In the lush green fields of rice paddies, where golden grains sway gently in the breeze, an intricate process begins long before the final product graces our plates. The journey of paddy processing plants is a testament to the age-old relationship between nature and technology, where the raw harvest is transformed into the staple food that nourishes millions. This article explores the multifaceted world of grain processing, delving into the innovative methods and machinery that breathe life into harvested rice, as well as the challenges and triumphs faced by those who dedicate their lives to this vital industry. From the clattering of huskers to the whirr of polishing machines, join us as we unravel the story behind the transformation of paddy—a journey that is as much about tradition as it is about progress.

The Evolution of Paddy Processing Technologies

The journey of paddy processing has seen remarkable transformations, evolving from simple manual techniques to sophisticated industrial operations. In the past, farmers relied on traditional methods, which included hand-threshing and water-powered rice mills. These practices, while effective at small scales, were labor-intensive and time-consuming. With the advancement of technology, mechanical innovations began to shape the landscape. Today, automated milling systems, multi-functional paddy huskers, and integrated rice processing units have streamlined the entire process, significantly increasing efficiency and productivity.

The integration of technology not only hastened production but also enhanced the quality of the final product. Modern processing plants utilize advanced machinery equipped with optical sorters that ensure purity by removing impurities and unwanted grains. Moreover, the implementation of digital monitoring systems allows real-time tracking and management of production metrics, ensuring optimal milling conditions and minimal waste. The transition from rudimentary methods to these high-tech solutions reflects a broader trend in agricultural processing, one that prioritizes sustainability, quality, and economic viability.

| Paddy Processing Method | Characteristics | Advantages |

|---|---|---|

| Traditional Hand-Threshing | Labor-intensive, low-output | Cost-effective for small farms |

| Mechanical Milling | High efficiency, automated | Increased yield, consistent quality |

| Integrated Processing Units | Multi-stage processing, real-time monitoring | Maximized production, reduced waste |

Sustainable Practices in Modern Grain Processing

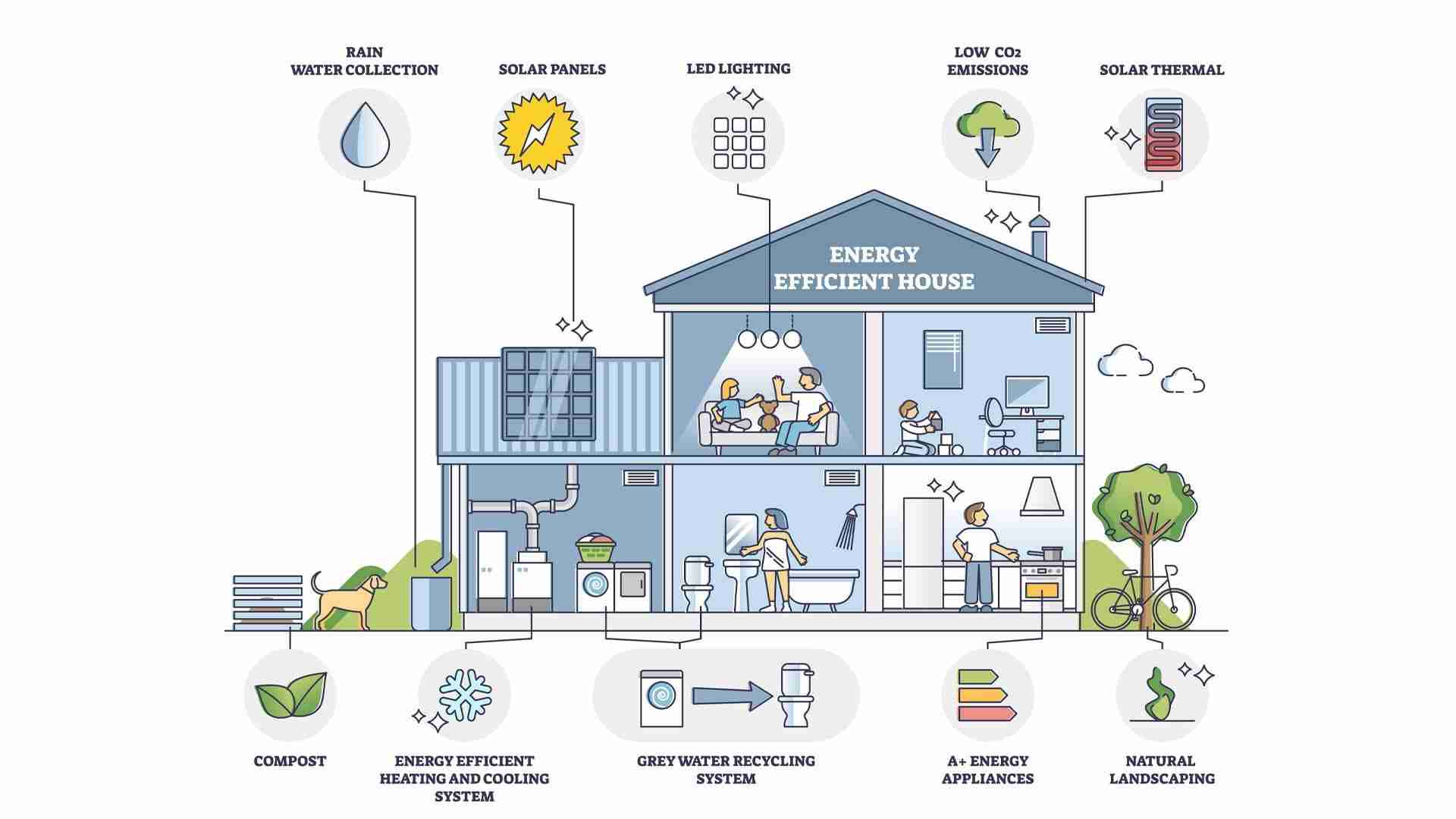

The modern grain processing industry is witnessing a transformation driven by sustainability, emphasizing efficiency and ecological responsibility. Paddy processing plants are adopting innovative methods to minimize waste and energy consumption while enhancing productivity. By integrating renewable energy sources such as solar and bioenergy, these facilities are not only reducing their carbon footprints but also achieving cost savings. This shift towards sustainability is often supported by technology that allows for real-time monitoring and adjustments, ensuring optimal performance in resource utilization.

Moreover, sustainable practices extend beyond energy use to encompass water conservation and waste management. Paddy processing plants are now deploying advanced technologies for water recycling, significantly reducing their freshwater intake while maintaining production levels. Additionally, many facilities are finding value in what was once considered waste. Byproducts like husks and bran are being transformed into valuable commodities, including animal feed and biochar, thereby fostering a circular economy. This thoughtful approach not only enhances resource efficiency but also contributes to a more resilient agricultural sector.

Maximizing Efficiency Through Innovative Grain Handling

In the realm of grain handling, the integration of advanced technologies has become a cornerstone for optimizing operational efficiency. By utilizing automated systems and smart sensors, facilities can now monitor grain quality and flow in real-time, reducing the risk of spoilage and ensuring the highest standards are met. Here are some of the notable benefits of innovative grain handling practices:

- Real-time Monitoring: Enables prompt adjustments to mitigate issues before they escalate.

- Automated Handling: Reduces labor costs and human error, streamlining the entire packaging process.

- Data Analytics: Empowers decision-makers with insights derived from historical and predictive analytics.

Additionally, the role of sustainable practices within grain handling cannot be overlooked. Implementing energy-efficient machinery and waste-reduction techniques not only lowers operational costs but also aligns with global sustainability goals. The juxtaposition of efficiency and environmental stewardship is reflected in the latest advancements:

| Advancement | Benefits |

|---|---|

| Energy-efficient dryers | Lower fuel consumption and reduced energy costs. |

| Automated moisture management | Enhanced grain preservation and reduced spoilage rates. |

| Eco-friendly packaging solutions | Minimized environmental impact and improved market appeal. |

Through the continuous evolution of technology and a commitment to sustainable practices, paddy processing plants can position themselves for a future that embraces both productivity and environmental responsibility. By adopting innovative handling methods, these facilities pave the way for more resilient agricultural supply chains that benefit not just farmers, but also consumers around the world.

Quality Control and Safety Standards in Paddy Milling

In the intricate world of paddy milling, ensuring that every grain is processed with precision is paramount. The implementation of stringent quality control measures begins from the moment paddy enters the milling facility. Each batch undergoes a meticulous inspection to identify impurities, moisture levels, and overall grain quality. Key steps in this process include:

- Pre-Milling Inspection: Assessing the quality of raw paddy through visual and mechanical methods.

- Moisture Measurement: Using calibrated tools to ensure optimal moisture content for milling.

- Grain Sampling: Collecting samples from various points within the batch for comprehensive evaluation.

Equally critical to the processing journey is the adherence to safety standards aimed at protecting both the workforce and the product. Safety protocols range from routine equipment checks to systemic hygiene practices, ensuring that all processes align with regulatory guidelines. Noteworthy safety measures include:

- Regular Equipment Maintenance: Routine checks to prevent machinery malfunctions.

- Workplace Hygiene: Implementation of cleanliness routines to avoid contamination.

- Employee Training: Educating workers on safety practices and emergency protocols.

| Quality Control Measure | Description |

|---|---|

| Grain Purity Tests | Ensuring that the grain meets specific standards free from foreign materials. |

| Color Testing | Visual checks to guarantee the rice’s uniform color indicating quality. |

The Conclusion

As the sun sets on the vast fields of golden rice, the journey of paddy processing plants unfolds—a transformative odyssey from humble grain to vital sustenance. Each step in this intricate process not only enhances the quality of our food but also elevates the livelihoods of countless farmers and workers along the way. From milling to packaging, these plants embody the delicate balance between tradition and technology, preserving ancient practices while embracing innovation for a sustainable future.

In a world where food security is paramount, understanding the intricate mechanisms of paddy processing becomes essential. It reminds us that behind every grain, there is a story of hard work, perseverance, and dedication. As we reflect on this journey, we are inspired to appreciate the multifaceted role that paddy processing plants play in our daily lives and the global economy.

Ultimately, the transformation of grain is more than just a mechanical process; it is a testament to our interconnectedness and the shared responsibility we hold in nurturing the food systems that sustain us. As we move forward, let us honor and support these facilities, ensuring they continue to thrive and innovate in the face of evolving challenges. After all, the journey of grain is a journey of hope—driving us towards a more resilient and food-secure future.