Transforming Rice: The Essential Role of Paddy Processing Plants

In the heart of many agricultural landscapes, a humble grain silently plays a pivotal role in shaping food systems, economies, and traditions around the world: rice. From the verdant paddies where it is cultivated to the bustling markets where it is sold, the journey of rice is a testament to human ingenuity and the intricate dance of nature and nurture. Yet, behind this seemingly straightforward grain lies a complex web of processes that bring rice from field to fork. Central to this transformation are paddy processing plants—modern marvels that elevate the raw, harvested grain into a refined product fit for consumption. As we delve into the essential functions of these facilities, we will explore not just their technological innovations and operational intricacies, but also their profound impact on food security, economic stability, and sustainability in rice-producing regions. Join us on this enlightening journey, as we uncover how paddy processing plants are not merely factories, but vital catalysts in the journey of rice from country to kitchen.

Understanding the Paddy Processing Journey: From Field to Table

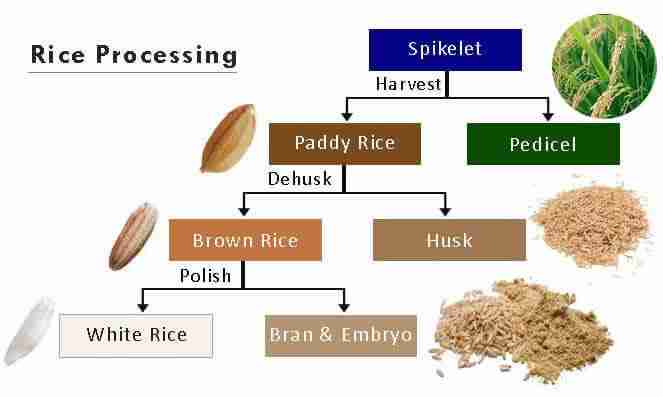

Paddy processing is a complex and essential journey that transforms harvested grains into the rice we consume daily. After the paddy is harvested, it enters a meticulous process involving several stages. Initially, the paddy goes through cleaning to remove dirt, dust, and impurities, ensuring that only high-quality grains are processed. Following this, the paddy is subjected to parboiling, a unique method that involves soaking and steaming the grains. This step not only enhances the nutritional value of the rice but also improves the texture and makes it easier to mill.

Once parboiling is complete, the drying phase kicks in, where the moisture content is reduced to optimal levels, preventing spoilage and ensuring longevity. The next crucial step is the milling process, where the husk and bran layers are removed to yield white rice. This stage involves a delicate balance; removing too much bran can eliminate vital nutrients, while leaving too much can affect the rice’s taste and appearance. the processed rice is packaged and prepared for distribution, ready to make its way to tables around the world. The entire journey not only showcases the incredible transformation of paddy to rice but also highlights the importance of precision and care in maintaining quality throughout each stage.

| Processing Stage | Description |

|---|---|

| Cleaning | Removing dirt and impurities. |

| Parboiling | Soaking and steaming for enhanced nutrition. |

| Drying | Reducing moisture content to prevent spoilage. |

| Milling | Removing husk and bran to yield white rice. |

| Packaging | Preparing rice for distribution. |

Innovative Technologies Shaping Efficient Rice Processing

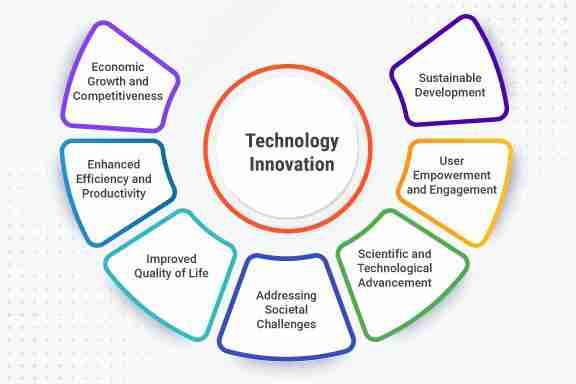

In the quest for enhanced efficiency in rice processing, a range of innovative technologies has emerged, revolutionizing how paddy is transformed into consumable rice. Among these advancements, the adoption of automated milling systems stands out. These systems utilize smart sensors that not only monitor grain quality but also adjust the milling parameters in real-time, ensuring minimal breakage and maximizing yield. Additionally, AI-driven analytics are enabling processors to predict demand patterns and optimize production schedules, which significantly reduces waste and enhances profitability.

Moreover, the integration of solar energy systems within paddy processing plants is gaining momentum. These systems are crucial, especially in regions where traditional energy sources are unreliable or expensive. By harnessing solar power for various processes such as drying and ventilation, processing plants can achieve substantial cost savings while also contributing to a more sustainable operation. Other notable innovations include the use of biotechnology for pest and disease management, which ensures that the rice produced is not only high in quality but also environmentally friendly.

| Technology | Benefits |

|---|---|

| Automated Milling Systems | Enhances yield, reduces breakage |

| AI-driven Analytics | Optimizes production, reduces waste |

| Solar Energy Systems | Lower costs, sustainable operations |

| Biotechnology for Pest Management | Environmentally friendly, high-quality rice |

Sustainability Practices in Paddy Processing Plants

In the quest for greener operations, paddy processing plants are embracing a variety of sustainability practices that not only minimize their ecological footprint but also contribute to the welfare of local communities. These facilities are increasingly investing in technologies that enhance energy efficiency and reduce waste. For instance, by employing biomass energy systems, they can convert rice husks and straw into usable energy, thereby reducing dependence on fossil fuels. Such initiatives not only lower operational costs but also promote a circular economy by repurposing by-products that would otherwise be discarded.

Furthermore, many plants are prioritizing water conservation through advanced irrigation techniques and wastewater management systems. Techniques such as drip irrigation and recycling wastewater ensure that water is used judiciously, thus mitigating the adverse effects of overuse on local water resources. Additionally, paddy processing plants are increasingly adopting methods to ensure their sourcing is both ethical and sustainable, working closely with local farmers to promote organic cultivation practices. These efforts empower farmers and contribute to a more resilient agricultural ecosystem.

Enhancing Quality Standards: Best Practices for Rice Transformation

To achieve optimal results in rice transformation, it is vital to implement a series of best practices that ensure the highest quality standards. Key considerations include:

- Regular Maintenance: Conducting routine checks and maintenance of machinery to prevent breakdowns that can lead to product loss.

- Quality Control Protocols: Establishing stringent quality control measures at every stage of processing to monitor impurities, moisture content, and overall grain quality.

- Staff Training: Providing continuous training programs for employees on the latest techniques and technology, allowing for improved efficiency and product handling.

Furthermore, integrating technology into paddy processing plants can drastically enhance operational excellence. Consider the adoption of:

| Technology | Benefit |

|---|---|

| Automated Sorting Systems | Improved accuracy in separating high-quality grains from inferior ones. |

| Moisture Sensors | Ensures optimal storage conditions, reducing spoilage and enhancing shelf life. |

| Real-time Monitoring Software | Allows for immediate adjustments in processing, ensuring consistency in quality. |

To Wrap It Up

As we conclude our exploration of paddy processing plants, it becomes evident that these facilities are the unsung heroes in the journey from field to table. Transforming raw, unassuming grains into a staple that nourishes millions worldwide requires not only advanced technology but also a deep understanding of agricultural practices and consumer needs. The intricate processes that take place within these plants underscore their essential role in meeting global food demands while ensuring quality and sustainability.

As we look toward the future, the significance of investing in and modernizing paddy processing plants cannot be overstated. With the ongoing challenges of climate change and population growth, these facilities will play a crucial role in bolstering food security and adapting to an ever-evolving agricultural landscape.

In recognizing the importance of paddy processing, we celebrate not just the grains but the dedicated minds and methods behind their transformation. Let us continue to appreciate the journey of rice, from the paddies that cradle its beginnings to the tables where it serves as a comforting staple, reminding us of the interconnectedness of our food systems and the vital roles each player within them contributes.