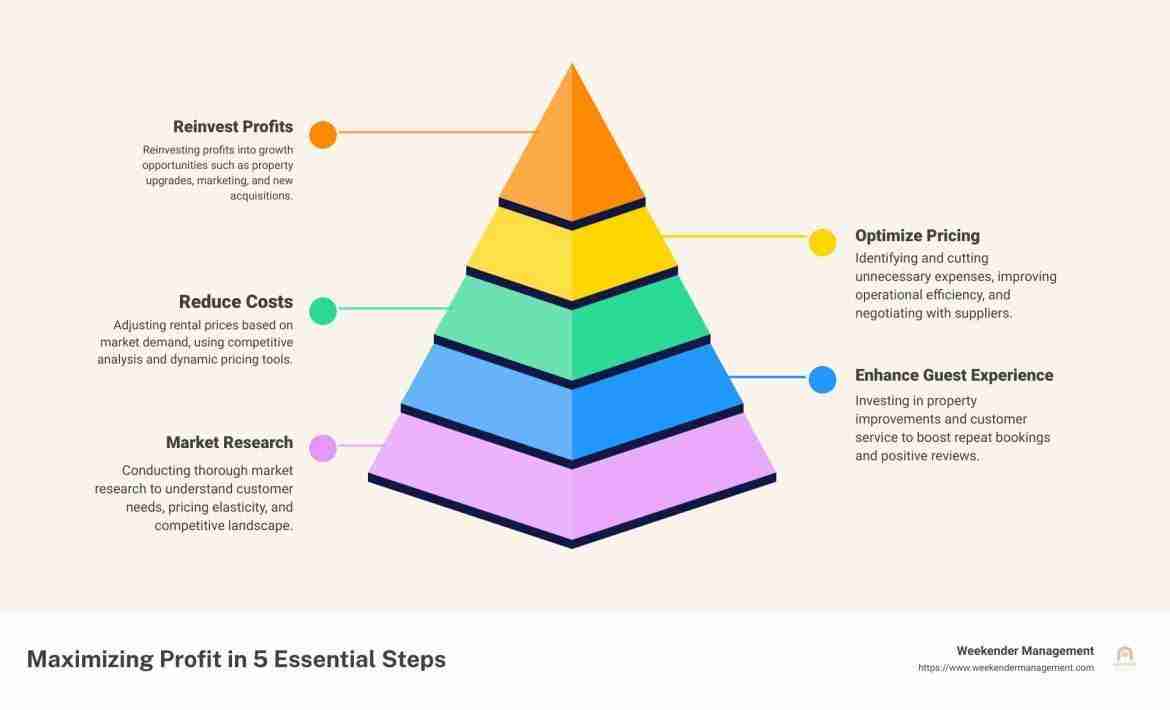

Maximizing Productivity with Automation and Smart Solutions

In the fast-evolving landscape of paddy processing, integrating automation is not merely an option, but a necessity for staying competitive. Innovations in technology, such as advanced sensors and machine learning algorithms, empower processors to enhance their operations, ultimately yielding higher quality products. By automating repetitive tasks, stakeholders can invest their time and resources into strategic planning and quality control. The shift towards machines that can monitor environmental conditions, assess grain quality, and perform real-time adjustments significantly reduces waste and optimizes productivity. Consider the following benefits gained through automation:

- Enhanced Speed: Automation facilitates faster processing times, allowing businesses to meet increasing market demands.

- Consistency: Machines ensure uniformity in processing, maintaining the quality across batches.

- Resource Efficiency: Smart solutions help in minimizing the use of water, energy, and other essential resources.

- Data-Driven Insights: Automated systems collect valuable data that drives informed decisions for future operations.

Moreover, the incorporation of Internet of Things (IoT) technology in paddy processing machines allows for seamless connectivity and control, significantly enhancing both operational oversight and flexibility. Operators can monitor the processing environment remotely, making real-time adjustments to optimize performance. A structured approach to implementing these smart solutions provides robust advantages. Below is a simple comparison of traditional vs. automated paddy processing:

| Feature | Traditional Processing | Automated Processing |

|---|---|---|

| Processing Speed | Slow | Fast |

| Labor Intensive | High | Low |

| Quality Control | Manual Checks | Real-time Monitoring |

| Waste Generation | Higher | Lower |

Incorporating these advanced systems not only streamlines the entire production process but also sets a standard for sustainability in agricultural practices. Adopting automated technology in paddy processing fosters an innovative approach to enhance productivity while ensuring the methodical management of resources.

Investing in Future-Ready Paddy Processing Infrastructure

In a world increasingly driven by technological advancements, investing in cutting-edge paddy processing infrastructure is imperative for both efficiency and sustainability. Modernizing the processing facilities not only reduces waste but also maximizes output. By integrating state-of-the-art machinery, paddy processors can expect to achieve significant improvements in their operational workflows. The benefits of this investment include:

- Enhanced Productivity: Automated systems increase throughput while maintaining consistent quality.

- Energy Efficiency: Advanced machines consume less energy, significantly lowering operational costs.

- Waste Reduction: Refined processes ensure minimal loss during milling and sorting.

- Labor Optimization: Reduced manual handling allows workers to focus on more strategic roles.

Moreover, adopting a future-ready mindset towards infrastructure entails considering sustainable practices that align with environmental goals. This includes utilizing eco-friendly technologies and materials in the construction and operation of processing facilities. Key elements to consider in this transition are:

| Aspect | Current Approach | Future Solution |

|---|---|---|

| Energy Source | Fossil Fuels | Renewable Energy |

| Waste Management | Landfill | Recycling & Reuse |

| Water Usage | High Consumption | Water Recycling Systems |

By embracing these transformative changes, stakeholders not only enhance their competitive edge but also ensure that they are contributing positively to the environment and future generations. The vision for paddy processing infrastructure is clear: it must evolve into a model of operational excellence, sustainability, and resilience.

In Summary

As we stand at the intersection of tradition and innovation, the evolution of paddy processing machines holds the key to unlocking new efficiencies in the agricultural sector. Embracing advanced technology not only streamlines production but also improves sustainability, ensuring that our rice harvests are managed thoughtfully and effectively for generations to come.

The future beckons with promises of reduced waste and enhanced capacity, steering us toward a more resilient food system. Whether you are a farmer, an investor, or a technology enthusiast, the advancements in paddy processing present an opportunity to engage with an industry ripe for transformation. As we explore these innovations and their implications, it becomes clear that the journey to efficiency is just beginning. Together, let us navigate this evolving landscape, where each stride forward brings us closer to a prosperous and sustainable future in agriculture.