In the verdant fields where the golden grains of rice sway gently in the breeze, a silent revolution is taking root. As the sun rises on agricultural innovation, mini rice mill plants are emerging as beacons of efficiency and sustainability, reshaping the landscape of rice production. These compact milling solutions are not just enhancing productivity; they are empowering smallholder farmers, invigorating local economies, and paving the way for a more resilient food system. This article explores the transformative impact of mini rice mills, delving into their role in improving harvest yields, reducing post-harvest losses, and fostering community-driven development. Join us as we uncover the stories and technologies driving this rise, illuminating a path toward a more prosperous agricultural future.

The Evolution of mini rice mill Plants in Modern Agriculture

The landscape of agricultural production has witnessed a seismic shift with the introduction of mini rice mill plants, significantly altering the post-harvest processing dynamics. These compact mills, designed for small-scale farmers, not only optimize efficiency but also enhance the quality of rice production. Key advantages include:

- Cost-Effectiveness: The initial investment for mini rice mills is significantly lower than larger installations, making them accessible to a broader segment of farmers.

- Portability and Flexibility: Their small size allows for easy transport and adaptability to various farming settings, ensuring that rice processing is closer to the source of production.

- Quality Control: Small-scale milling can maintain better quality and freshness, as farmers can mill their rice on-site, reducing the time between harvest and processing.

In tandem with technological advancements, the evolution of these milling systems has prompted a more sustainable approach to rice cultivation. Modern mini mills incorporate elements such as:

| Feature | Benefit |

|---|---|

| Energy Efficiency | Lower operational costs and reduced environmental impact. |

| Automation | Increased precision and reduced labor requirements, allowing more focus on cultivation. |

| Customizable Settings | Farmers can adapt milling techniques to specific rice varieties, enhancing overall yield. |

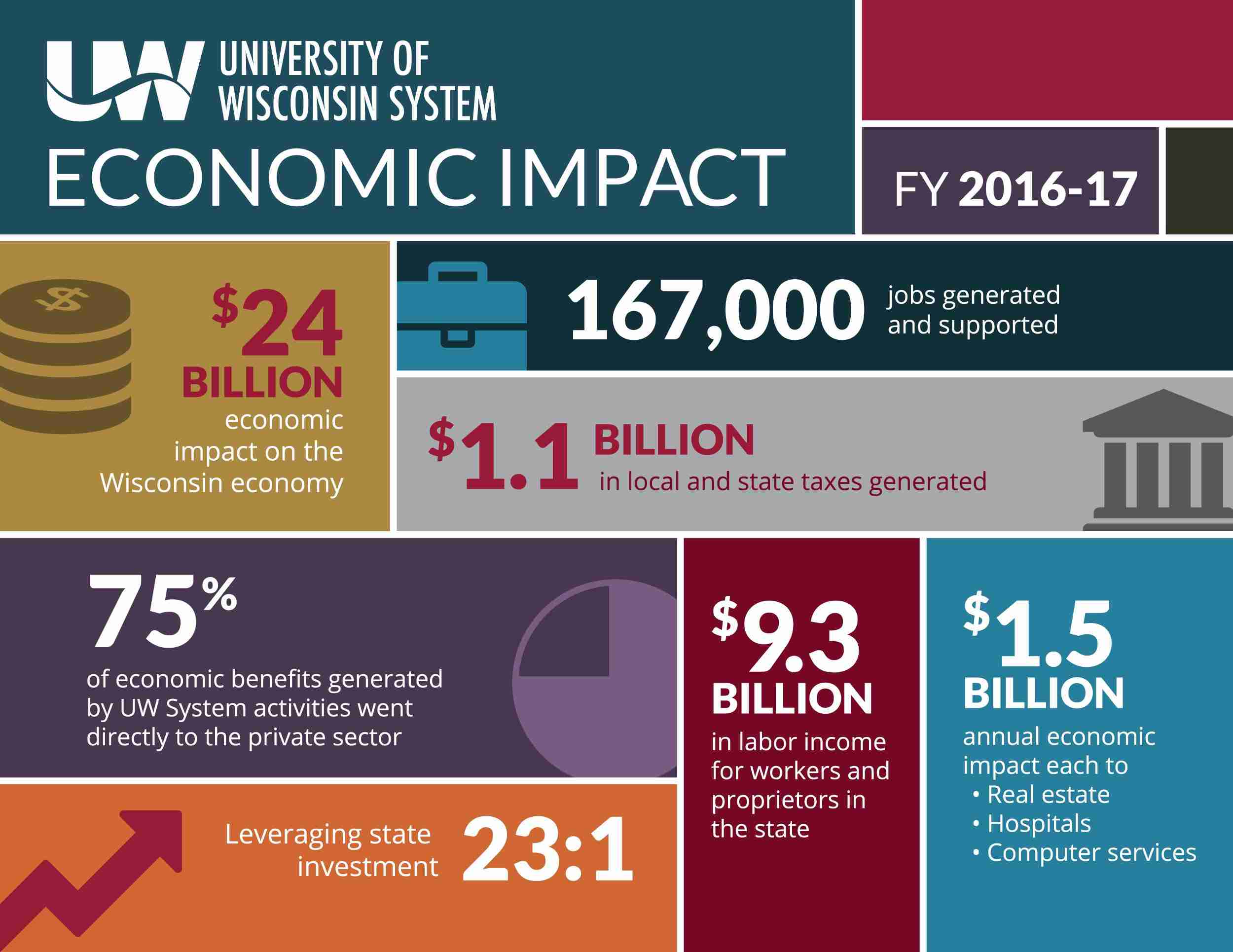

Understanding the Economic Benefits of Mini Rice Milling Operations

The economic landscape of rice farming is undergoing significant transformation with the introduction of mini rice milling operations. These compact milling systems not only enable farmers to process their own rice efficiently but also open avenues for entrepreneurship. By streamlining processing costs, these mini-mills help farmers retain a larger portion of their profits. The benefits of implementing such operations include:

- Cost Reduction: Lower transportation and processing costs due to proximity.

- Job Creation: Opportunities for local employment in milling and related services.

- Quality Control: Farmers can ensure high-quality processing tailored to market demands.

- Community Development: Enhanced local economy through increased processing capabilities.

Moreover, the rise of mini rice mills can contribute significantly to rural development. These operations can act as hubs for additional services such as storage, distribution, and marketing, fostering a more integrated agricultural ecosystem. The following table illustrates the potential impact of mini mills on local economies:

| Impact Area | Before Mini Mill | After Mini Mill |

|---|---|---|

| Processing Time | 1-2 days | 1-2 hours |

| Job Opportunities | 5 | 15+ |

| Profits Retained | 30% | 60% |

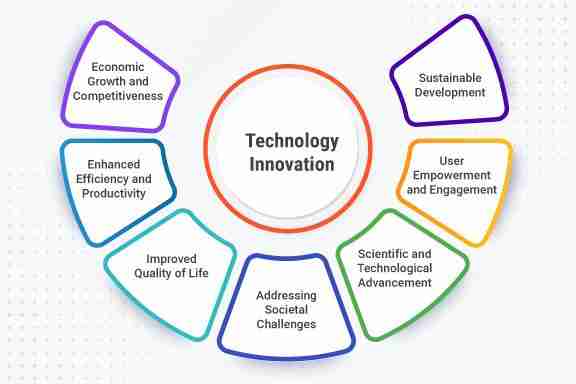

Technological Innovations Shaping the Future of Mini Rice Mills

Recent technological advancements have revolutionized the functioning and efficiency of mini rice mills, making them an essential asset for small-scale farmers and agricultural entrepreneurs. These innovations enhance productivity and reduce labor costs through automation and smart technology integration. Key developments include:

- Automated Operations: Mini rice mills now incorporate automated systems that streamline processing, minimize human intervention, and ensure consistent quality.

- Energy Efficiency: Modern designs focus on low energy consumption, utilizing innovative machinery that reduces the carbon footprint while optimizing output.

- Smart Monitoring: IoT-enabled devices allow for real-time monitoring of processing conditions and environmental variables, enabling better decision-making and timely interventions.

Additionally, the introduction of mobile and modular mini rice mills has expanded accessibility for rural areas. These compact machines can be easily transported and set up in various locations, making rice milling more convenient for remote communities. The economic potential is further boosted through:

| Feature | Benefits |

|---|---|

| Modular Design | Easy relocation and quick setup |

| Low Maintenance | Cost savings over time with reliable machinery |

| User-Friendly Interfaces | Accessible operation for non-technical users |

Best Practices for Implementing mini rice mill Plants Successfully

To ensure the successful implementation of mini rice mill plants, a series of best practices must be adhered to. Firstly, conducting thorough market research is crucial. Understanding the local demand for rice and the specific preferences of consumers will enable entrepreneurs to tailor their operations accordingly. Key aspects of this research may include:

- Identifying local rice varieties.

- Evaluating competition in the area.

- Establishing potential partnerships with farmers and suppliers.

Secondly, investing in quality machinery and efficient processing techniques can significantly impact productivity and output quality. Selecting modern equipment that offers higher milling efficiency can save both time and resources, maximizing profitability. It is essential to focus on:

- Regular maintenance schedules for machinery.

- Training staff on best operational practices.

- Adopting sustainable processing methods to minimize waste.

| Best Practice | Description |

|---|---|

| Market Research | Analyze local rice demand and consumer preferences. |

| Quality Machinery | Invest in efficient and modern milling equipment. |

| Staff Training | Provide adequate training on operation and maintenance. |

| Sustainability Practices | Implement eco-friendly methods to reduce waste. |

The Conclusion

the rise of mini rice mill plants marks a significant turning point in the agricultural landscape, illuminating a path toward greater sustainability and efficiency. These compact facilities not only empower small-scale farmers by providing them with access to modern milling technology, but they also enhance local economies, ensuring that communities thrive. As we look to the future, the success of mini rice mills serves as a beacon of innovation and resilience, reminding us that even the simplest of ideas can transform harvests and lives. As stakeholders in the agricultural sector continue to adapt and evolve, the lessons learned from this burgeoning trend will undoubtedly pave the way for a more sustainable and equitable food system. With each harvest, we are reminded that change is not only possible but essential for nourishing generations to come.