In the heart of countless kitchens around the world lies a staple food that binds cultures and nourishes families: rice. As one of the most consumed grains globally, rice has transcended borders and traditions, becoming a symbol of sustenance and culinary delight. However, the journey from paddy fields to the dinner table is not as simple as it seems. In recent years, the landscape of rice production has witnessed a quiet yet profound transformation, driven by advancements in technology. Enter the realm of paddy processing machines—innovative tools that are revolutionizing the way rice is processed and packaged. This article delves into the crucial role these machines play in enhancing efficiency, ensuring quality, and promoting sustainability in an industry that feeds billions. Explore how the fusion of tradition and technology is reshaping the future of rice production, and discover the hidden mechanics that are making every grain count.

The Evolution of Paddy Processing Techniques and Their Impact on Rice Quality

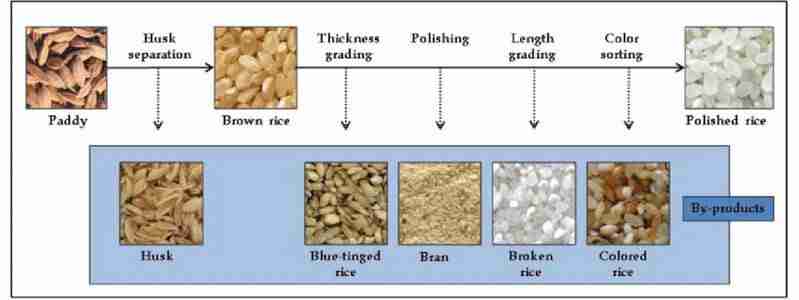

The journey of rice from paddy to plate is a fascinating transformation shaped by numerous advancements over the years. Traditional hand processing methods, once the norm, often resulted in variations in rice quality, making it challenging to meet the demands of a growing population. The introduction of paddy processing machines has been a game-changer, revolutionizing the efficiency and consistency of rice production. With these machines, processing time has been significantly reduced, allowing for a quicker turnaround. Moreover, innovations such as modern huskers, polishers, and color sorters minimize grain breakage and impurities, leading to higher quality products that meet stringent market standards.

Additionally, the impact of mechanized processing on rice quality cannot be overstated. The precision of these machines ensures that grains are processed uniformly, enhancing their appearance and nutritional value. Significant benefits include:

- Improved milling efficiency: Higher recovery rates of whole grains.

- Enhanced flavor retention: Proper husking and polishing techniques preserve essential oils.

- Reduced contamination: Automated systems limit human contact, decreasing the risk of dirt and foreign materials.

By balancing traditional methods with technological advancements, paddy processing has evolved into a sophisticated art that not only boosts productivity but also elevates the quality of rice produced worldwide.

Key Technologies Transforming Efficiency in Rice Production

The integration of advanced technologies in rice production has dramatically enhanced operational efficiency, especially in the realm of paddy processing. Modern paddy processing machines equipped with cutting-edge features allow farmers to streamline their workflows and maximize output. These machines not only save significant time but also minimize labor costs, which is crucial in an industry that relies heavily on manual labor. Among the innovations, the following technologies stand out:

- Automated Sorters: Utilizes advanced sensors to separate grains based on quality.

- Silage Mixers: Efficiently blends paddy straw with other nutrients for better feed.

- Integrated Rice Millers: Combines several processing stages into a single machine, reducing handling and transition time.

Furthermore, the use of data-driven approaches such as precision agriculture is transforming how farmers monitor rice paddies and processing outputs. By employing IoT devices, farmers can gather and analyze data in real-time, enabling them to make informed decisions that enhance yield and quality. The following table illustrates the improvements in efficiency attributed to these technologies:

| Technology | Efficiency Gain | Impact on Cost |

|---|---|---|

| Automated Sorters | Up to 30% faster sorting | Reduces labor costs by 20% |

| Integrated Rice Millers | Processing time cut by 40% | Minimizes energy consumption |

| IoT Monitoring | Real-time data reduces waste by 15% | Enhances resource allocation, lowering costs |

Sustainability in Paddy Processing: Innovations for a Greener Future

Sustainability in paddy processing is at the forefront of technological innovation, radically transforming how rice is milled and processed. With a focus on reducing waste and maximizing efficiency, new machinery is leading the charge towards greener practices. These advanced paddy processing machines are equipped with features that prioritize energy conservation, minimize water usage, and reduce emissions. By implementing smart technologies, such as sensors and automation systems, these machines not only optimize workflows but also ensure more sustainable operations throughout the production cycle.

Among the noteworthy innovations are machines designed to utilize by-products of rice milling, turning what was previously considered waste into valuable resources. For instance, the hulls and bran can be converted into eco-friendly fertilizer or bioenergy, promoting circular economic practices. Additionally, advancements in water recycling systems are enabling facilities to reuse water within their processes, drastically reducing overall consumption. The table below highlights key features of modern paddy processing machines that contribute to sustainability:

| Feature | Benefit |

|---|---|

| Energy-efficient motors | Lower power consumption, reduced carbon footprint |

| Water recycling systems | Minimized water waste, enhances sustainability |

| Biomass utilization | Converts waste to energy or fertilizer, promoting circular economy |

Choosing the Right Paddy Processing Machines for Diverse Agricultural Needs

When it comes to optimizing rice production, selecting appropriate paddy processing machines is crucial. Farmers must assess their specific needs and capacity to ensure that the machinery aligns with their operational goals. Considerations like the size of the farm, volume of paddy to be processed, and types of rice produced play a pivotal role in this decision-making process. The range of available machines includes huskers, hullers, and milling machines, each designed to tackle different stages of the processing journey. These tools not only enhance efficiency but also improve the quality of the final product, making it essential to match the right equipment with the intended harvesting scale.

Investing in technology that caters to diverse agricultural requirements can lead to significant improvements in productivity and profit margins. Here are some key features to prioritize while choosing the right machines:

- Versatility: Machines that can handle different rice varieties.

- Energy Efficiency: Minimal energy consumption with maximum output.

- Ease of Maintenance: Simple parts accessibility for timely servicing.

- Automation: Advanced technology for reducing manual labor.

By assessing these features, farmers can make informed choices and invest wisely in equipment that will serve their operational frameworks effectively, thereby revolutionizing their rice production capabilities.

The Way Forward

the evolution of paddy processing machines marks a significant turning point in the world of agriculture and food production. By enhancing efficiency, reducing labor costs, and ensuring high-quality output, these innovative technologies not only boost the livelihood of farmers but also contribute to global food security. As we continue to embrace advancements in this field, it is essential to consider their impact on sustainability and environmental practices. The future of rice production lies in our ability to harmonize tradition with innovation, ensuring that the staple remains a vital source of nourishment for generations to come. By revolutionizing rice processing, we pave the way for a greener, more productive agricultural landscape, one grain at a time.