In a world where food security is becoming increasingly paramount, the agricultural landscape stands at a pivotal juncture. Among the myriad crops that sustain populations globally, rice holds a special position as a staple food for more than half of the planet’s inhabitants. Yet, as the demand for rice continues to soar amid growing populations and changing dietary preferences, traditional farming methods are being stretched to their limits. Enter the revolution in rice farming: the rise of paddy processing machines. These innovative machines are not just enhancing efficiency; they are transforming the entire agricultural paradigm. This article delves into the technological advancements that are reshaping paddy processing, offering a glimpse into how these machines are bridging the gap between age-old practices and the relentless march of modernity in agriculture. Join us as we explore the potential of paddy processing machines to revolutionize farming practices, improve yield quality, and ultimately secure the future of rice production.

Harnessing Technology for Enhanced Efficiency in Paddy Processing

Advancements in technology have significantly transformed the landscape of paddy processing, introducing innovative machines that streamline operations and maximize output. The integration of automated systems and smart technology allows producers to enhance their efficiency by reducing the labor-intensive aspects of traditional methods. Here are a few notable technologies that are playing a pivotal role in this evolution:

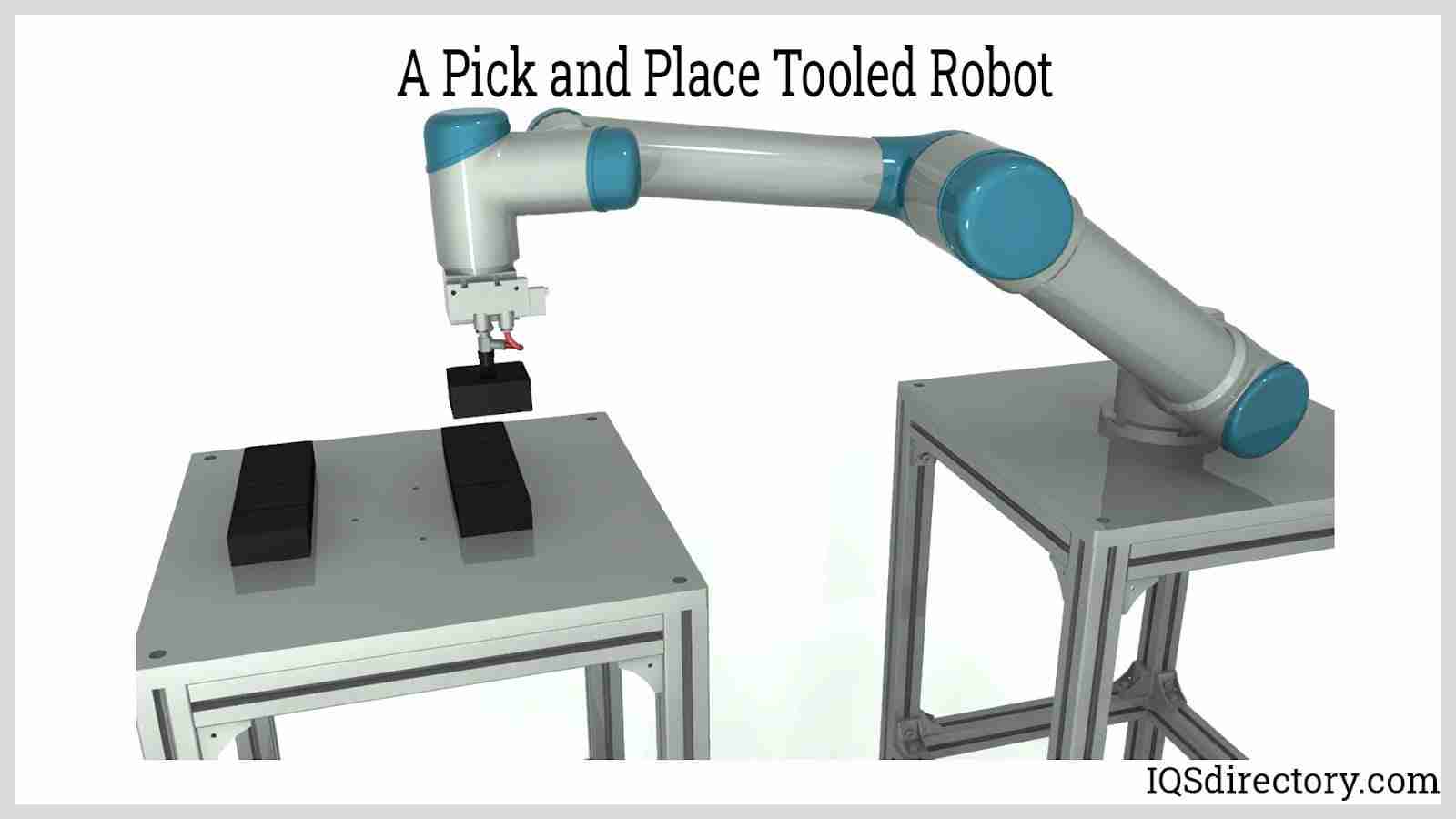

- Automatic Rice Mill Machines: These machines combine multiple processing stages—from husking to polishing—into one seamless operation, drastically reducing manual labor.

- Sensors and IoT Devices: By monitoring humidity and temperature, these tools help in maintaining optimal conditions for rice storage, thus minimizing spoilage and maximizing quality.

- Traceability Software: Implementing this software allows farmers to track their produce from field to market, improving accountability and assisting consumers in making informed choices.

Furthermore, the introduction of solar-powered machines and energy-efficient designs is helping to mitigate costs associated with paddy processing. This not only benefits producers by minimizing overhead but also promotes sustainable farming practices. Below is a simple overview of the energy savings associated with various technologies:

| Technology | Energy Savings (%) |

|---|---|

| Solar-Powered Mill | 30% |

| Automated Sorting Machine | 25% |

| High-Efficiency Dehusker | 20% |

By harnessing these technologies, farmers not only enhance efficiency but also contribute to a more sustainable agricultural future, bridging the gap between tradition and modernity.

The Impact of Automated Systems on Crop Yield and Quality

The integration of automated systems in agriculture, particularly in paddy processing, has ushered in a new era of efficiency and sustainability. With the introduction of advanced machinery, farmers now experience enhanced productivity and reduced labor costs. These machines are designed to optimize various stages of paddy processing, ensuring that the grain is cleaned, hulled, and polished with minimal manual intervention. The benefits are evident:

- Increased Crop Yield: With precise mechanisms, automated systems help in achieving higher yields by maximizing the output during the milling process.

- Improved Quality: Automation reduces the chances of human error, leading to consistent grain quality and better marketability.

- Time Efficiency: Faster processing times allow farmers to turn around their produce quickly, reaching consumers sooner.

Furthermore, these innovations not only enhance the quantitative aspects of production but also focus on the qualitative dimensions. Automation enables farmers to employ specific processing techniques that enhance the nutritional profile of paddy, ensuring that the end product meets consumer demands. The integration of sensors and data analytics further allows for real-time monitoring and adjustments during processing, which can lead to an even higher standard of output.

| Aspect | Before Automation | After Automation |

|---|---|---|

| Processing Time | Up to 48 hours | Less than 12 hours |

| Labor Requirement | 10 workers | 3 workers |

| Quality Consistency | Variable | High |

Sustainable Practices in Paddy Processing Machinery Development

In recent years, the push for eco-friendly technologies has reached the forefront of paddy processing machinery development, emphasizing the need for sustainable practices that minimize waste and reduce environmental impact. Innovations in machine design have focused not only on efficiency but also on material usage, opting for biodegradable or recyclable components wherever possible. Key sustainable practices include:

- Energy-efficient designs: Machinery that requires less energy to operate not only saves costs but also decreases carbon footprints.

- Waste recycling systems: Integrated systems that convert by-products from rice processing into bio-fertilizers or biofuels contribute to a circular economy.

- Water conservation techniques: New technologies are being developed to recycle water used in processing, thus conserving this vital resource.

Moreover, many manufacturers are adopting life cycle assessment (LCA) methods during the design phase to evaluate the environmental impact of their products from conception to disposal. The integration of smart technologies helps in optimizing resources further, allowing for real-time monitoring and adjustments that promote sustainable operations. A comparative analysis of traditional versus modern paddy processing machinery showcases these advancements:

| Feature | Traditional Machinery | Modern Sustainable Machinery |

|---|---|---|

| Energy Consumption | High | Low |

| Waste Management | Minimal | Comprehensive Recycling |

| Water Usage | Excessive | Optimized and Recycled |

Future Trends in Agricultural Machinery: A Focus on Innovations in Paddy Processing

As the demand for high-quality rice continues to soar globally, innovations in paddy processing machinery are paving the way for more efficient and sustainable agricultural practices. Advanced technologies such as Automation and Artificial Intelligence (AI) are being integrated into paddy processing to optimize productivity and enhance precision. These machines are designed to reduce human labor, providing farmers with a much-needed respite while ensuring that paddy quality is uncompromised. Key developments include the emergence of smart harvesters, which are equipped with sensors to assess ripeness and adjust their harvesting techniques accordingly, thereby minimizing crop wastage.

The incorporation of sustainable practices within this sector cannot be overlooked. Modern paddy processing machines are increasingly being designed to reduce energy consumption and lower carbon footprints. Moreover, innovations like biomass energy utilization and waste recycling systems are transforming byproducts into valuable resources, promoting a circular economy within paddy farming. Below is a table highlighting some revolutionary features found in cutting-edge paddy processing equipment:

| Feature | Description |

|---|---|

| Smart Sensor Technology | Automatically detects optimal harvesting conditions to enhance yield. |

| Energy Efficiency | Utilizes renewable energy sources to minimize environmental impact. |

| Automated Sorting | Ensures high-quality grain by sorting based on size and weight. |

| Remote Monitoring | Cloud connectivity allows real-time tracking of machinery performance. |

Final Thoughts

As we stand on the brink of a new agricultural era, the emergence of paddy processing machines marks a significant turning point in the farming landscape. These innovative technologies not only optimize efficiency but also empower farmers to elevate their productivity and enhance the quality of their crops. By streamlining post-harvest processes and reducing labor intensity, these machines are setting the stage for a more sustainable and economically viable agricultural future.

The rise of paddy processing machines is more than just a technological advancement; it’s a movement towards revitalizing rural economies, ensuring food security, and responding to the ever-increasing demands of a global population. As these machines continue to evolve, they promise to reshape how we think about cultivation, harvesting, and processing, paving the way for a more resilient industry.

In harnessing the power of mechanization, we take a crucial step towards not only transforming traditional practices but also nurturing innovation and sustainability in agriculture. As we witness this revolution unfold, one thing is clear: the future of paddy processing lies in our hands, guided by the relentless pursuit of progress and the unwavering spirit of the farming community.