In the hushed embrace of dawn, as the first whispers of sunlight kiss the verdant fields, a symphony of transformation begins within the heart of a paddy processing factory. Here, grains that have soaked up the earth’s essence embark on a remarkable journey from field to table. This article invites you to step inside this bustling hub of activity, where the fusion of tradition and technology converges to elevate humble rice into a culinary staple cherished across the globe. As we delve into the intricate processes, the dedicated hands that cultivate and refine, and the stories woven into every grain, we uncover the vital role that paddy processing plays in feeding the world and sustaining communities. Join us as we explore the unseen intricacies of an industry that breathes life into grain, transforming it into nourishment that connects cultures and generations.

Harnessing Technology for Efficient Paddy Processing

In the quest for optimizing paddy processing, technology plays a pivotal role, breathing new life into traditional methods. Automated machines now take the place of manual labor, enhancing productivity while minimizing human error. Key innovations include:

- Modern Milling Equipment: Advanced milling techniques ensure higher extraction rates while preserving grain quality.

- Sorting Machines: Utilizing optical sensors, these machines detect and separate defective grains at lightning speed.

- Moisture Control Systems: Precision moisture meters ensure that grains are processed at optimal levels, preventing spoilage and enhancing shelf life.

Furthermore, the integration of data analytics platforms offers valuable insights into the processing cycle. By monitoring real-time statistics, such as production rates and energy consumption, factory managers can make informed decisions that promote efficiency and reduce waste. The impact of such systems can be visualized with data tables:

| Parameter | Before Automation | After Automation |

|---|---|---|

| Processing Time (hrs) | 12 | 8 |

| Grain Loss (%) | 10 | 2 |

| Energy Consumption (kWh) | 150 | 100 |

This data illustrates the transformative impact of technological innovations within paddy processing facilities, showcasing a future where efficiency is not just a goal but a reality. By embracing cutting-edge solutions, these facilities enhance their output and contribute to a more sustainable food production system.

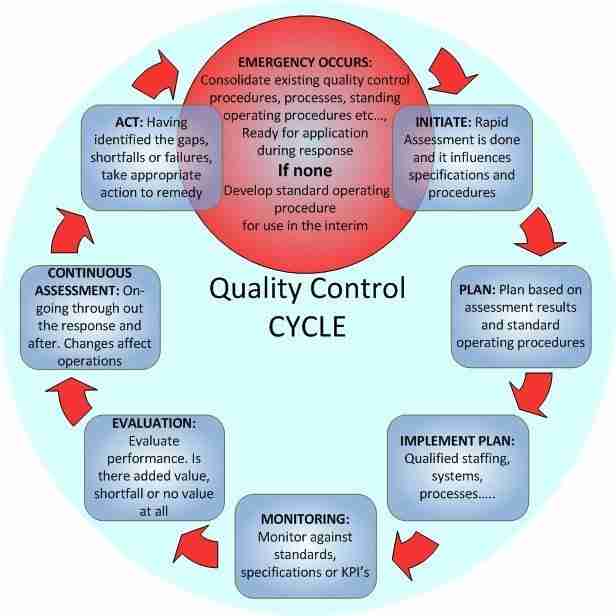

Quality Control Measures in Modern Grain Facilities

Quality control is the backbone of any paddy processing factory, ensuring that the final product meets both safety standards and consumer expectations. Modern grain facilities employ a multi-faceted approach to quality assurance, utilizing state-of-the-art technology alongside traditional practices. Critical checkpoints throughout the processing journey are established to monitor and maintain the quality of paddy rice. These measures include:

- Visual Inspection: Trained personnel routinely conduct visual assessments of the grains to identify any foreign materials or defects.

- Moisture Testing: High-tech moisture meters assess the moisture content, which is crucial for preventing spoilage.

- Contaminant Testing: Samples are taken for laboratory analysis to detect potential contaminants such as aflatoxins and heavy metals.

To further enhance the quality control process, many facilities implement comprehensive tracking systems that document each batch’s processing history. This creates a transparent workflow that enables swift identification of issues should they arise. Additionally, quality control is supported by regular training workshops for staff, focusing on best practices in handling, processing, and storage. The following table illustrates various stages and their corresponding quality checks:

| Processing Stage | Quality Check | Frequency |

|---|---|---|

| Cleaning | Visual Inspection | Every Batch |

| Drying | Moisture Testing | Hourly |

| Milling | Contaminant Testing | Daily |

These rigorous quality control measures not only safeguard the grain’s integrity but also build consumer confidence in the brand’s commitment to excellence.

Sustainable Practices for Eco-Friendly Paddy Production

In the quest for eco-friendly paddy production, farmers are increasingly turning to innovative practices that nurture the environment while ensuring a bountiful harvest. One such method is crop rotation, where farmers alternate paddy cultivation with legumes or other crops to enhance soil fertility and disrupt pest cycles. Another sustainable approach is the implementation of integrated pest management (IPM), which emphasizes the use of natural predators, resistant crop varieties, and organic pesticides to minimize environmental impact. Additionally, employing drip irrigation not only conserves water but also provides crops with the precise hydration they need, reducing runoff and soil erosion.

Another key aspect of sustainable paddy production involves the careful management of organic fertilizers. By utilizing compost and other organic materials, farmers enrich the soil without relying on chemical inputs that could harm local ecosystems. Implementing conservation tillage further helps preserve soil structure and enhance biodiversity. To visualize the effectiveness of these sustainable methods, consider the following table showcasing the benefits of various eco-friendly practices on yield, soil health, and water conservation:

| Practice | Benefits |

|---|---|

| Crop Rotation | Improves soil fertility and reduces pests |

| Integrated Pest Management | Minimizes chemical use and promotes biodiversity |

| Drip Irrigation | Conserves water and reduces soil erosion |

| Organic Fertilizers | Enhances soil health without harming ecosystems |

| Conservation Tillage | Preserves soil structure and supports biodiversity |

Navigating Market Trends: Strategies for Paddy Industry Success

In the ever-evolving landscape of the grain market, adaptability is key. One effective strategy for paddy processors is to invest in technology that enhances efficiency and quality. Upgrading machinery to include advanced sorting and milling technologies ensures that the highest quality of paddy is produced, which is essential for standing out in a competitive market. Additionally, adopting data analytics can provide valuable insights into market trends, helping businesses to respond swiftly to fluctuations in demand and pricing.

Another crucial element for sustaining success in the paddy industry is fostering strong partnerships throughout the supply chain. Building alliances with local farmers, logistics providers, and even retailers can forge a reliable network that mitigates risks and maximizes potential profits. Implementing sustainable practices not only attracts environmentally-conscious consumers but also reduces operational costs in the long run. Key actionable points include:

- Collaboration with farmers to ensure a consistent supply of high-quality paddy.

- Adopting eco-friendly practices that appeal to market trends and consumer preferences.

- Training and development for workers to keep pace with innovations in processing.

In Summary

As we conclude our journey through the intricate world of paddy processing, it becomes evident that this seemingly straightforward operation encompasses a tapestry of innovation, craftsmanship, and sustainability. Each grain that passes through the factory’s machinery tells a story—of farmers’ hard work, of technology transforming raw potential into nutritious sustenance, and of communities relying on this meticulous process to nourish their daily lives.

The paddy processing factory stands not only as a hub of activity but also as a testament to humanity’s relationship with agriculture. The harmonious interplay of tradition and modern techniques ensures that the grains we consume today are not merely products, but stories of culture and survival, delicately transformed from field to table.

In our ever-evolving world, the significance of understanding such processes cannot be underestimated. Each mouthful of rice carries with it the history of an industry poised to adapt and thrive amid challenges. As we leave the factory’s heart, we carry with us a newfound appreciation for the journey of grain—a humble yet vital ingredient that stitches together the fabric of our global community.